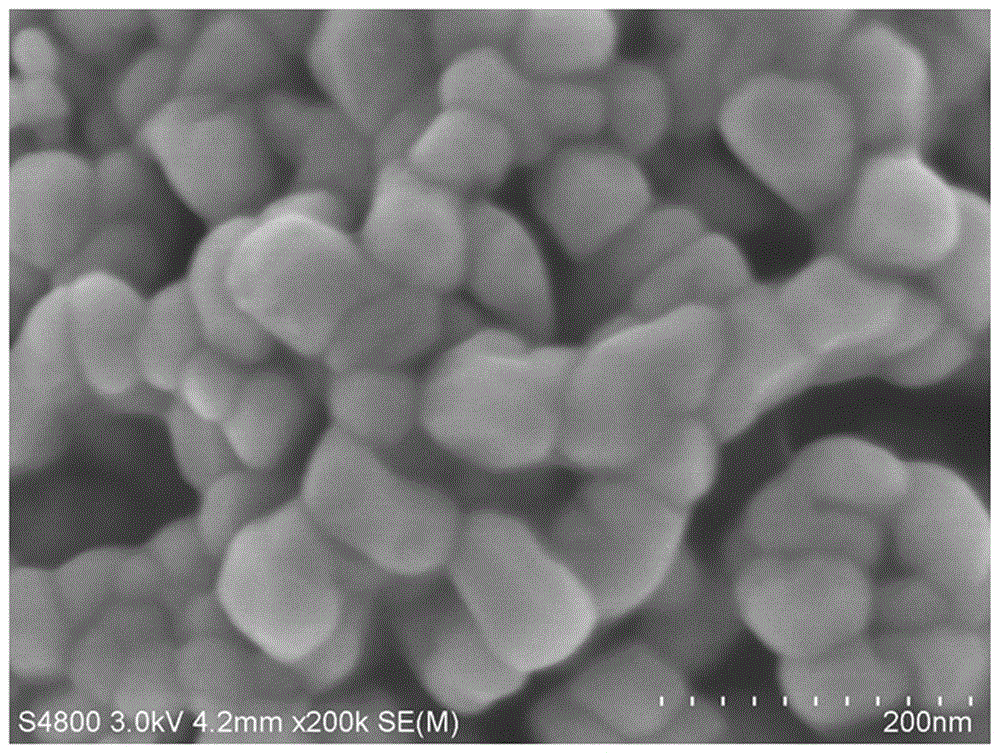

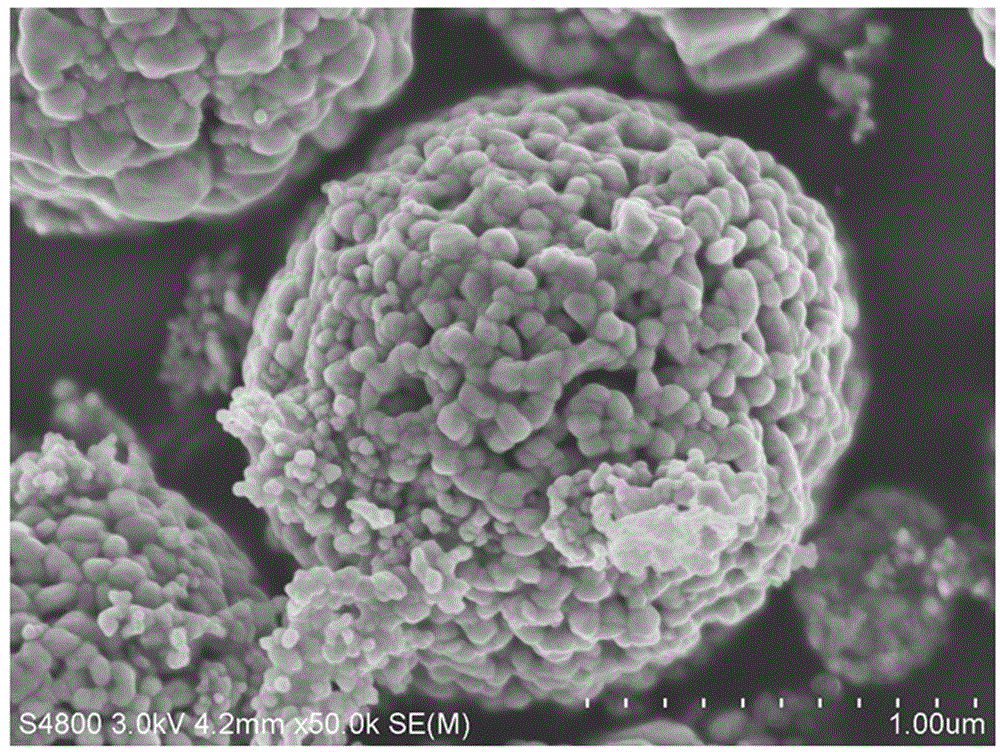

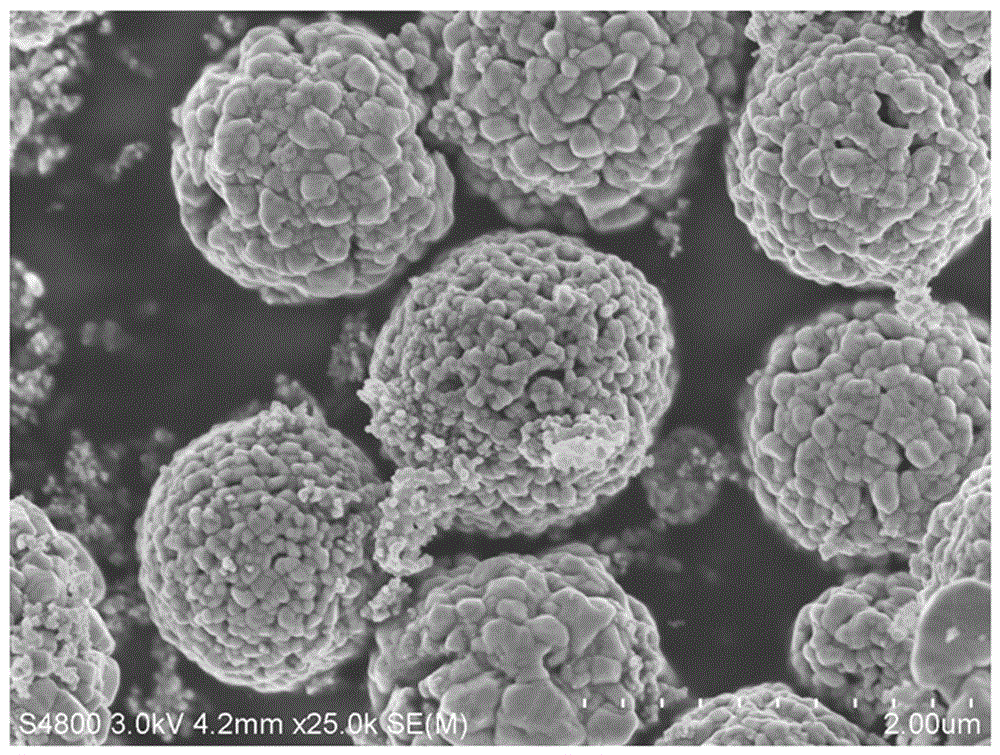

Preparing method for copper oxide spherical hierarchical structure material

A hierarchical structure, copper oxide technology, applied in copper oxide/copper hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., to achieve the effect of large specific surface area, good photocatalytic performance, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add the mineralizer ferric nitrate to the oxalic acid aqueous solution to form a transparent mixed solution. Under the conditions of a constant temperature of 30 °C and a stirring speed of 150 rpm, the copper nitrate aqueous solution is added dropwise to the above transparent mixed solution. The molar concentration of copper nitrate aqueous solution is 0.1 mol / L, and the molar concentration of oxalic acid aqueous solution is 0.5 mol / L. The molar ratio of ferric nitrate and oxalic acid is 1:50; the molar ratio of copper nitrate and oxalic acid is 1:10. The rate of dripping the copper nitrate solution was 120 drops / min, and the stirring reaction time was 30 minutes. After the reaction, it was filtered and washed. The washing liquid was a methanol-water mixed solution (volume ratio was 1:1), and the washing frequency was 10 times. Then post-drying, the drying time is 3 hours, the drying temperature is 100°C, and the heating rate is 10°C / min. The calcination is continued in...

Embodiment 2

[0037] Add the mineralizer ferric chloride to the oxalic acid aqueous solution to form a transparent mixed solution. Under the conditions of a constant temperature of 30 °C and a stirring speed of 150 rpm, the copper chloride aqueous solution is added dropwise to the above transparent mixed solution. The molar concentration of the copper chloride aqueous solution is 0.1 mol / L, and the molar concentration of the oxalic acid aqueous solution is 0.5 mol / L. The molar ratio of ferric chloride and oxalic acid is 1:50; the molar ratio of copper chloride and oxalic acid is 1:10. The dripping rate of the copper chloride solution is 120 drops / min, and the stirring reaction time is 30 minutes. After the reaction is over, filter and wash. The washing liquid is a methanol-water mixed solution (volume ratio is 1:1), and the number of washes is 10 times . Then post-drying, the drying time is 3 hours, the drying temperature is 100°C, and the heating rate is 10°C / min. The calcination is conti...

Embodiment 3

[0040] Add the mineralizer ferric nitrate to the oxalic acid aqueous solution to form a transparent mixed solution. Under the conditions of a constant temperature of 30 °C and a stirring speed of 150 rpm, the copper nitrate aqueous solution is added dropwise to the above transparent mixed solution. The molar concentration of copper nitrate aqueous solution is 0.1 mol / L, and the molar concentration of oxalic acid aqueous solution is 0.5 mol / L. The molar ratio of ferric nitrate and oxalic acid is 1:10; the molar ratio of copper nitrate and oxalic acid is 1:50. The rate of dripping the copper nitrate solution was 120 drops / min, and the stirring reaction time was 30 minutes. After the reaction, it was filtered and washed. The washing liquid was a methanol-water mixed solution (volume ratio was 1:1), and the washing frequency was 10 times. Then post-drying, the drying time is 3 hours, the drying temperature is 100°C, and the heating rate is 10°C / min. The calcination is continued in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Degradation rate | aaaaa | aaaaa |

| Degradation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com