Hydrogenation catalyst using BYD hydrogenation to prepare BDO and method using BYD hydrogenation to prepare BDO

A hydrogenation catalyst and hydrogen preparation technology, which are applied in hydrogenation preparation, Raney-type catalysts, chemical instruments and methods, etc., can solve the problems of difficult separation, low mechanical strength, poor wear resistance, etc., and achieve a short external diffusion path. , the production process and equipment are simple, and the preparation method is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

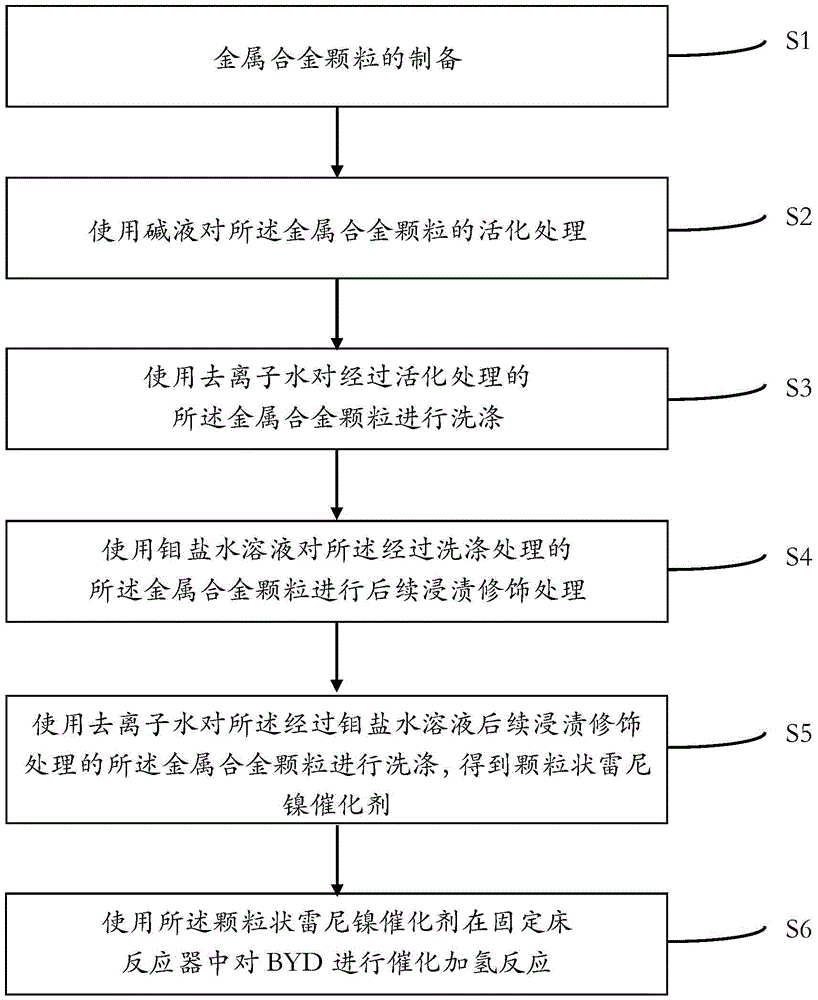

[0055] S1. Preparation of metal alloy particles;

[0056] S2. Using lye to activate the metal alloy particles;

[0057] S3. Washing the activated metal alloy particles with deionized water;

[0058] S4. Using an aqueous molybdenum salt solution to perform subsequent impregnation and modification treatment of Mo on the washed metal alloy particles;

[0059] S5. Using deionized water to wash the metal alloy particles that have been subsequently impregnated with a molybdenum salt solution to obtain a granular Raney nickel catalyst;

[0060] S6. Using the granular Raney nickel catalyst to perform the first-stage catalytic hydrogenation reaction of BYD in a fixed-bed reactor.

[0061] Among them, S1-S5 are the preparation process of the granular Raney nickel catalyst. The specific implementation method can refer to the description of the first stage of BYD catalytic hydrogenation to prepare the BDO catalyst, so it will not be described here.

[0062] S6 is specifically as follow...

Embodiment 1

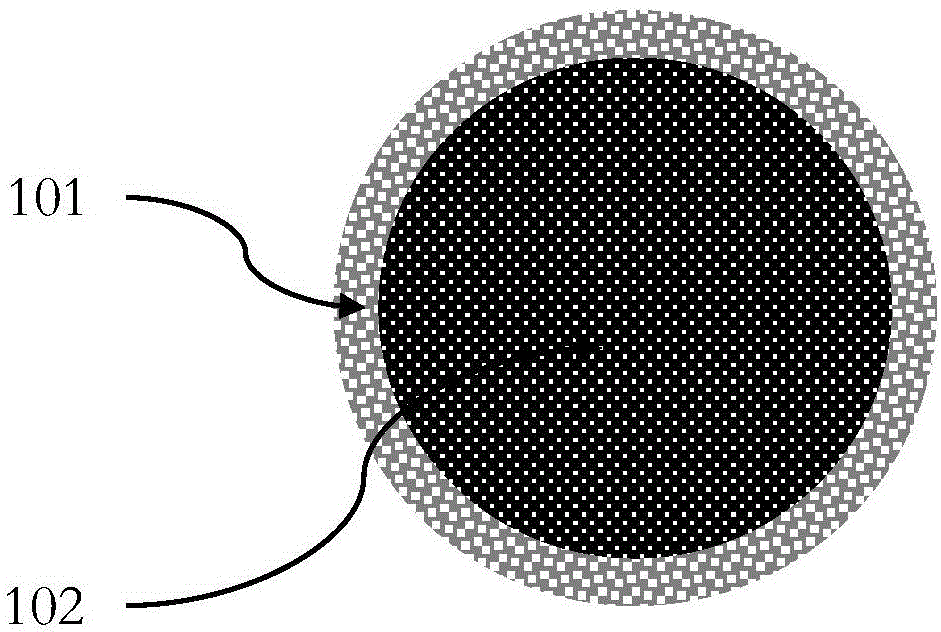

[0070] This embodiment illustrates that the average particle diameter is 5 mm, and the composition is Ni 50 Al 50 The preparation process of granular Raney nickel catalyst prepared by alkali solution activation treatment of metal alloy particles.

[0071] In a specific embodiment, it is accurately weighed that the average particle diameter is 5 mm and the composition is Ni 50 Al 50 500g of metal alloy particles, placed in a quartz glass tube with an inner diameter of 50mm, the NaOH alkali solution with a concentration of 1wt% flows from the bottom of the quartz glass tube through the metal alloy particle bed at a rate of 10L / h and then flows out from the top, NaOH alkali The weight space velocity of the liquid is 20h -1 . The bed temperature is 70°C, and the activation treatment time is 2h. After lye activation treatment, wash with deionized water at 50° C. until the pH of the solution after washing is 7-9. The average composition of the prepared granular Raney nickel ca...

Embodiment 2

[0073] This embodiment illustrates that the average particle diameter is 5 mm, and the composition is Ni 48 Al 50 Cr 2 The preparation process of granular Raney nickel catalyst prepared by alkali solution activation treatment of metal alloy particles.

[0074] In a specific embodiment, the preparation of the granular Raney nickel catalyst is carried out according to the method described in Example 1, except that the original composition of the metal alloy particles is Ni 48 Al 50 Cr 2 , the average composition of the prepared granular Raney nickel catalyst is Ni 52.7 Al 45.1 Cr 2.2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com