Treatment method of O-xylene liquid phase oxidation residues

A treatment method and xylene liquid technology, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of waste of non-renewable resources, complex components, environmental pollution, etc., and achieve obvious industrial advantages and reaction conditions Mild, utilization-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

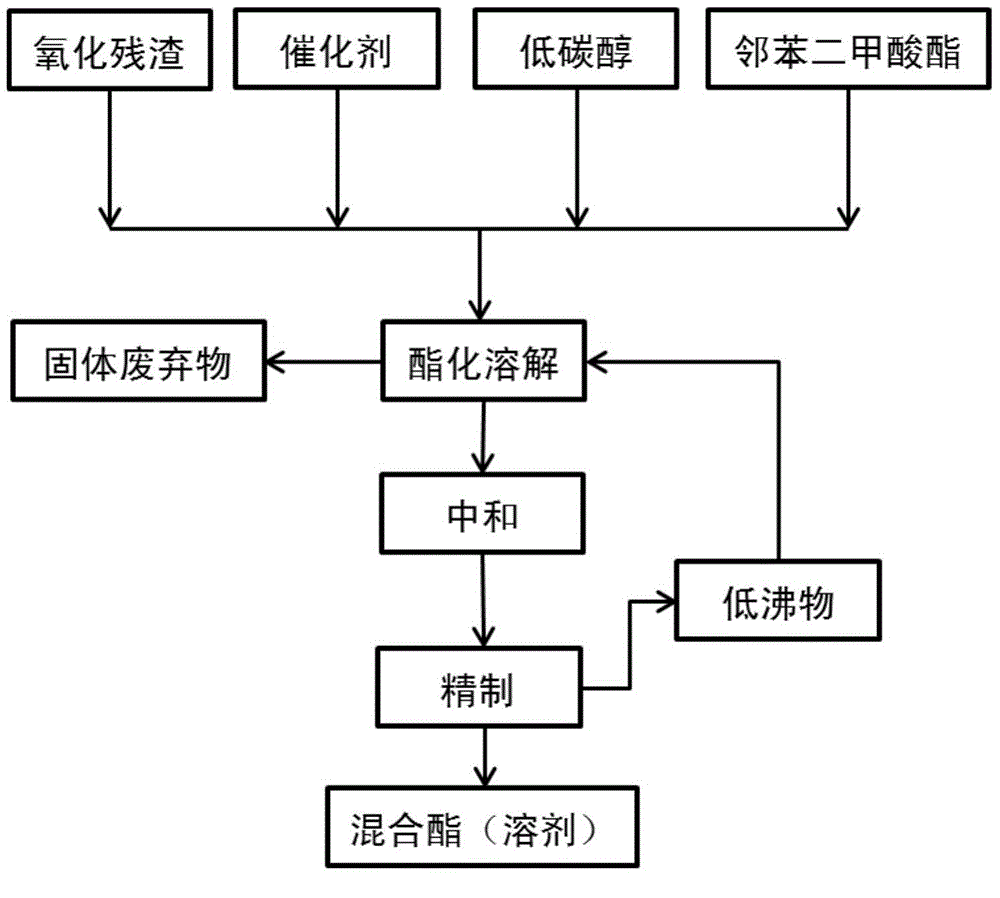

[0020] Such as figure 1 As shown, weigh 100g o-xylene oxidation solid residue, add 200g dimethyl phthalate, 100g methanol, 5g 98% concentrated sulfuric acid, react in an autoclave at 150°C for esterification and dissolution process, the pressure is 1.5Mpa , the reaction time is 5h. After the process is over, the liquid is mixed crude ester after solid-liquid separation, and the mass of the remaining oxidized solid residue after drying is 43.8g. It can be calculated that the removal rate of oxidized residue is 56.2%. The mixed crude esters enter the neutralization step, add 40mL of 5% NaOH solution to stir and neutralize, and then divide the water. The mixed crude esters after water division are neutral, and then enter the rectification process, and the low boiling The low boilers obtained are mainly unreacted methanol, which can be mixed with phthalates and recycled as reactants of the esterification reaction. The bottom of the tower is the obtained mixed ester, which can ent...

Embodiment 2-7

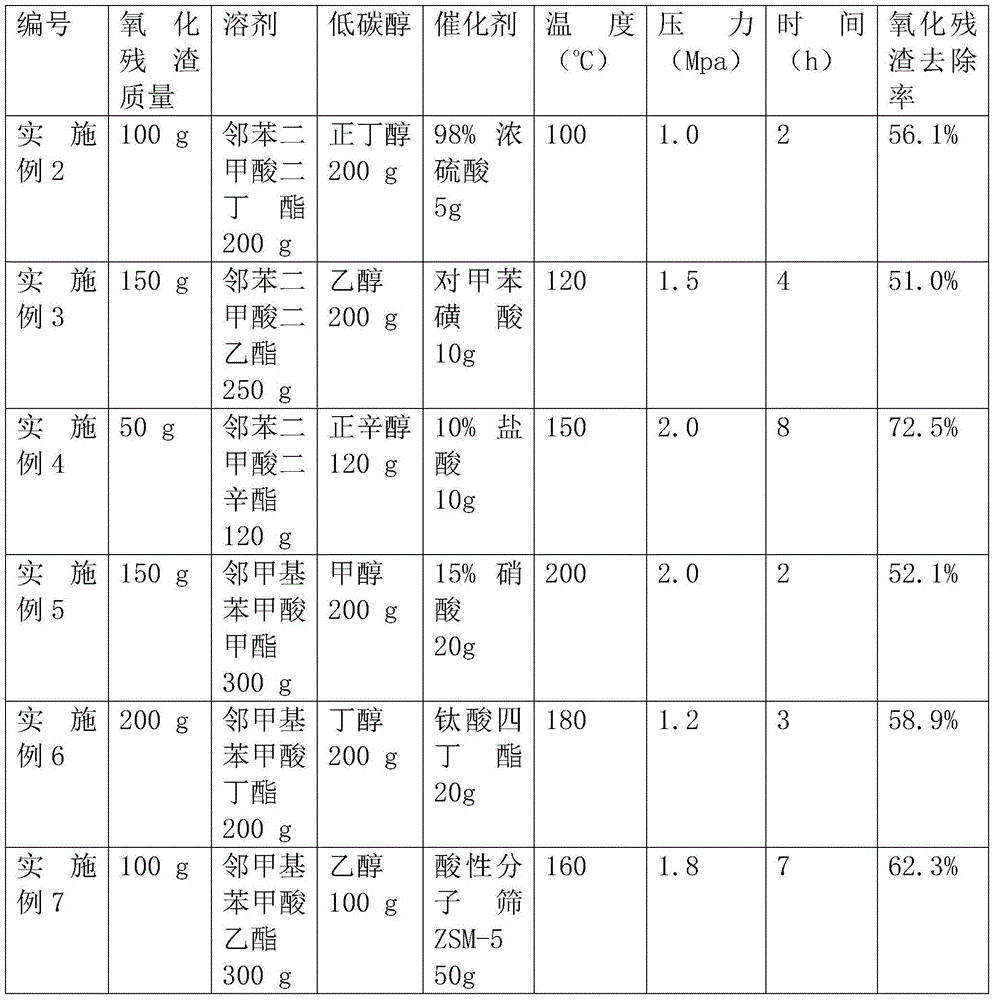

[0022] The reaction process of Example 1 was repeated, except that different solvents, catalysts and reaction conditions were used. The specific raw material reaction conditions and results of each embodiment are listed in Table 1.

[0023] Table 1

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com