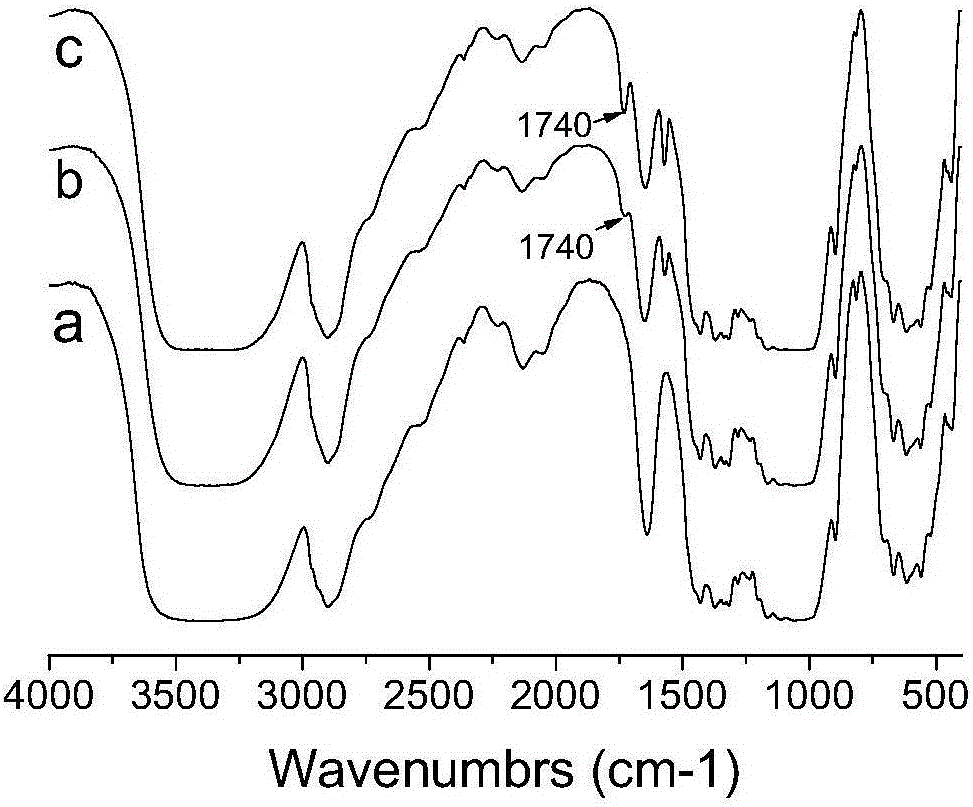

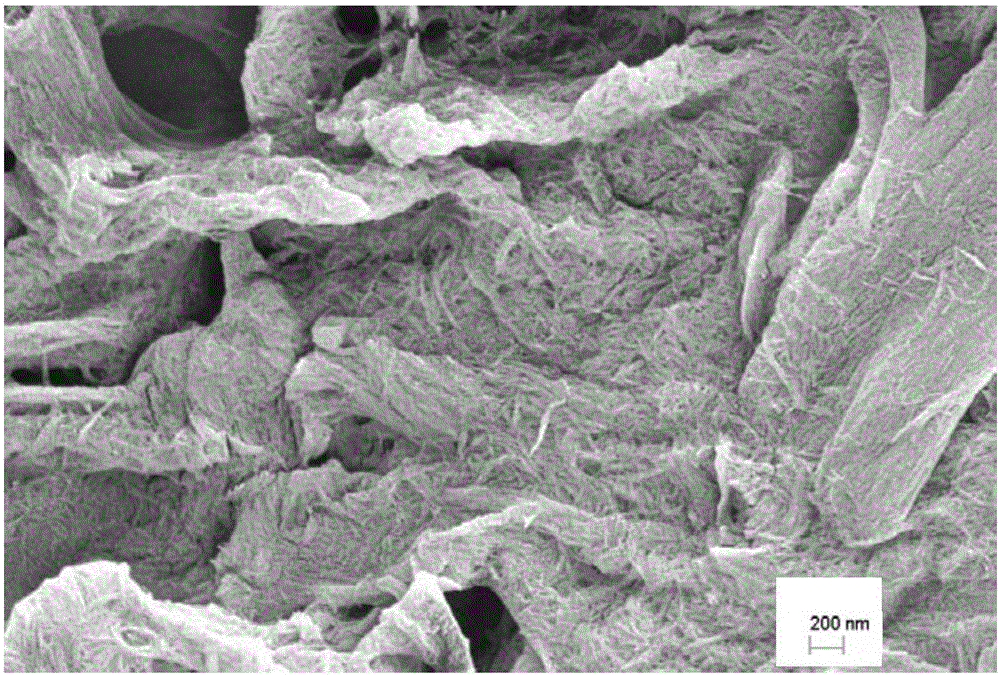

Green method of functionally modified nano-crystalline cellulose

A nanocellulose, functionalized technology, applied in fermentation and other directions, can solve the problems of harsh reaction conditions, high process requirements, complex reaction routes, etc., and achieve the effects of mild reaction conditions, high catalytic efficiency, and simple process routes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Step 1: Dry 0.5 g of microcrystalline cellulose at 50°C for 48 hours;

[0035] Step 2: Use [BMIM]HSO 4 Prepare the cellulose obtained in the first step into a mixture with a cellulose mass percentage concentration of 5%, and stir at a constant temperature of 70°C for 1 hour;

[0036] The third step: the solution obtained in the second step is lowered to room temperature, and lipase CRL and ionic liquid [BMIM]BF are added 4 ([BMIM]HSO 4 / [BMIM]BF 4 The mass ratio is 3:5) and methyl laurate, the amount of lipase CRL is 20% of the mass of microcrystalline cellulose, the molar ratio of methyl laurate to microcrystalline cellulose is 3:1, and react at 50°C for 3h; ;

[0037] Step 4: Cool the solution obtained in Step 3 to room temperature, add absolute ethanol to wash, centrifuge, remove the supernatant, and dry the obtained precipitate at 60° C. for 24 hours to obtain functionalized modified nanocellulose. The degree of substitution of the functionalized modified nanoc...

Embodiment 2

[0044] Step 1: Dry 0.5 g of microcrystalline cellulose at 50°C for 48 hours;

[0045] Step 2: Use [EMIM]HSO 4 Prepare the cellulose obtained in the first step into a mixture with a cellulose mass percentage concentration of 5%, and stir at a constant temperature of 100°C for 2 hours;

[0046] The third step: the solution obtained in the second step is lowered to room temperature, and lipase CRL and ionic liquid [BMIM]BF are added 4 ([BMIM]HSO 4 / [BMIM]BF 4 The mass ratio is 3:5) and methyl laurate, the amount of lipase CRL is 15% of the mass of microcrystalline cellulose, the molar ratio of methyl laurate to microcrystalline cellulose is 3:1, and react at 60°C for 3h; ;

[0047] Step 4: Cool the solution obtained in Step 3 to room temperature, add absolute ethanol to wash, centrifuge, remove the supernatant, and dry the obtained precipitate at 60° C. for 24 hours to obtain functionalized modified nanocellulose. As detected by acid-base titration, the degree of substitutio...

Embodiment 3

[0050] Step 1: Dry 0.5 g of microcrystalline cellulose at 80°C for 48 hours;

[0051] Step 2: Use [BMIM]HSO 4 Prepare the cellulose obtained in the first step into a mixture with a cellulose mass percentage concentration of 10%, and stir at a constant temperature of 80° C. for 3 hours;

[0052] The third step: the solution obtained in the second step is lowered to room temperature, and lipase CRL and ionic liquid [BMIM]BF are added 4 ([BMIM]HSO 4 / [BMIM]BF 4 The mass ratio is 3:5) and methyl laurate, the amount of lipase CRL is 15% of the mass of microcrystalline cellulose, the molar ratio of methyl laurate to microcrystalline cellulose is 13:1, and react at 60°C for 5h; ;

[0053] Step 4: Cool the solution obtained in Step 3 to room temperature, add absolute ethanol to wash, centrifuge, remove the supernatant, and dry the obtained precipitate at 60° C. for 24 hours to obtain functionalized modified nanocellulose. The degree of substitution of the functionalized modified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com