A method for obtaining in vitro cultured cells/cell thin layers by irradiation with visible light

An in vitro culture and visible light technology, applied in the direction of epidermal cells/skin cells, cell culture support/coating, tissue culture, etc., can solve the problems of cytotoxic genes, mutations, etc., and achieve simple operation, easy implementation, and good signal transmission Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] On the surface of the above-mentioned monocrystalline silicon substrate (p / n junction depth 0.3 μm, phosphorus diffusion), osteoblasts were cultured in vitro, and the seeding density was 3×10 4 piece / cm 2 , placed in a cell incubator with a constant temperature of 37 degrees Celsius and 5% carbon dioxide for 1 day, the wavelength was 400-800 nanometers, and the intensity was 30mW / cm 2 95% of the cells can be detached from the surface after 20 minutes of irradiation with visible light from the top of the cell culture vessel. figure 1 and figure 2 Confocal laser micrographs of cells cultured in Example 1 before and after visible light were observed by confocal laser microscopy. Compared figure 1 and figure 2 , it can be seen that a large number of cells detach after being irradiated by visible light, indicating that visible light achieves the detachment of single cells.

Embodiment 2

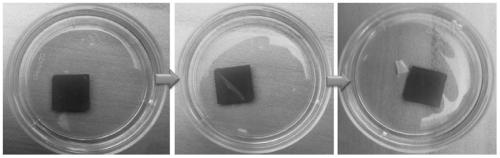

[0029] On the surface of the above polysilicon substrate (p / n junction depth 0.5 μm, phosphorus diffusion), osteoblasts were cultured in vitro, and the seeding density was 1×10 5 piece / cm 2 , placed in a cell incubator with a constant temperature of 37 degrees Celsius and 5% carbon dioxide and cultured for 5 days, the cells formed a membrane, with a wavelength of 400-800 nanometers and an intensity of 50mW / cm 2 Visible light is incident from the top of the cell culture vessel and irradiated for 10 minutes to detach the cell sheet from the surface. image 3 It is the photos before and after the cultured cell sheet in Example 2 observed by Nikon camera under visible light. It can be seen that the entire cell sheet is completely desorbed after being irradiated with visible light.

Embodiment 3

[0031] On the surface of the above amorphous silicon substrate (p / n junction depth 0.9 μm, phosphorus diffusion), osteoblasts were cultured in vitro at a seeding density of 5×10 5 piece / cm 2 After being cultured in a cell incubator with a constant temperature of 37 degrees Celsius and 5% carbon dioxide for 3 days, the cells form a membrane, with a wavelength of 400-800 nanometers and an intensity of 70mW / cm 2 Visible light is incident from the top of the cell culture vessel and irradiated for 8 minutes to detach the cell sheet from the surface. Figure 4 It is the migratory fluorescent image of the cultured cell sheet in Example 3 observed by a fluorescence microscope after being desorbed under visible light and then cultured for 2 days. It can be seen that the cell sheet desorbed by visible light can crawl out new cells well after re-cultivation, and maintain good cell shape and vitality, indicating that the cell sheet desorbed by visible light maintains good re-migration p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com