Preparation method of novel heavy metal ion adsorbent

An adsorbent and heavy metal technology, applied in alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve the problems of difficult separation, low adsorption efficiency, and small adsorption capacity, and achieve high adsorption efficiency and high adsorption capacity Large and strong adsorption capacity of heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Mix 20 parts of 10% 3-aminopropyltriethoxysilane (APTES) aqueous solution with acetic acid solution to obtain combined solution A, the amount of acetic acid solution added makes the pH value of combined solution A 4, Then mix the combination solution A with 10 parts of glycerin to obtain the combination solution B, then put the combination solution B in a beaker and stir thoroughly and add 0.4 parts of FeO nanoparticles to obtain the mixed solution C, mix the mixed solution C, and oscillate with 200W ultrasonic 1min;

[0025] 2) Put the ultrasonically oscillated mixed solution C on a constant temperature magnetic stirrer for constant temperature stirring reaction, the reaction temperature is 90°C, the reaction time is 3h, after the reaction is completed, cool to room temperature, and then add citric acid to the mixed solution C respectively 20 parts and 20 parts of pyridine to obtain the reaction solution D. Stir the reaction solution D at a constant temperature for ...

Embodiment 2

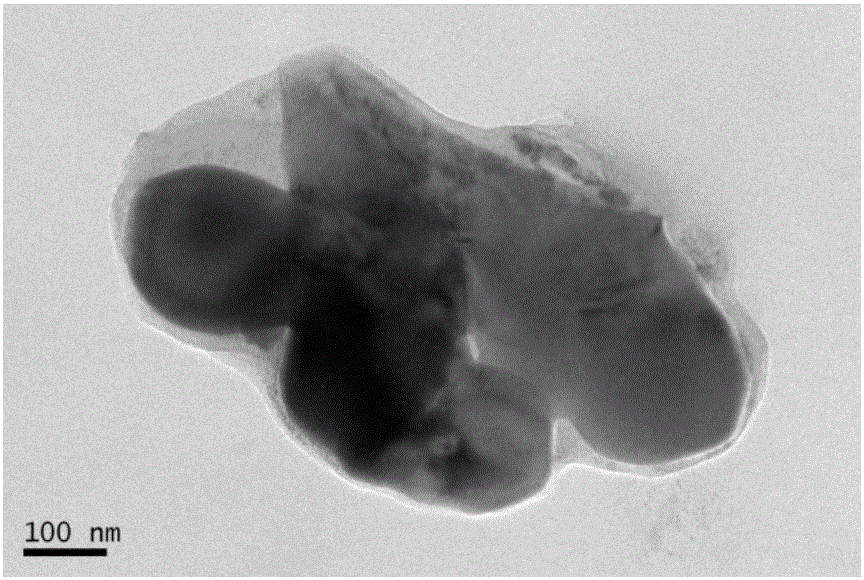

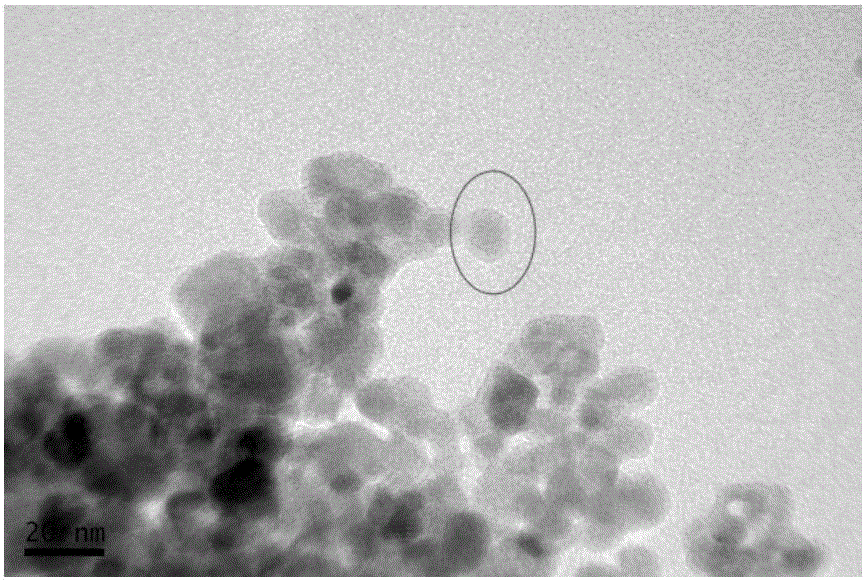

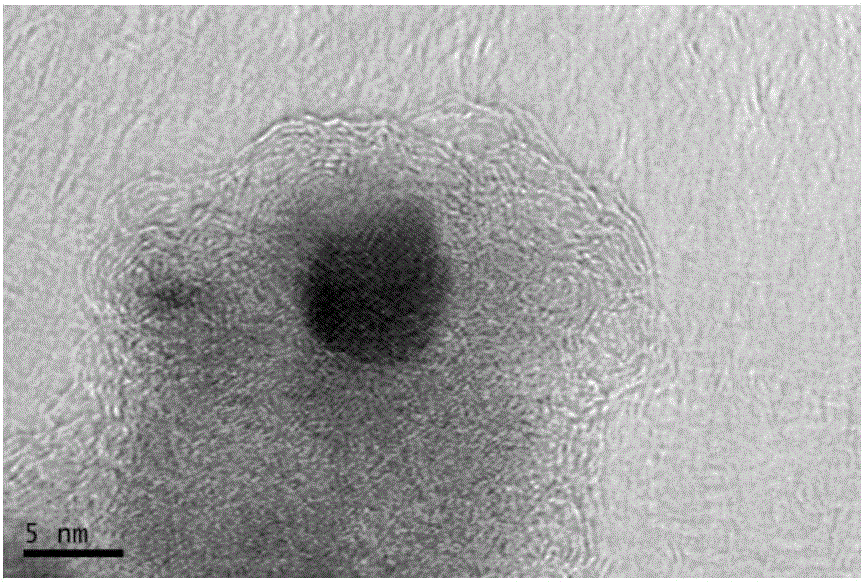

[0028] Such as Figure 1-4 As shown, the preparation method in this example is: 1) 20 parts of γ-glycidyl etheroxypropyltrimethoxysilane aqueous solution with a mass fraction of 10% is mixed with acetic acid solution to obtain combination liquid A, and the acetic acid solution is added amount so that the pH of combination liquid A is 4, and then mix combination liquid A and 10 parts of glycerin to obtain combination liquid B, then place combination liquid B in a beaker and stir thoroughly and add Fe 2 o 3 0.4 parts of nanoparticles to obtain a mixed solution C, mix the mixed solution C, and 200W ultrasonic vibration for 1min;

[0029] 2) Put the ultrasonically oscillated mixed solution C on a constant temperature magnetic stirrer for constant temperature stirring reaction, the reaction temperature is 90°C, the reaction time is 3h, after the reaction is completed, cool to room temperature, and then add citric acid to the mixed solution C respectively 20 parts and 20 parts of ...

Embodiment 3

[0032] 1) 10 parts of γ-glycidyl etheroxypropyl trimethoxysilane with a mass fraction of 10% and 15 parts of an aqueous solution of γ-(methacryloyloxy)propyl trimethoxysilane with a mass fraction of 10% The mixed solution is mixed with the acetic acid solution to obtain the combination solution A, the amount of the acetic acid solution added makes the pH value of the combination solution A 4, and then the combination solution A and 25 parts of glycerin are mixed to obtain the combination solution B, and then the combination solution B is placed in Stir well in the beaker and add Fe 2 o 3 1 part of nanoparticles to obtain the mixed solution C, mix the mixed solution C, and 200W ultrasonic vibration for 1min;

[0033] 2) Put the ultrasonically oscillated mixed solution C on a constant temperature magnetic stirrer for constant temperature stirring reaction, the reaction temperature is 90°C, the reaction time is 3h, after the reaction is completed, cool to room temperature, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com