Preparation method of lead sulfide quantum dot photovoltaic cell

A photovoltaic cell and quantum dot technology, applied in the field of solar cells, can solve the problems of unfavorable charge transmission, low coverage of quantum dots, large particle size distribution range of quantum dots, etc., achieve simple preparation process, improve charge collection efficiency, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

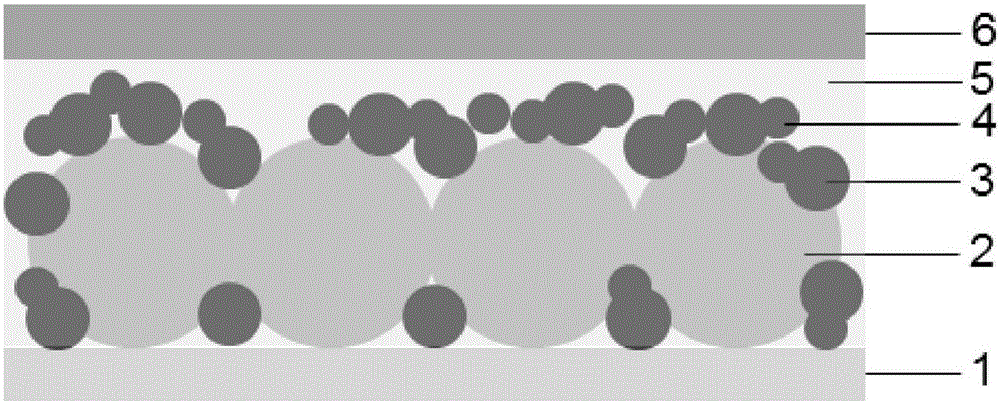

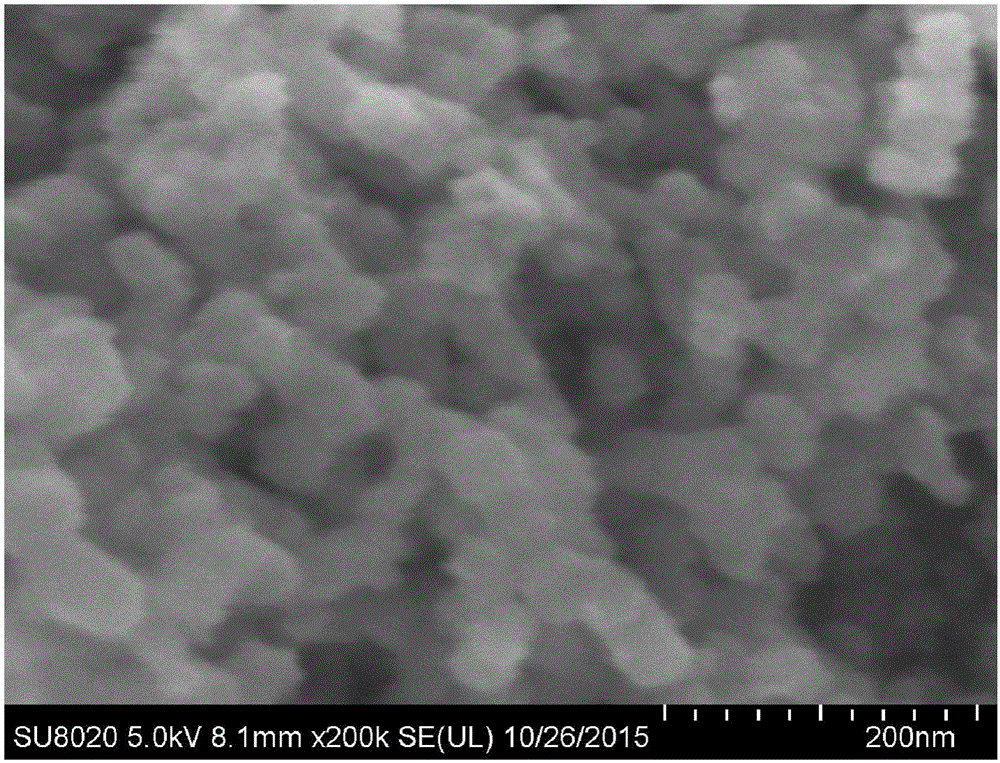

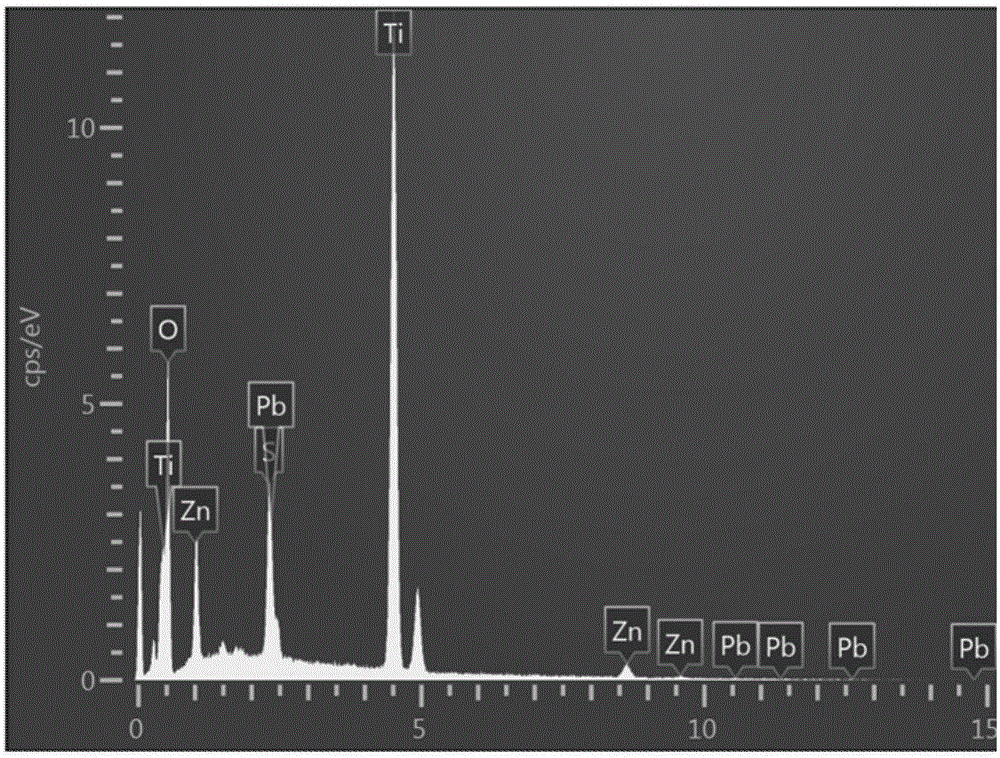

[0024] 1. TiO with a particle size of 20 nm 2 The nano-powder is mixed with a binder and a pore-forming agent to prepare a slurry, and the slurry is coated on the FTO conductive glass substrate by a knife coating method, and sintered at 500°C for 30 minutes to prepare a porous TiO with a thickness of 12 microns. 2 film;

[0025] 2. Soak the film prepared in step 1 in the mixed solution composed of lead acetate, sodium sulfite and sustained-release agent trisodium nitrilotriacetate in a molar ratio of 1:1:a (a=0.5~2), the concentration of lead acetate is 0.05 ~0.5M, keep it in the dark at 25°C for 40 minutes, take it out, rinse it with deionized water, and dry it with air;

[0026] 3. Immerse the film obtained in step 2 in the cation source precursor solution and anion source precursor solution in turn, which is a SILAR cycle, repeat the SILAR cycle 1 to 8 times, and obtain PbS quantum dot sensitized TiO 2 Photoelectrode: During each SILAR cycle, the soaking time in the catio...

Embodiment 2

[0034] 1. TiO with a certain particle size 2 , ZnO and SnO 2 The nano-powder is mixed with the binder and the pore-forming agent to prepare a slurry, and the slurry is coated on the FTO conductive glass substrate by the doctor blade method, and sintered at a certain temperature for 30 minutes to prepare porous TiO 2 film;

[0035] 2. Soak the film prepared in step 1 in a mixed solution composed of lead acetate, sodium sulfite and slow-release agent trisodium nitrilotriacetate in a molar ratio of 1:1:2. The concentration of lead acetate is 0.1M. Stand at ℃ for 40 minutes, rinse with deionized water and air dry after taking out;

[0036] 3. Immerse the film obtained in step 2 in the cation source precursor solution and the anion source precursor solution in turn, which is a SILAR cycle, repeat the SILAR cycle 4 times, and obtain PbS quantum dot sensitized TiO 2 Photoelectrode: During each SILAR cycle, the soaking time in the cation source precursor solution and the anion sour...

Embodiment 3

[0044] 1. TiO with a particle size of 20 nm 2 The nano-powder is mixed with a binder and a pore-forming agent to prepare a slurry, and the slurry is coated on the FTO conductive glass substrate by a knife coating method, and sintered at 500°C for 30 minutes to prepare a porous TiO with a thickness of 12 microns. 2 film;

[0045] 2. Soak the film prepared in step 1 in a mixed solution composed of lead acetate, sodium sulfite and slow-release agent trisodium nitrilotriacetate in a molar ratio of 1:1:2. The concentration of lead acetate is 0.1M. Stand at ℃ for 40 minutes, rinse with deionized water and air dry after taking out;

[0046] 3. Immerse the film obtained in step 2 in the cation source precursor solution and the anion source precursor solution in turn, which is a SILAR cycle, repeat the SILAR cycle 4 times, and obtain PbS quantum dot sensitized TiO 2 Photoelectrode: During each SILAR cycle, the soaking time in the cation source precursor solution and the anion source ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com