Conductive hydrogels for affinity sensing

A hydrogel and sensor technology, applied in the field of conductive hydrogel for affinity sensing, can solve problems such as poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

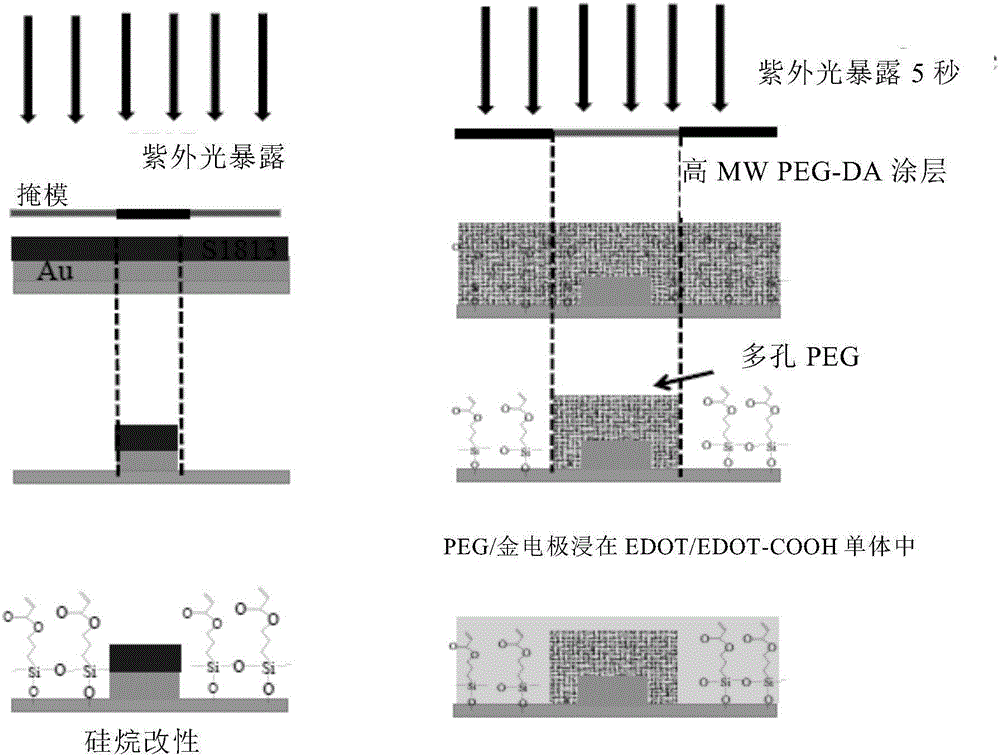

[0133] Embodiment 1: Preparation of PEDOT-polyethylene glycol hydrogel

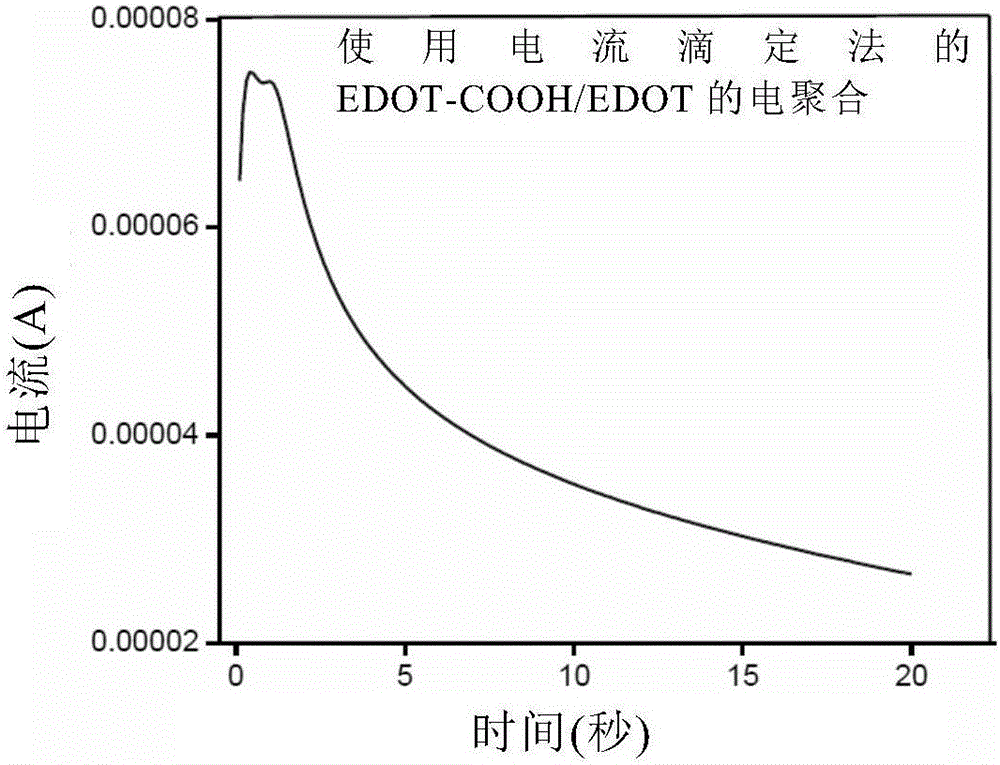

[0134] To develop immunosensors, we constructed a novel composite conductive hydrogel, which includes conductive carboxyl-functionalized PEDOT and high molecular weight PEG. Carboxyl functionalization provides bioconjugation capabilities. The biointerface was prepared by polymerizing PEG on top of miniaturized gold electrodes, followed by electropolymerization of PEDOT copolymers into porous PEG gels using aqueous microemulsions. The PEDOT / PEG copolymer is compositionally tunable and its deposition on an array of electrode surfaces is controllable. The COOH groups located on the conductive polymer chains were tailored with B-IFN-γ antibodies through active ester groups. Conductive hydrogel electrodes immobilized with antibodies were used for label-free electrochemical detection of B-IFN-γ in buffer and bovine plasma. Binding of B-IFN-γ to antibodies results in a decrease in electrochemical signal due...

Embodiment 2

[0143] Embodiment 2: preparation sensor

[0144]Gold and ITO patterned electrodes were fabricated using photolithography and wet etching methods as previously reported. Micropatterned glass slides (including photoresist on top of the gold surface) were treated with oxygen plasma for 10 min and treated in 0.05% (3-acryloyloxypropyl)trichlorosilane in toluene under a nitrogen atmosphere. solution for about 1 hour to obtain a self-assembled monolayer of silane in the glass zone. This process is described in more detail below.

[0145] Positive resist (S1813) was spin-coated (2000 rpm, 30 sec) onto a glass slide coated with a 15 nm chrome adhesion layer and a 100 nm gold layer, resulting in a thick layer of photoresist. The glass sheet coated with photoresist material was softened and baked on a hot plate at 115° C. for 1 minute, then placed in contact with a photomask, and exposed to a 365 nm ultraviolet light source. The bottom plate is then placed in a developer solution (...

Embodiment 3

[0148] Embodiment 3: pulmonary tuberculosis detection

[0149] Antibody (bovine-IFN-γ) functionalized PEDOT conductive hydrogel was placed in the electrochemical wells set in Example 2. Different concentrations of the target substance (recombinant interferon gamma) prepared in 1X PBS were introduced into the electrochemical wells and incubated for about 20 minutes. Record the cyclic voltammetry curve.

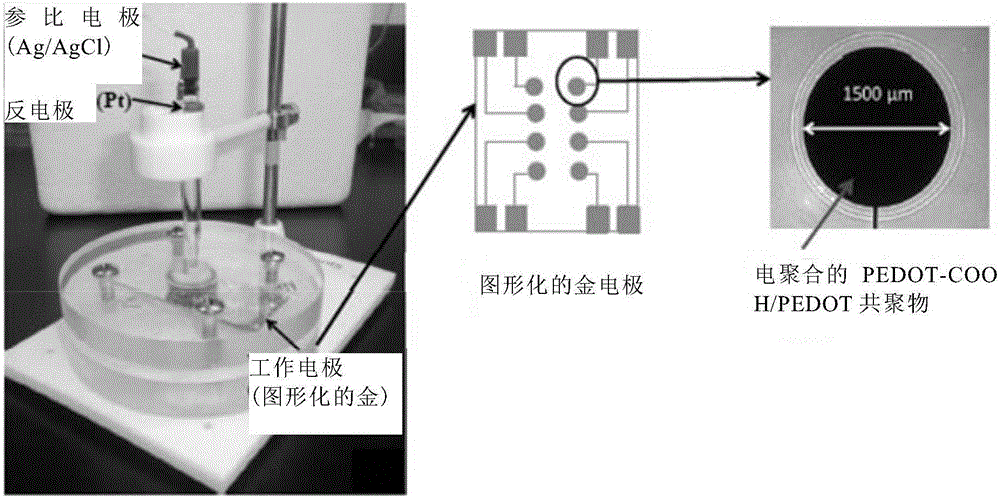

[0150] like Figure 8A As shown, each sensing electrode (antibody-functionalized conductive hydrogel on gold microelectrodes) was connected to a potentiostat through a gold contact pad. In this way, each sensing electrode is individually addressed by a potentiostat.

[0151] Gold electrodes with conductive gel on the sensing wafer were the working electrodes and were addressed by potentiostats, respectively. We used an external Ag / AgCl reference electrode and a platinum wire counter electrode. These were respectively immersed in the electrolyte solution in the electroche...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com