Regeneration method of deactivated catalyst

A technology for deactivating catalysts and catalysts, applied in catalyst regeneration/reactivation, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of molecular sieve structure damage, metal platinum aggregation, large solvent consumption, etc., to avoid damage and improve dispersion. , to avoid the effect of aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

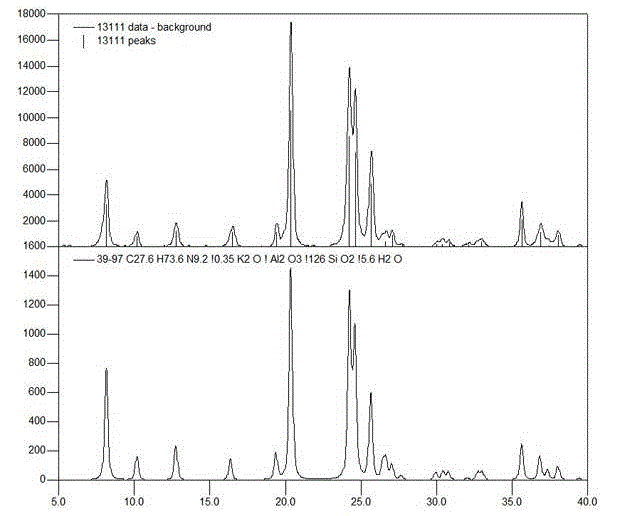

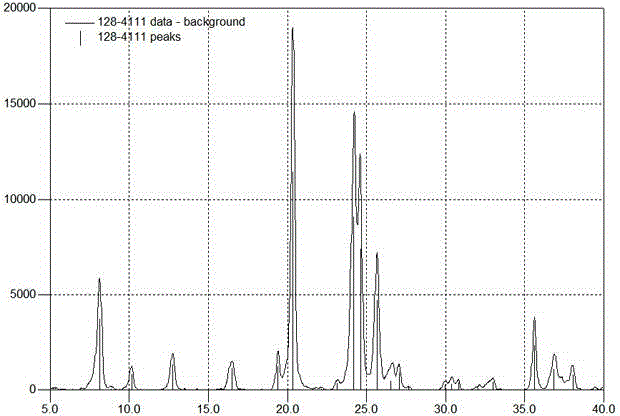

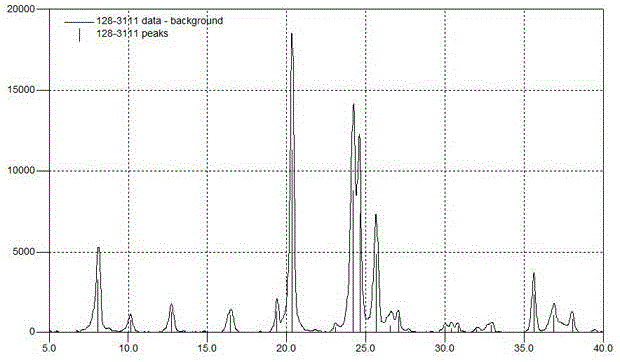

Image

Examples

Embodiment 1

[0040] Preparation of Catalyst E-1 of the Invention.

[0041] Add 1450mL of organic solvent (the volume ratio of ethanol and benzene is 2:1) into a 2000mL flask to treat 200mL of deactivated catalyst FD-1 after industrial operation, and the number of the catalyst after distillation for 2.0h is Ca-1.

[0042] Take 120g of Ca-1 catalyst, add 14.4g of zinc nitrate (Zn content 5.0wt%) solution for impregnation, and prepare a Zn-containing sample with an atomic ratio of Zn to Pt of 4:1, and then perform programmed charcoal burning in an air atmosphere , the specific steps are to raise the temperature to 250°C for 10 hours at a heating rate of 3°C / min, and then continue to raise the temperature to 410°C for 3 hours at a heating rate of 3°C / min. The obtained catalyst is numbered Ea-1.

[0043] The above-mentioned catalyst Ea-1 was reduced in a hydrogen atmosphere, and the specific conditions were: the hydrogen pressure was 3.5 MPa, the reduction temperature was 430° C., and the reduc...

Embodiment 2

[0047] Preparation of Catalyst E-2 of the Invention.

[0048] Add 1450mL of organic solvent (the volume ratio of ethanol and benzene is 1:1) into a 2000mL flask to treat 200mL of deactivated catalyst FD-1 after industrial operation, and the catalyst number after distillation for 2h is Ca-2.

[0049]Take 120g of Ca-2 catalyst, add 8.8g of zinc acetate (Zn content 10.0wt%) solution for impregnation, and prepare a Zn-containing sample, wherein the atomic ratio of Zn to Pt is 5:1, and then perform program control in an air atmosphere For charcoal burning, the specific steps are to raise the temperature to 230°C for 10 hours at a heating rate of 3°C / min, and then continue to raise the temperature to 420°C for 3 hours at a heating rate of 3°C / min. The obtained catalyst is numbered Eb-1.

[0050] The above-mentioned catalyst Eb-1 was reduced in a hydrogen atmosphere, and the specific conditions were: the hydrogen pressure was 4.5 MPa, the reduction temperature was 480° C., and the re...

Embodiment 3

[0054] Preparation of Catalyst E-3 of the Invention.

[0055] Add 1450mL of organic solvent (the volume ratio of gasoline and kerosene is 1:1) into a 2000mL flask to treat 200mL of deactivated catalyst FD-1 after industrial operation, and the number of the catalyst after distillation for 2h is Cb-1.

[0056] Take 120g of Cb-1 catalyst, add 70.5g of zinc nitrate (Zn content 2.0wt%) solution for impregnation, and prepare a Zn-containing sample, wherein the atomic ratio of Zn to Pt is 8:1, and then perform program control in an air atmosphere For charcoal burning, the specific steps are to raise the temperature to 280°C for 8 hours at a heating rate of 3°C / min, and then continue to raise the temperature to 350°C for 5 hours at a heating rate of 3°C / min. The obtained catalyst is numbered Ec-1.

[0057] The above-mentioned catalyst Ec-1 was reduced under a hydrogen atmosphere, and the specific conditions were: the hydrogen pressure was 2.5 MPa, the reduction temperature was 450° C....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com