Phase-inversion sunscreen composition and preparation method thereof

A composition and phase inversion technology, applied in the field of daily chemicals, can solve the problems of reduced greasy feeling, reduced use feeling, slow oily feeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

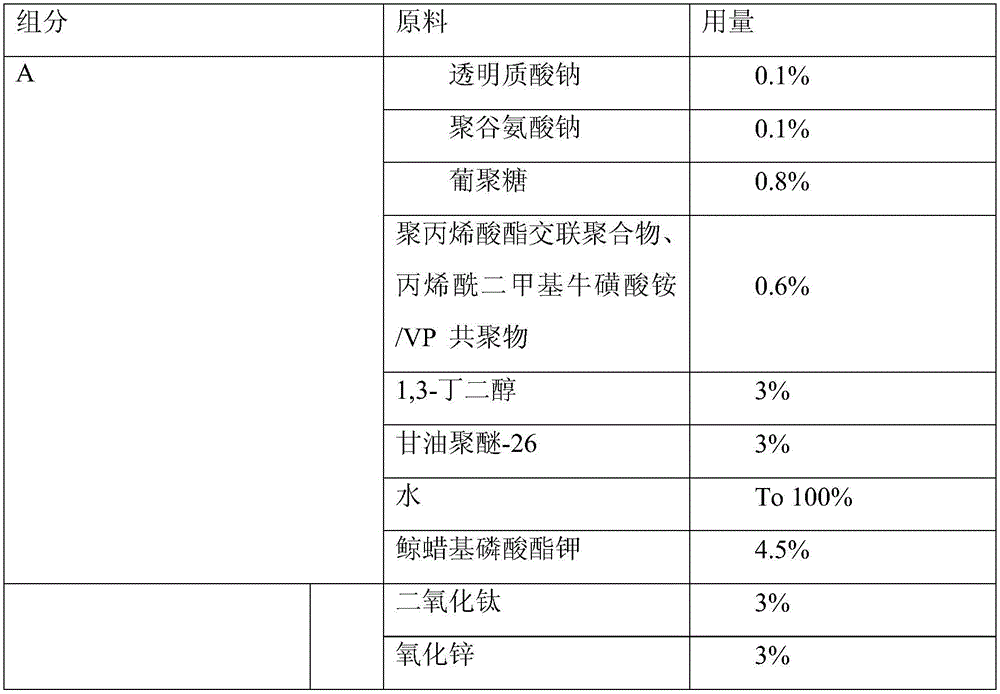

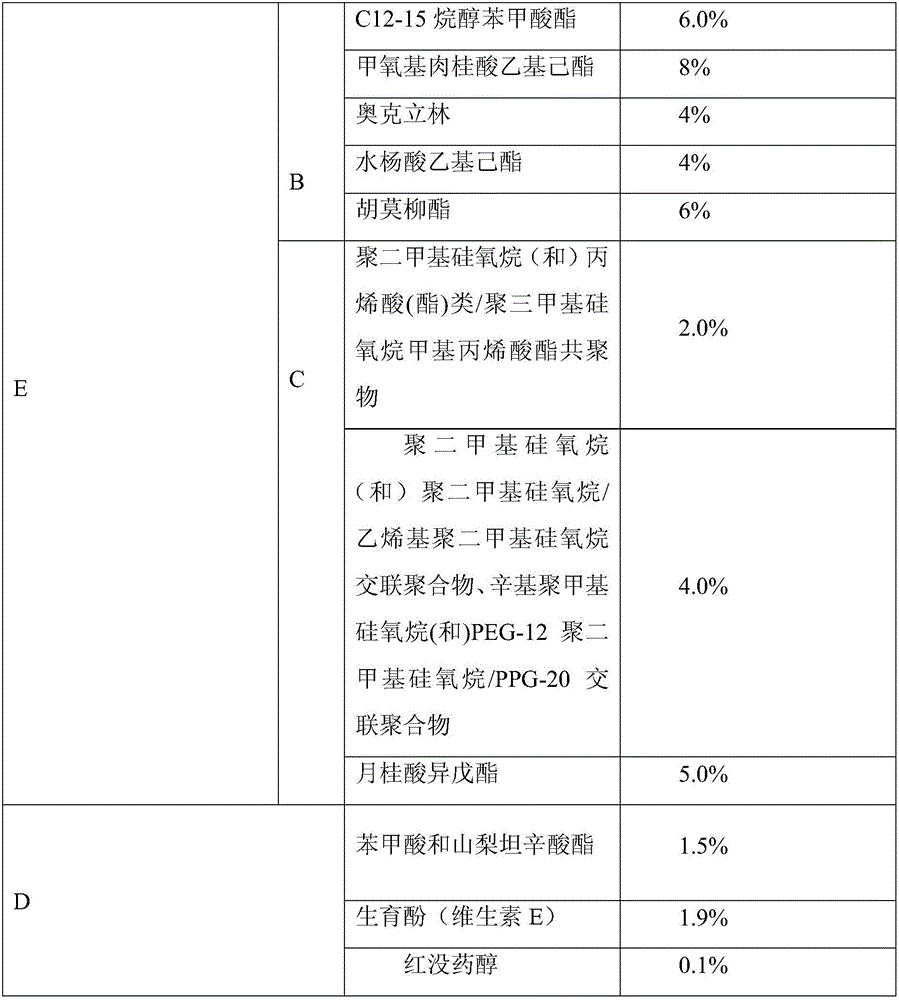

[0038] A phase-inversion sunscreen composition, comprising the raw material components and consumption of the following table 1:

[0039] The raw material components of the phase inversion sunscreen composition of table 1 embodiment 1

[0040]

[0041]

[0042] The phase-inversion sunscreen composition of above-mentioned embodiment 1, its preparation process is as follows:

[0043] 1) Sodium hyaluronate, sodium polyglutamate, dextran, polyacrylate crosslinked polymer, 1,3-butanediol for ammonium acryloyldimethyltaurate / VP copolymer, glycerol polyether -26 is pre-dispersed evenly, then add water, heat and stir to 75-85°C until completely dissolved, cool down to 50-70°C, add potassium cetyl phosphate, stir to dissolve until transparent and keep warm to obtain component A;

[0044]2) Oily titanium dioxide and oily zinc oxide are pre-dispersed evenly with C12-15 alkanol benzoate and isoamyl laurate, then add ethylhexyl methoxycinnamate, octocrylene, ethyl salicylate Hexyl ...

Embodiment 2

[0053] A phase-inversion sunscreen composition, comprising the raw material components and consumption of the following table 3:

[0054] The raw material component of the phase inversion sunscreen composition of table 3 embodiment 2

[0055]

[0056] The preparation process is the same as the method steps of the above-mentioned embodiment 1.

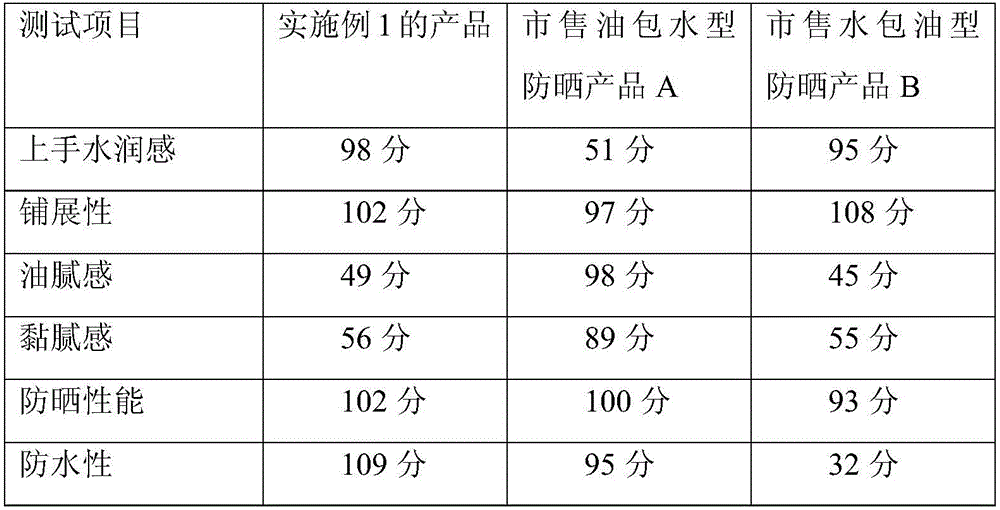

[0057] The prepared sunscreen composition, the commercially available water-in-oil type sunscreen product A, and the commercially available oil-in-water type sunscreen product B were tested by 12 people (half male and half male, aged between 20-45 years old) successively, and the obtained The results are based on the 10-point system for each test item, and the scores obtained by summing each test item are shown in Table 4 below:

[0058] The product of the present embodiment of table 4 compares with the test item scores of two kinds of commercially available products

[0059]

[0060] As can be seen from the results in Table 4, ...

Embodiment 3

[0062] A phase-inversion sunscreen composition, comprising the raw material components and consumption of the following table 5:

[0063] The raw material component of the phase inversion sunscreen composition of table 5 embodiment 3

[0064]

[0065] According to the method steps of the above-mentioned Example 1, the prepared sunscreen composition A, the commercially available water-in-oil type sunscreen product B, and the commercially available oil-in-water type sunscreen product C were successively prepared by 12 people (half male and half male, aged between 1 and 2). 20-45 years old) to carry out the test, the results obtained are based on the 10-point system for each test item, and the scores obtained by summing each test item are shown in Table 6:

[0066] The product of the present embodiment of table 6 compares with the test item scores of two kinds of commercially available products

[0067]

[0068]

[0069] As can be seen from the results in Table 6, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com