A low alcohol high -efficiency moisturizing solution and its preparation method

A fountain solution and high-efficiency technology, applied in the field of low-alcohol and high-efficiency fountain solution and its preparation, to achieve good surface tension, meet application requirements, and good printing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

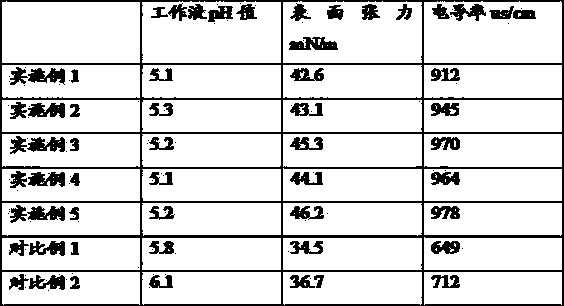

Examples

Embodiment 1

[0024] The preparation method of low-alcohol high-efficiency fountain solution, the steps of the preparation method are:

[0025] Step 1. Weigh each raw material according to the above parts by weight: 4 parts of gelatin, 3 parts of potassium citrate, 2 parts of sodium bicarbonate, 2 parts of graphene oxide, 1 part of sodium chloride, 4 parts of sodium succinate, diacetone-D - 3 parts of mannitol, 3 parts of octyl dodecyl glucoside, 2 parts of isomeric alcohol polyoxyethylene ether, 4 parts of polyoxyethylene lauryl ether, 3 parts of rhamnolipid, 2 parts of borax, 4 parts of tartaric acid 1 part, magnesium acetate 1 part, aluminum potassium sulfate 2 parts, sodium dodecylbenzene sulfonate 2 parts, hydroxymethyl cellulose 1 part, Tween-60 2 parts, polyethylene glycol 8 parts, n-butanol 6 parts 256 parts of soft water;

[0026] Step 2, adding graphene oxide into soft water, tartaric acid and sodium dodecylbenzenesulfonate, and ultrasonically dispersing evenly to obtain a graphe...

Embodiment 2

[0031] The preparation method of low-alcohol high-efficiency fountain solution, the steps of the preparation method are:

[0032] Step 1. Weigh each raw material according to the above parts by weight: 13 parts of gelatin, 9 parts of potassium citrate, 8 parts of sodium bicarbonate, 5 parts of graphene oxide, 6 parts of sodium chloride, 9 parts of sodium succinate, diacetone- 7 parts of D-mannitol, 8 parts of octyl dodecyl glucoside, 7 parts of isomeric alcohol polyoxyethylene ether, 9 parts of polyoxyethylene lauryl ether, 8 parts of rhamnolipid, 6 parts of borax, tartaric acid 9 parts, magnesium acetate 5 parts, aluminum potassium sulfate 6 parts, sodium dodecylbenzene sulfonate 5 parts, hydroxymethyl cellulose 5 parts, Tween-60 7 parts, polyethylene glycol 18 parts, n-butanol 15 parts, 46 parts of soft water;

[0033] Step 2, adding graphene oxide into demineralized water, tartaric acid and sodium dodecylbenzenesulfonate, and ultrasonically dispersing evenly to obtain a gr...

Embodiment 3

[0038] The preparation method of low-alcohol high-efficiency fountain solution, the steps of the preparation method are:

[0039] Step 1. Weigh each raw material according to the above parts by weight: 6 parts of gelatin, 4 parts of potassium citrate, 3 parts of sodium bicarbonate, 3 parts of graphene oxide, 2 parts of sodium chloride, 5 parts of sodium succinate, diacetone- 4 parts of D-mannitol, 5 parts of octyl dodecyl glucoside, 4-6 parts of isomeric alcohol polyoxyethylene ether, 5-8 parts of polyoxyethylene lauryl ether, 4 parts of rhamnolipid, borax 3 parts, 5 parts of tartaric acid, 2 parts of magnesium acetate, 3 parts of potassium aluminum sulfate, 3.2 parts of sodium dodecylbenzenesulfonate, 2 parts of hydroxymethyl cellulose, 3 parts of Tween-60, 9 parts of polyethylene glycol, 8 parts of n-butanol, 28 parts of soft water;

[0040] Step 2, adding graphene oxide into soft water, tartaric acid and sodium dodecylbenzene sulfonate, and ultrasonically dispersing evenly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com