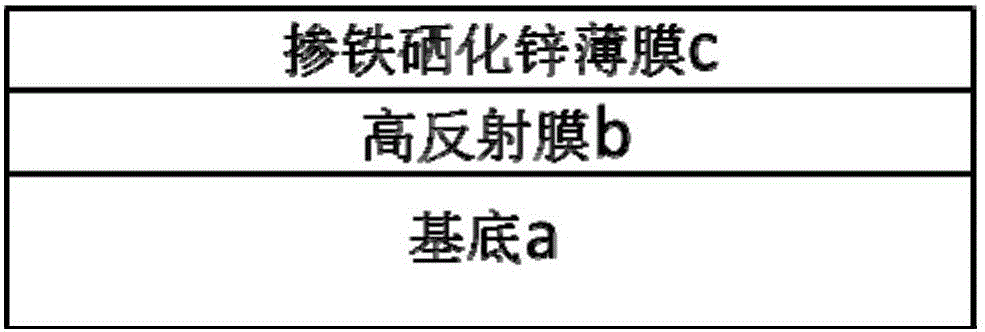

Iron-doped zinc selenide saturable absorber mirror, manufacturing method thereof, and mold-locked fiber laser composed of iron-doped zinc selenide saturable absorber mirror

A saturable absorption and zinc selenide technology, applied in the laser field, can solve the problem of low light damage threshold, achieve simple preparation process, high reliability, and reduce light scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, the quartz glass is used as the substrate, and the iron-doped zinc selenide saturable absorption mirror is prepared by using the laser pulse deposition method (PLD), including the following steps: the substrate and the gold target are respectively placed in a PLD (Pulsed laser deposition, pulsed laser deposition system) ) on the substrate support and target support in the cavity, and vacuum the cavity to no more than 1×10 -4 Pa, then raise the temperature of the substrate holder in the cavity to 400°C, turn on the femtosecond laser, and set the peak power to 2×10 10 Under the action of W laser, deposit on the substrate for 40 minutes to obtain a gold film with a thickness of 300nm; then cool to room temperature with the furnace, and replace the gold target with Fe 2+ The concentration is 1×10 17 cm -3 iron-doped zinc selenide crystal target, and then vacuum the cavity to no more than 1×10 -4 Pa, then raise the temperature of the substrate holder i...

Embodiment 2

[0037] In this embodiment, the calcium fluoride crystal substrate is used as the substrate, and the iron-doped zinc selenide saturable absorption mirror is prepared by adopting the laser pulse deposition method (PLD), which includes the following steps: the substrate and the silver target are respectively placed in the PLD (Pulsed laser deposition, Pulse laser coating system) on the substrate support and target support in the cavity, vacuum the cavity to no more than 1×10 -4 Pa, then raise the temperature of the substrate holder in the cavity to 600°C, turn on the femtosecond laser, and set the peak power to 4×10 10 Under the action of W laser, deposit on the substrate for 25 minutes to obtain a silver film with a thickness of 400nm; then cool to room temperature with the furnace, and replace the silver target with Fe 2+ The concentration is 1×10 18 cm -3 Iron-doped zinc selenide crystal target, and then vacuum the cavity to no more than 1×10 -4 Pa, then raise the temperatu...

Embodiment 3

[0039] In this embodiment, the silicon carbide crystal substrate is used as the substrate, and the iron-doped zinc selenide saturable absorption mirror is prepared by adopting the laser pulse deposition method (PLD). Coating system) on the substrate support and target support in the cavity, vacuum the cavity to no more than 1×10 -4 Pa, then raise the temperature of the substrate holder in the cavity to 800°C, turn on the femtosecond laser, and set the peak power to 4×10 10 Under the action of W laser, deposit on the substrate for 25 minutes to obtain a gold film with a thickness of 400nm; then cool to room temperature with the furnace, and replace the gold target with Fe 2+ The concentration is 1×10 19 cm -3 iron-doped zinc selenide crystal target, and then vacuum the cavity to no more than 1×10 -4 Pa, then raise the temperature of the substrate holder in the cavity to 800°C, turn on the femtosecond laser, and set the peak power to 4×10 10 Under the action of W laser, depo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com