Patents

Literature

58 results about "Methylbenzoprim" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

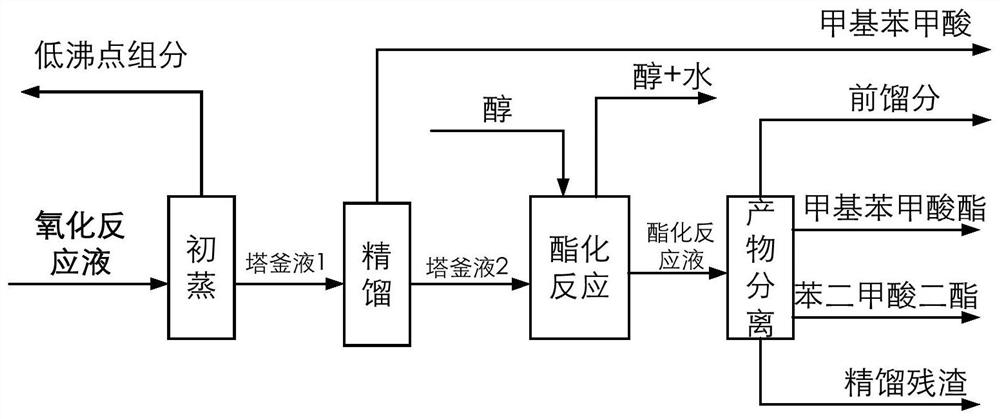

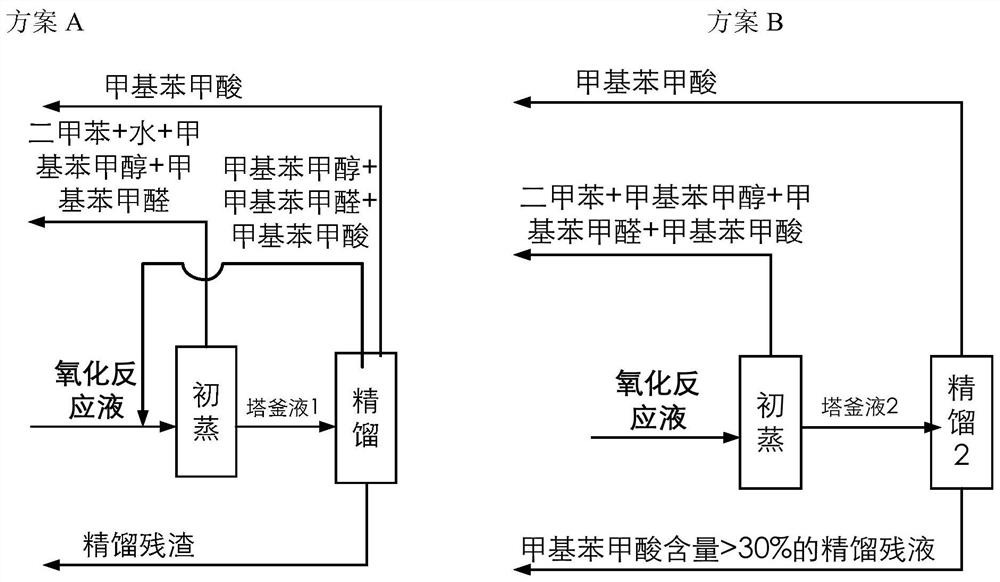

Coproduction method of methylbenzoic acid, methyl benzoate and benzenedicarboxylic acid diester

ActiveCN108047034ARaw materials are easy to getStructural diversificationOrganic compound preparationCarboxylic acid esters preparationAlcoholDistillation

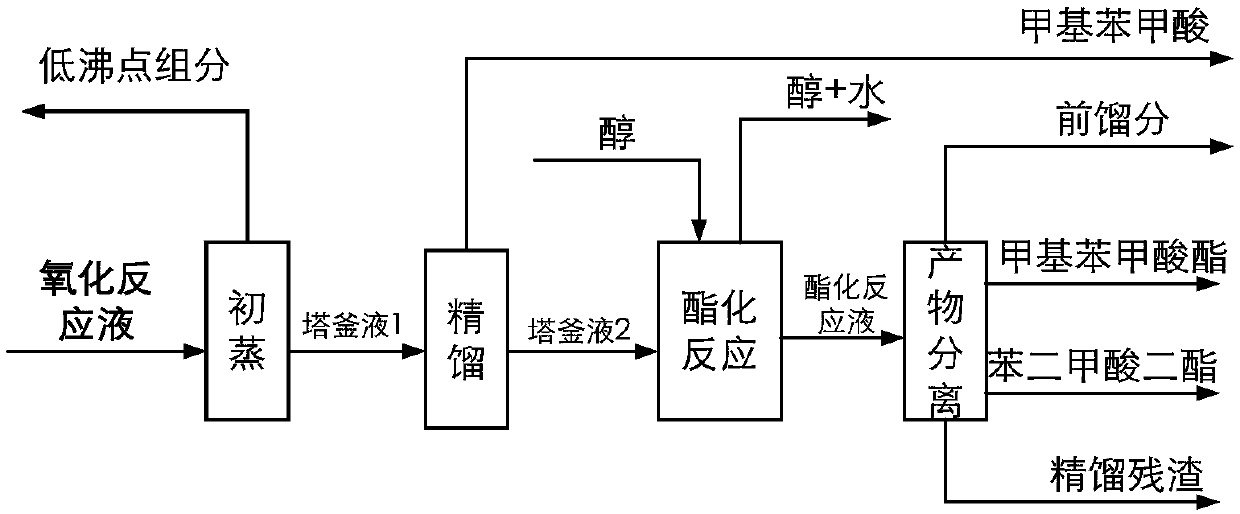

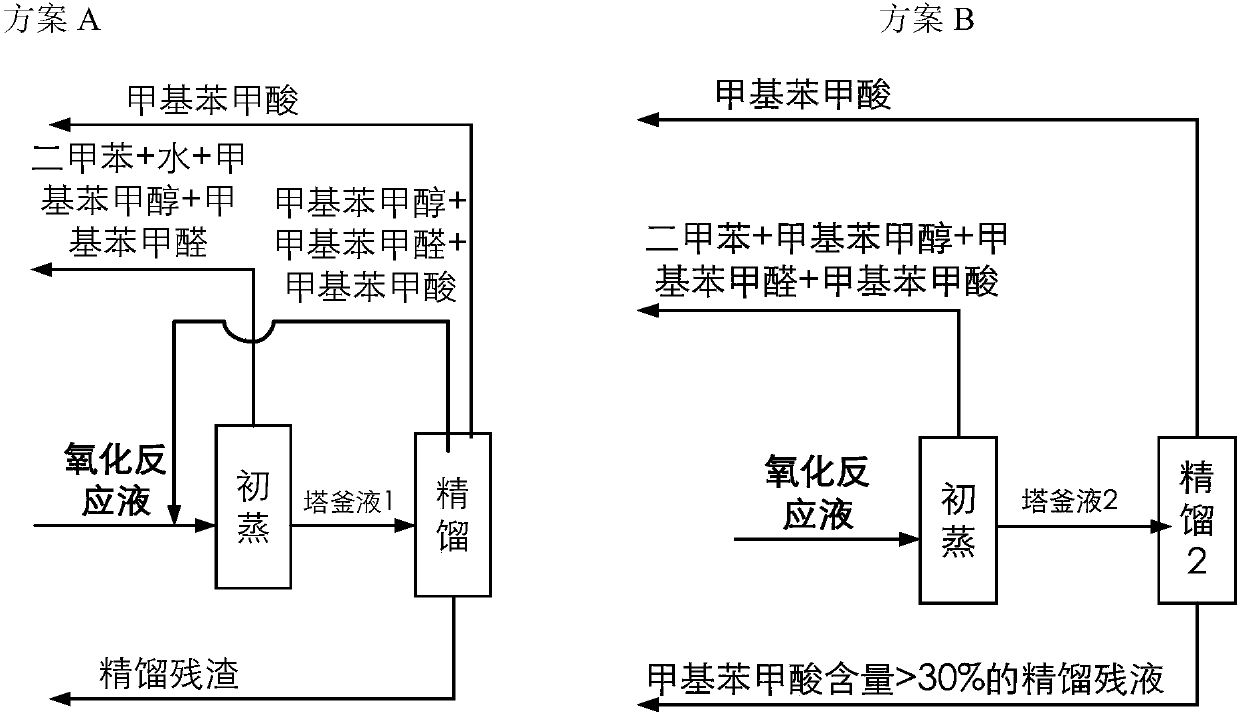

The invention discloses a coproduction method of methylbenzoic acid, methyl benzoate and benzenedicarboxylic acid diester. The method comprises the following steps: (1) continuously introducing xylene, a catalyst and oxygen-containing gas into an oxidation reactor for a reaction, and controlling oxygenic concentration in the tail gas to not exceed 5% by controlling introduction amount of the oxygen-containing gas to obtain an oxidation reaction liquid; (2) feeding the obtained oxidation reaction liquid into a predistillation tower for distillation separation to obtain a low-boiling-point component and a predistillation tower bottom liquid; (3) feeding the predistillation tower bottom liquid into a distillation tower for distillation to obtain a methylbenzoic acid product and a distillationtower bottom liquid; (4) mixing the distillation tower bottom liquid and alcohol for an esterification reaction, and controlling the reaction endpoint to be lower than 0.5wt% of the content of methylbenzoic acid to obtain an esterification reaction liquid; (5) performing distillation separation on the obtained esterification reaction liquid to obtain methyl benzoate and benzenedicarboxylic acid diester products. The method has the advantages that the process is simple, equipment investment is low, and the method is environmentally friendly and has good comprehensive economic benefits.

Owner:JIANGXI KEYUAN BIOPHARM

Abrasion-resistant aluminum alloy doorframe

InactiveCN104563746AHigh mechanical strengthWear-resistantConjugated diene hydrocarbon coatingsWindow/door framesMethylbenzoprimDiethylene glycol

The invention discloses an abrasion-resistant aluminum alloy doorframe. The abrasion-resistant aluminum alloy doorframe comprises an aluminum alloy body and an abrasion-resistant coating which is coated on the surface of the aluminum alloy body, wherein the aluminum alloy is formed by fusing aluminum and chromium at high temperature; the abrasion-resistant coating comprises cis-polybutadiene, a filling agent, a plasticizing agent and a coupling agent; the filling agent is aluminum oxide powder; the plasticizing agent is diethylene glycol binary m-methyl benzoate; the coupling agent is isopropyl titanate tristearate; the percentages by weight of components in the abrasion-resistant coating are as follows: the cis-polybutadiene accounts for 57-77%; the aluminum oxide powder accounts for 17-24%; the diethylene glycol binary m-methyl benzoate accounts for 4-11%; the isopropyl titanate tristearate accounts for 2-8%. The aluminum alloy itself is high in mechanical strength; the surface of the aluminum alloy is protected by the abrasion-resistant coating; the aluminum alloy has the characteristics of sagging resistance, abrasion resistance, impossibility in damage, long service life and good using effect.

Owner:重庆市银泉实业有限公司

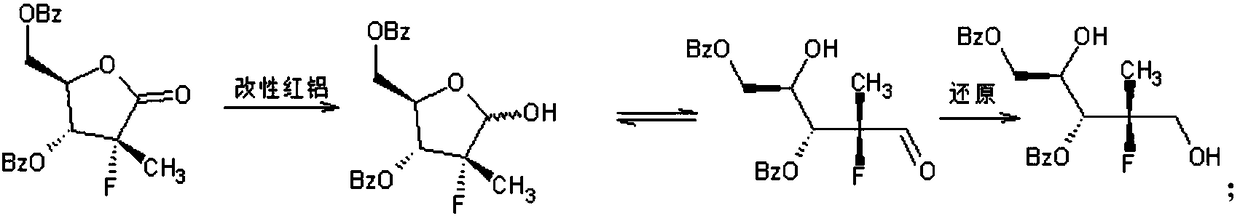

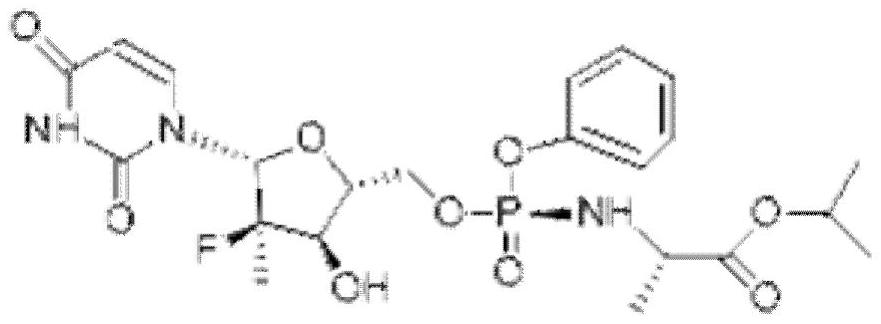

Method for preparing sofosbuvir intermediate and recovering byproduct

ActiveCN107245064AReduce security risksReduce energy consumptionEther preparationRefluxMethylbenzoprim

The invention relates to a method for preparing a sofosbuvir intermediate [(2R,3R,4R)-3-(benzoyloxy)-4-fluoro-5-hydroxy-4-methyltetrahydrofuran-2-yl] methylbenzoate represented by formula (II) and recovering a byproduct (2R,3R,4S)-4-fluoro-2,5-dihydroxy-4-methylpentane-1,3-diyl]dibenzoate represented by formula (III). The method comprises the following steps: (1) reacting a compound (I) 3,5-dibenzoyl-2-deoxy-2-fluoro-2-methyl-D-ribosinic acid-gamma-lactone in a first solvent under the action of a reducing agent at a temperature of from 0 DEG C to the reflux temperature of the first solvent for 1-20 hours to produce the sofosbuvir intermediate (II) and the byproduct (III); and (2) filtering the above product to obtain a filter cake which is the byproduct (III), dissolving the filter cake in a second solvent, and reacting the obtained solution in an acidic environment with the pH value of 1-6 under the action of an oxidant and a catalyst at a temperature from 0 DEG C to the reflux temperature of the second solvent for 0.5-5 hours in order to generate the compound (I).

Owner:NINGBO TEAM PHARMA

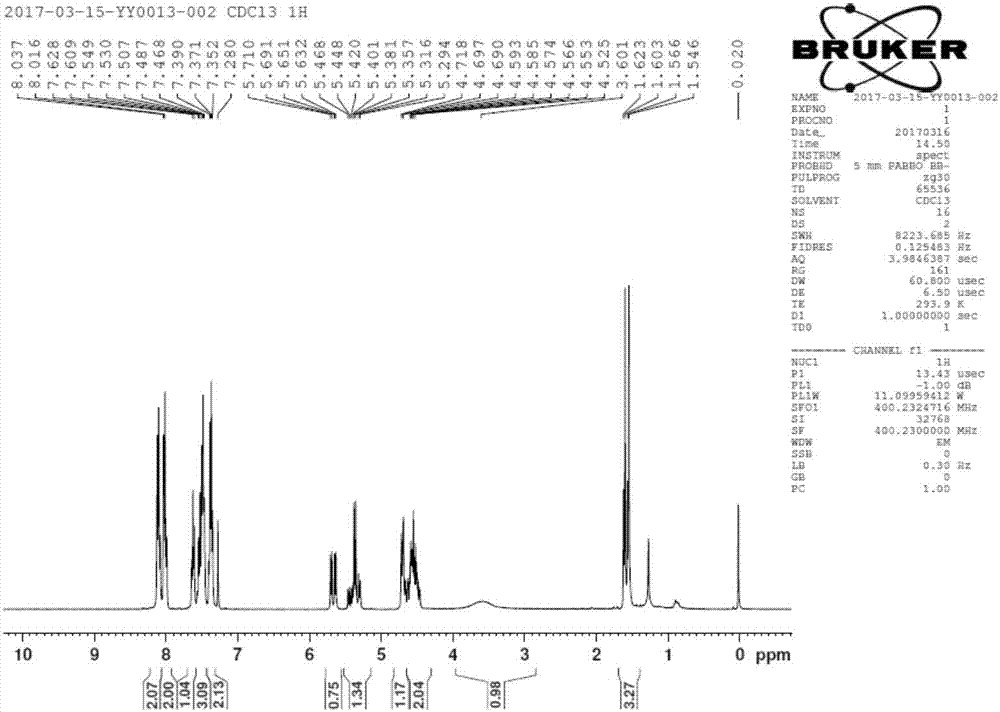

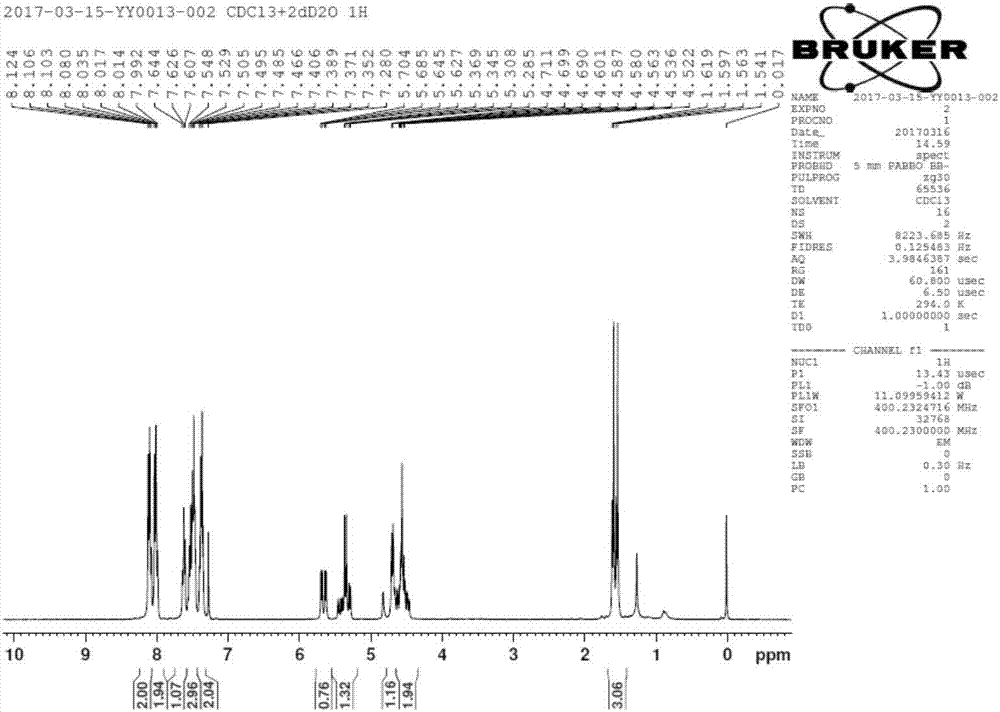

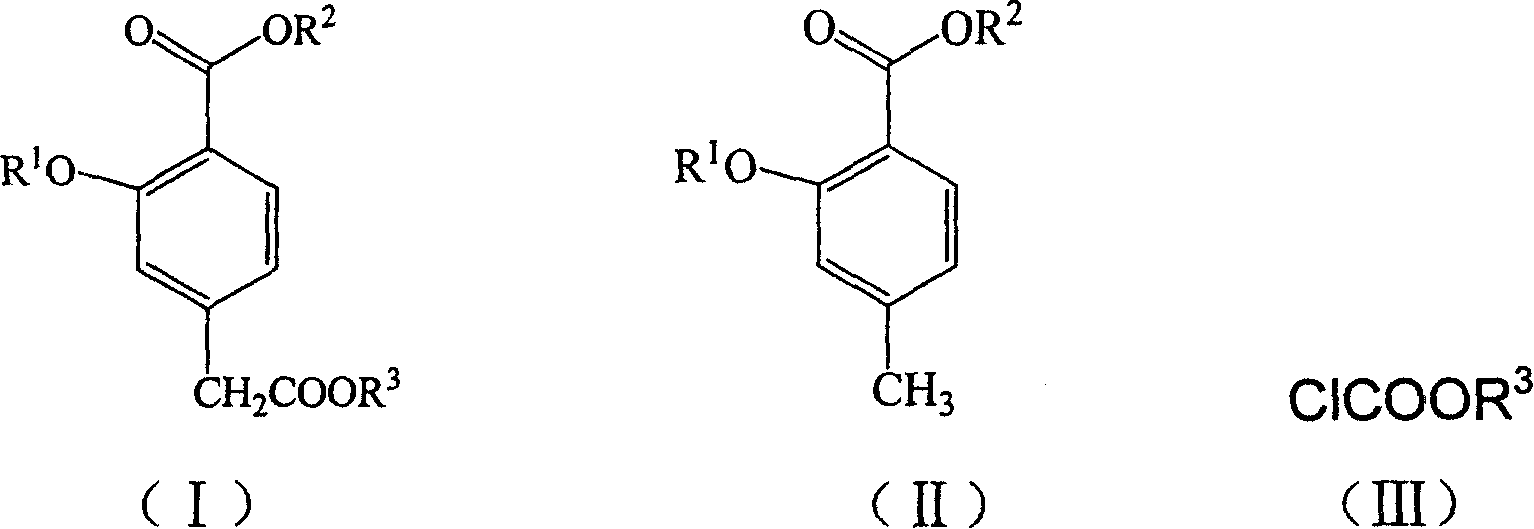

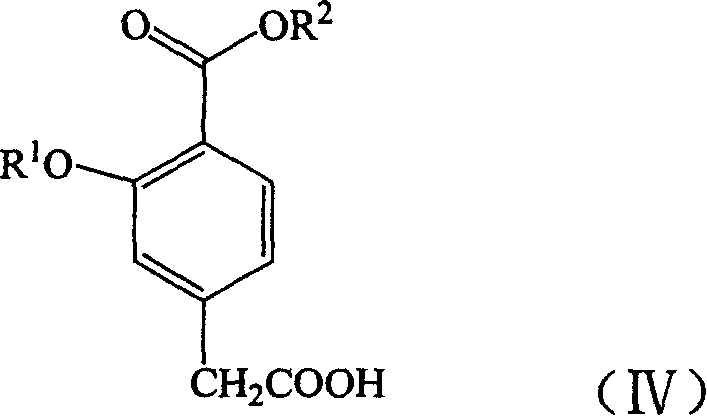

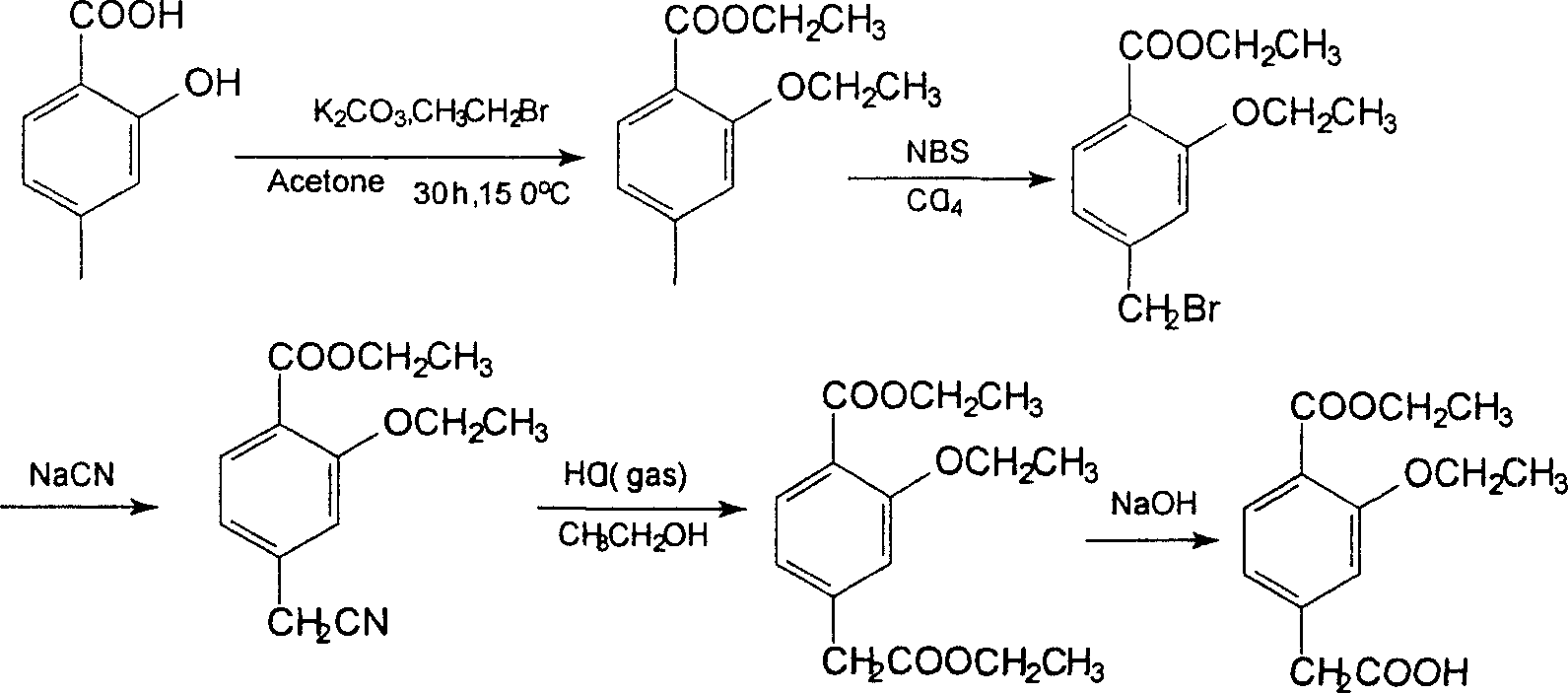

3- alkoxy -4-carbalkoxyphenylacetate and 3-alkoxy-4-carbalkoxyphenylacetic acid synthesis method

ActiveCN1800139ACheap manufacturingSafe preparationOrganic compound preparationCarboxylic acid esters preparationEthyl phenylacetateOrganic solvent

The invention provides a method for synthesizing 3-alkoxy-4-alkoxycarbonyl phenylacetate and 3-alkoxy-4-alkoxycarbonyl phenylacetic acid. The method for synthesizing 3-alkoxy-4-alkoxycarbonyl phenylacetate comprises: 3-alkoxy-4-methyl benzoate reacts with the chloro-carbonate on the effect of strong base in the organic solution at 190 deg.-0 deg. to obtain the product; the method of the 3-alkoxy-4-alkoxycarbonyl acetic ether cheesed hydrolysis to obtain the 3-alkoxy-4-alkoxycarbonyl phenylacetic acid.

Owner:ZHEJIANG HISOAR CHUANNAN PHARMA

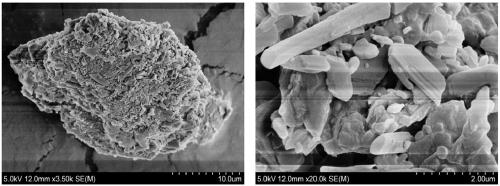

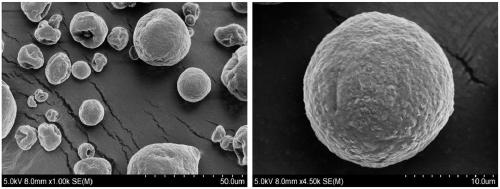

Synthesis method of bagasse xylan o-methylbenzoate-g-AM (Acrylamide)/MMA (Methyl Methacrylate)

InactiveCN109400759AGood water solubilityIncrease profitAntineoplastic agentsSolubilitySynthesis methods

The invention discloses a synthesis method of bagasse xylan o-methylbenzoate-g-AM (Acrylamide) / MMA (Methyl Methacrylate). The synthesis method takes natural macromolecular bioactive bagasse xylan as amain raw material, acrylamide (AM) and methyl methacrylate (MMA) as a mixed grafting monomer, and ammonium persulfate and sodium hydrogensulfite as an initiation system to synthesize bagasse xylan-g-AM / MMA; then 4-dimethylaminopyridine is used as a catalyst and o-methylbenzoic acid is used as an esterification agent; the catalyst and, esterification agent and a grafting copolymer bagasse xylan-g-AM / MMA are subjected to catalystic esterification reaction in an N,N-dimethylacetylamide (DMA) solvent to synthesize a final product bagasse xylan syringateo-methylbenzoate-g-AM / MMA. According to thesynthesis method disclosed by the invention, three types of anti-bioactivity groups are introduced through esterification, grafting and crosslinking compound modification of the bagasse xylan, so thatthe activity including water solubility, cancer resistance and, bacterium resistance and the like of original bagasse xylan is enhanced; the bagasse xylan o-methylbenzoate-g-AM / MMA has relatively high application value in the fields including medicines and, foods and the like.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

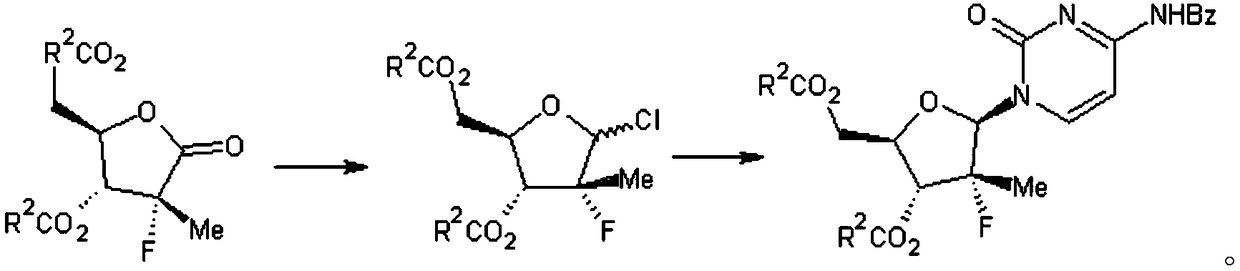

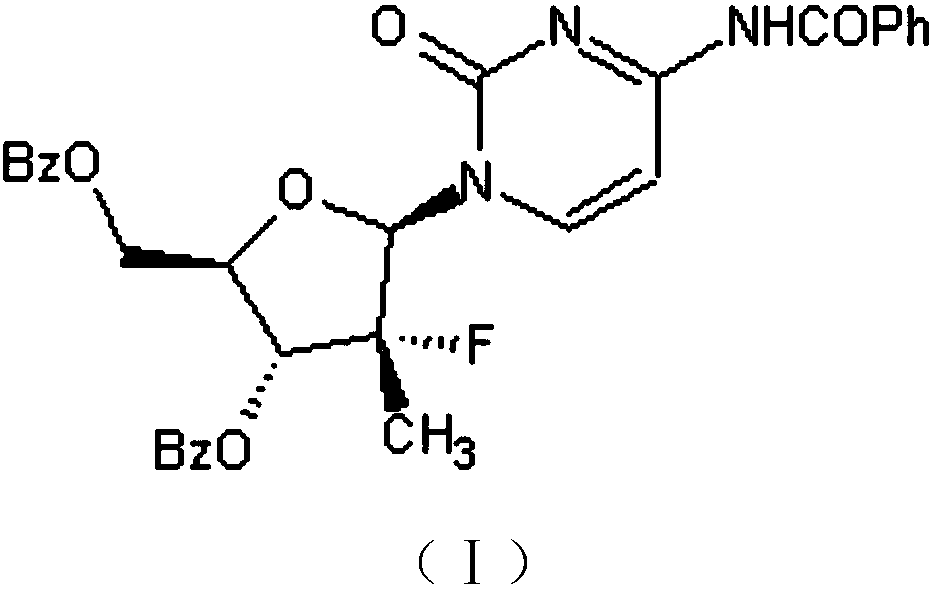

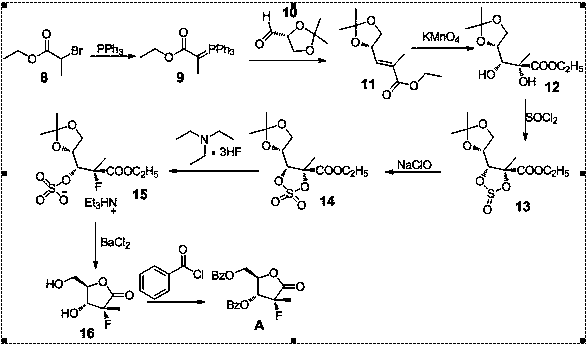

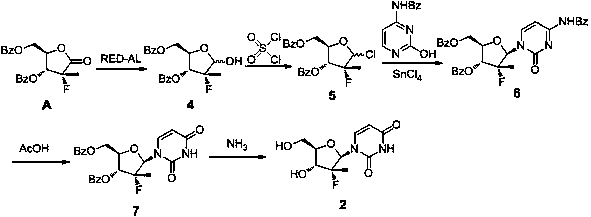

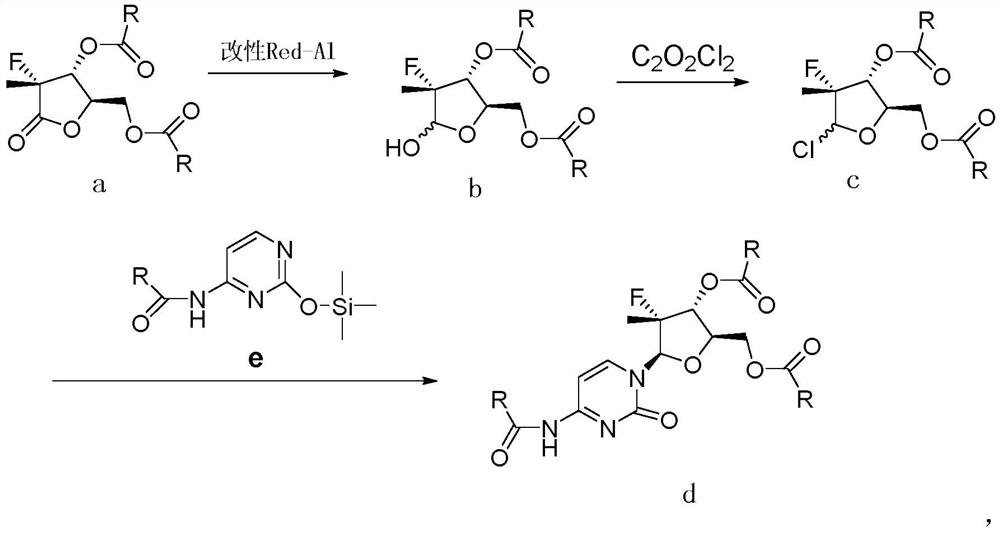

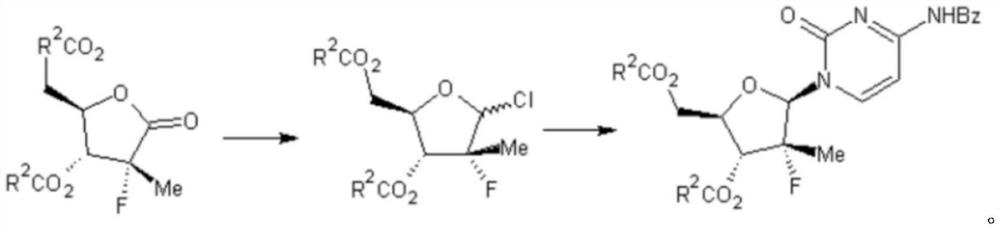

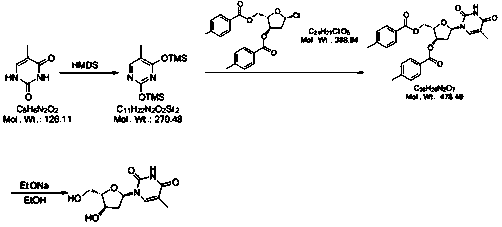

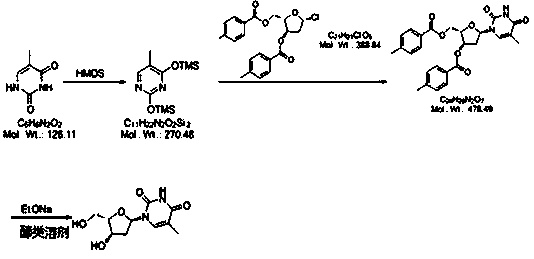

Synthesis method of key sofosbuvir intermediate

PendingCN109438537AGood choiceLow priceSugar derivativesSugar derivatives preparationCytosineTrimethylsilyl

The invention relates to a synthesis method of a key sofosbuvir intermediate shown as a formula (I). The synthesis method comprises the following steps: with a compound 3,5-dibenzoyl-2-deoxy-2-fluoro-2methyl-D-ribose-gamma-lactone as a raw material, selectively reducing by using modified passivated red aluminum to produce a compound [(2R,3R,4R)-3-(benzoyloxy)-4-fluoro-5-hydroxy-4-methyltetrahydrofuran-2-yl] methyl benzoate, chlorinating the compound [(2R,3R,4R)-3-(benzoyloxy)-4-fluoro-5-hydroxy-4-methyltetrahydrofuran-2-yl] methyl benzoate, performing condensation on the compound [(2R,3R,4R)-3-(benzoyloxy)-4-fluoro-5-hydroxy-4-methyltetrahydrofuran-2-yl] methyl benzoate and N-benzoyl-O-(trimethylsilyl)cytosine to produce the sofosbuvir intermediate (2'R)-N-benzoyl-2'-deoxy-2'-fluoro-2'-methylcytidine-3',5'-dibenzoate. By the synthesis method, the compound [(2R,3R,4R)-3-(benzoyloxy)-4-fluoro-5-hydroxy-4-methyltetrahydrofuran-2-yl] methyl benzoate is highly selectively prepared by replacing commonly used trifluoroethanol with a passivating agent morpholine; in the reaction process, byproducts are reduced, so that progression of a subsequent reaction is facilitated; and the synthesismethod has a huge industrial production prospect.

Owner:JIANGSU COBEN PHARMA CO LTD

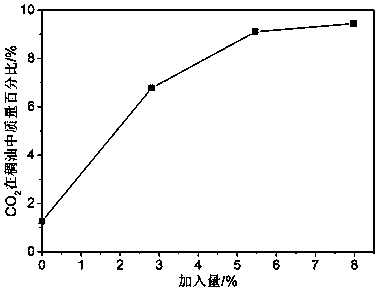

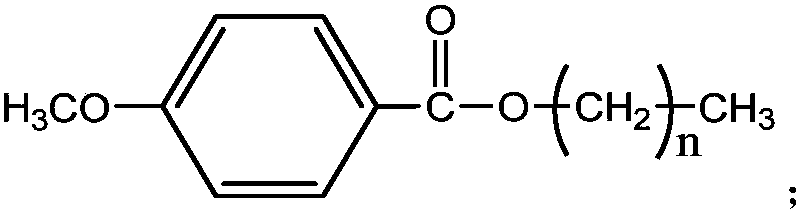

Oil displacement additive for enhancing intersolubility of CO2 with crude oil and reducing viscosity of crude oil

ActiveCN107828401AEnhanced ability to dissolve in crude oilImprove liquidityDrilling compositionOil additiveMethylbenzoprim

The invention discloses an oil displacement additive for enhancing the intersolubility of CO2 with crude oil and reducing the viscosity of the crude oil. The oil displacement additive consists of a solubilizer and an oil-soluble viscosity reducer, and the weight ratio of the solubilizer to the oil-soluble viscosity reducer is (2-8):1, wherein the solubilizer is a p-methyl benzoate compound and theoil-soluble viscosity reducer is a long-chain acrylic ester-vinyl acetate-acrylamide copolymer. The oil displacement additive provided by the invention can be mutually dissolved with a CO2 fluid; through the change of the thermodynamic property of the CO2 fluid, the ability of CO2 of dissolving into crude oil is enhanced, so that mixed-phase displacement can be promoted. In addition, the oil displacing agent can be further carried by CO2 to the contact part with the crude oil, and is dissolved in the crude oil, so that the micellar structure formed by stacking and accumulation of asphaltene-colloid in the crude oil is destroyed, a viscosity reduction effect is achieved, and the fluidity of crude oil is enhanced. The oil displacement additive is especially suitable for high-viscosity and low-permeability heavy oil reservoirs and has a wide application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

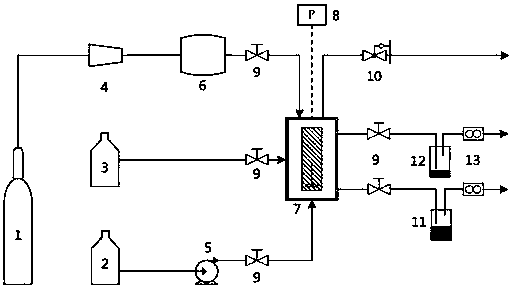

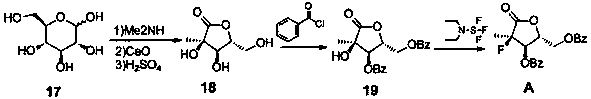

Preparation method for sofosbuvir fluorofuran intermediate

ActiveCN109422710ASimple processNon-hazardous workmanshipOrganic chemistryMethylbenzoprimCombinatorial chemistry

The invention provides a preparation method for a sofosbuvir fluorofuran intermediate. The invention provides the preparation method for an important sofosbuvir intermediate, namely, ((2R,3R,4R)-3-(benzoyloxy)-4-fluoro-4-methyl-5-oxytetrahydrofuran-2-yl)methylbenzoate (a fluorofuran fragment, with a structural formula A which is described in the specification).

Owner:CHANGZHOU PHARMA FACTORY

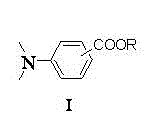

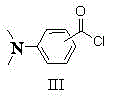

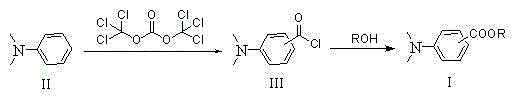

Preparation method of N,N-dimethyl benzoate composite

ActiveCN105367436AThe reaction conditions are mild and easy to controlReduce riskOrganic compound preparationAmino-carboxyl compound preparationDimethylaniline N-oxideAlcohol

The invention relates to a preparation method of an N,N-dimethyl benzoate composite, in particular to a preparation method for preparing N,N-dimethyl benzoate by using N,N-dimethylaniline, bi(trichloromethyl)carbonic ester and alcohol as raw materials. The raw materials are cheap and easy to obtain, the yield is high, a midbody does not need to be purified, a continuous reaction can be performed without replacing solvents, the preparation method is cheap, environmentally friendly, easy to implement and suitable for industrialization, and the method can be used for preparing the important chemical and medical midbody through N,N-dimethyl benzoyl chloride.

Owner:TIANJIN JIURI NEW MATERIALS CO LTD

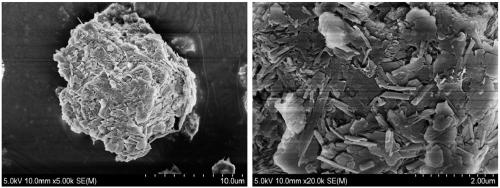

Synthetic method of active bagasse xylan o-toluic acid esterification-g-AM

InactiveCN109400757AGood biocompatibilityImprove biological activityAntibacterial agentsAntineoplastic agentsSolubilityCross-link

The invention discloses a synthetic method of active bagasse xylan o-toluic acid esterification-g-AM. The synthetic method adopts natural macromolecular biological active bagasse xylan as a main raw material, adopts ammonium persulfate and sodium hydrogen sulfite as an initiation system, adopts N,N'-methylene bisacrylamide as a cross-linking agent to prepare bagasse xylan-g-AM; and then the synthetic method adopts the bagasse xylan-g-AM as a raw material, adopts o-toluic acid as an esterification agent, and adopts toluenesulfonic acid as a catalyst to prepare the bagasse xylan o-toluic acid esterification-g-AM in the N,N-dimethylacetamide (DMA) solvent. A product prepared in the synthetic method of the invention performs the esterification reaction on the basis of grafting, and a final synthesized product of bagasse xylan o-toluic acid esterification-g-AM not only solves the problem that the bagasse xylan is poor in solubility and enlarges the application range, but also further improves the biological activity of the bagasse xylan by introducing the active groups of acrylamide (AM) and o-toluic acid.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

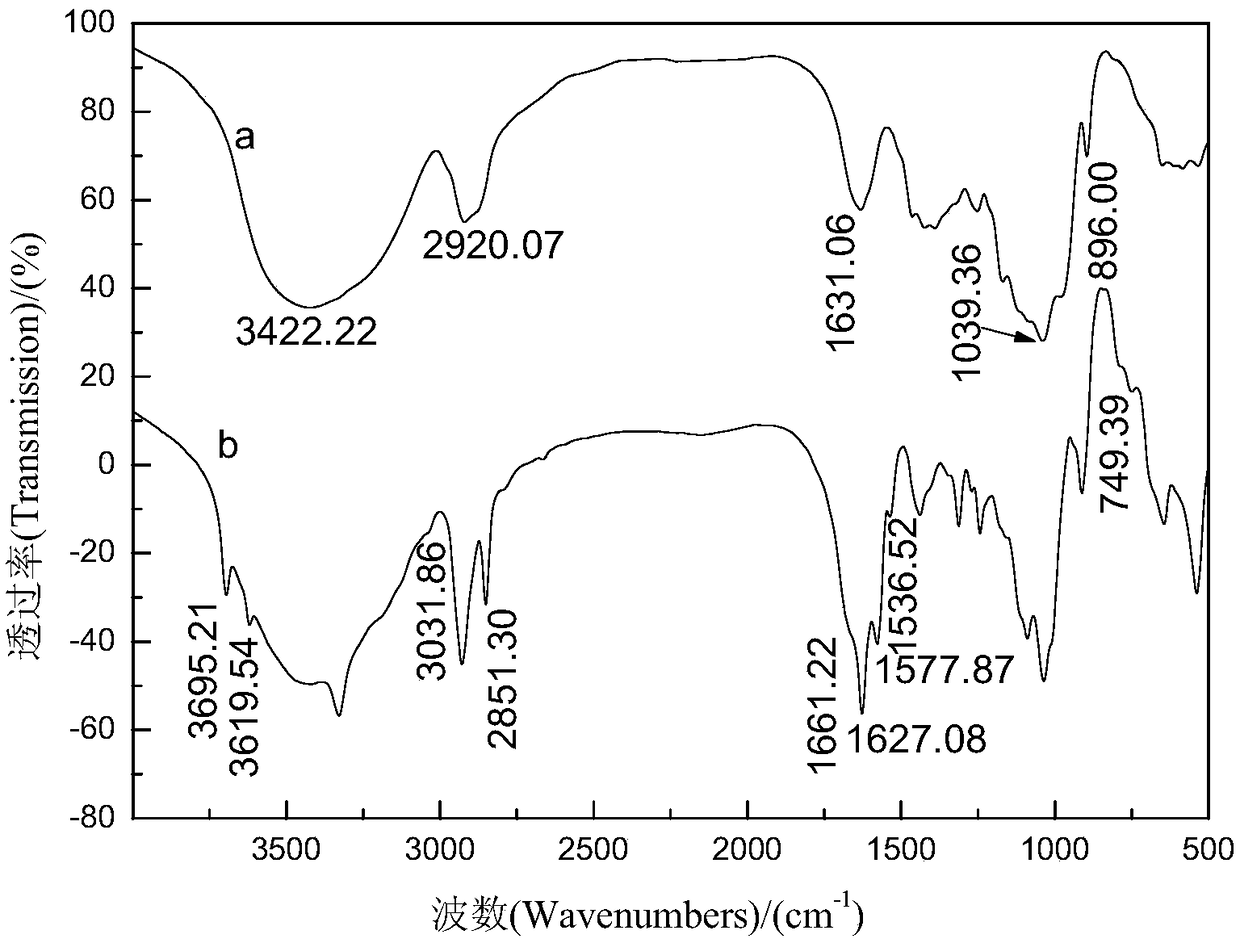

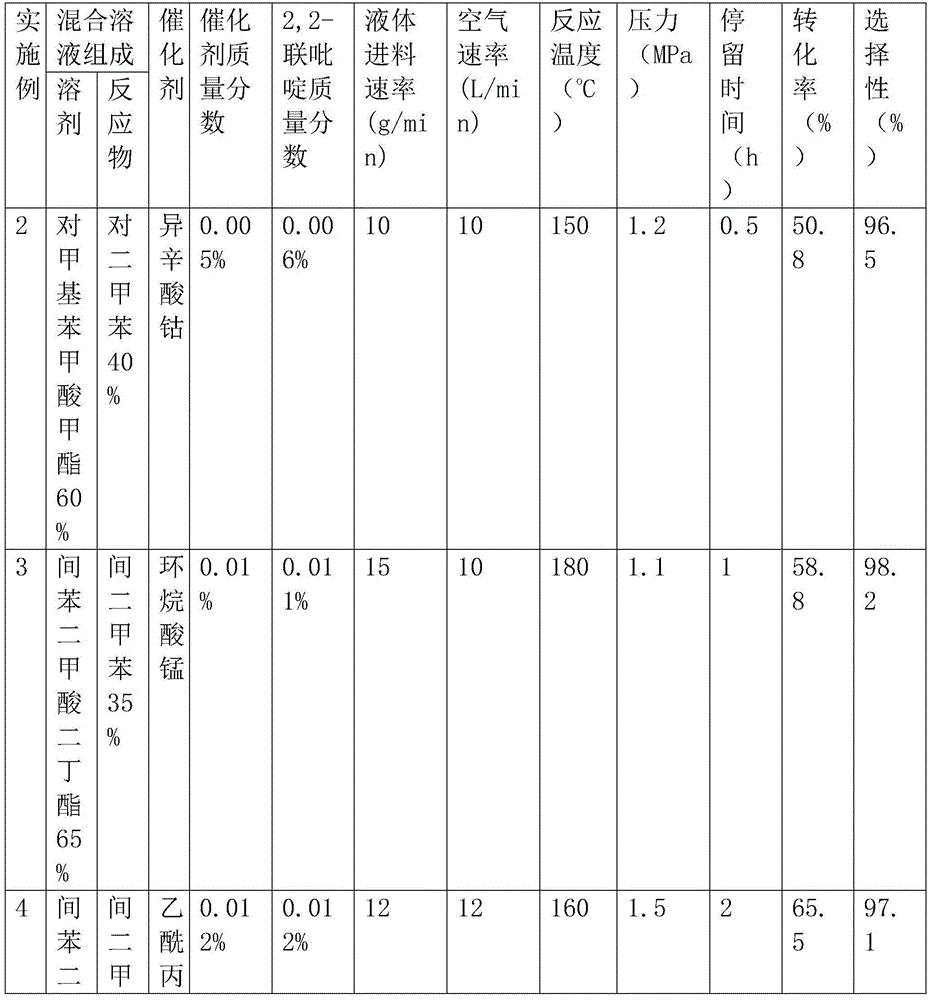

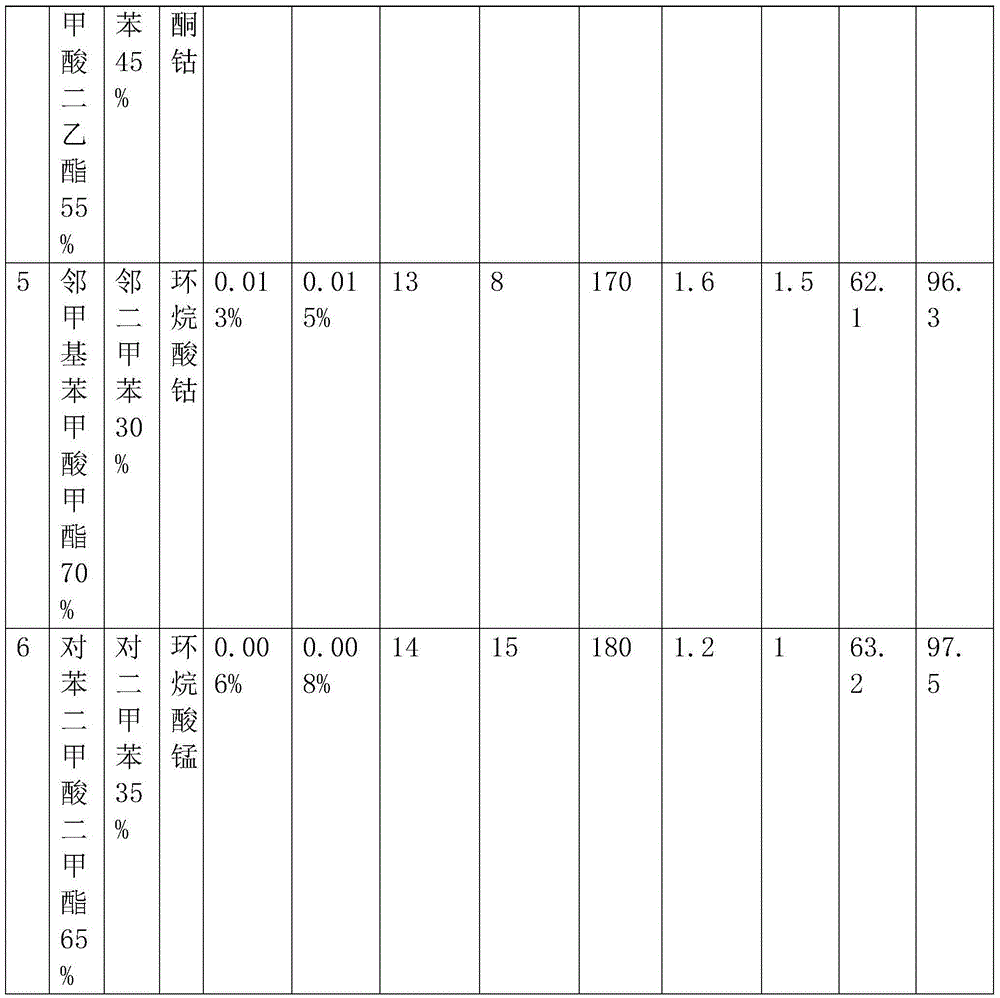

Method for preparing phthalic acid through liquid phase catalytic oxidation of xylene

ActiveCN106187750AReduce dosageNot easily deactivated by complexationOrganic compound preparationCarboxylic compound preparationReaction temperatureCatalytic oxidation

The invention discloses a method for preparing phthalic acid through liquid phase catalytic oxidation of xylene, wherein the method is suitable for liquid phase oxidation reactions of p-xylene, o-xylene and m-xylene. Specifically the method comprises that phthalic acid ester or methyl benzoate is adopted as a solvent, air or oxygen is adopted as an oxidant, oil-soluble Co or Mn is adopted as a catalyst, 2,2-bipyridine and other complexing agents are adopted as additives, and oxidation is performed to obtain the phthalic acid, wherein the reaction temperature is 150-240 DEG C, and the reaction pressure is 0.5-2.0 Mpa. According to the present invention, the technology has the good universality and is suitable for the oxidation of p-xylene, o-xylene and m-xylene, the consumption of the catalyst in the method is less, the catalyst is not easily subjected to complexation inactivation, the concentration fluctuation range of the catalyst during the reaction process is small, the running period is long, the reaction effect is good, the flexible adjusting according to different reaction characteristics can be achieved, and other advantages are provided.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

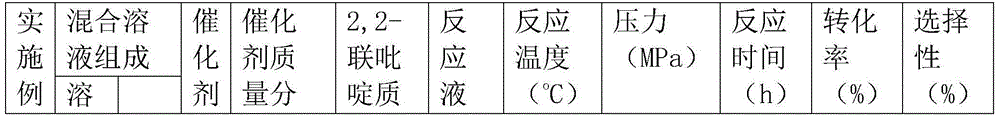

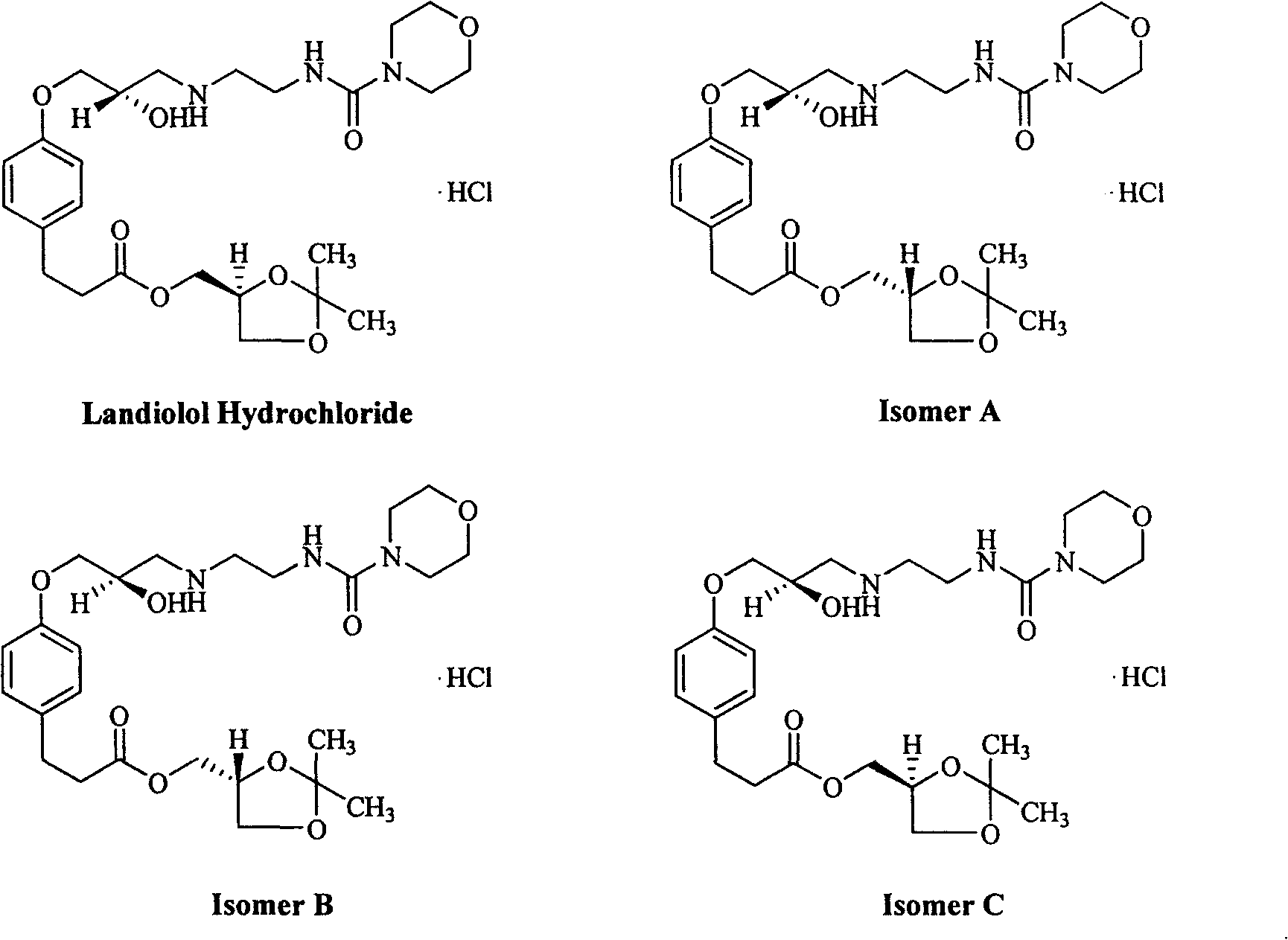

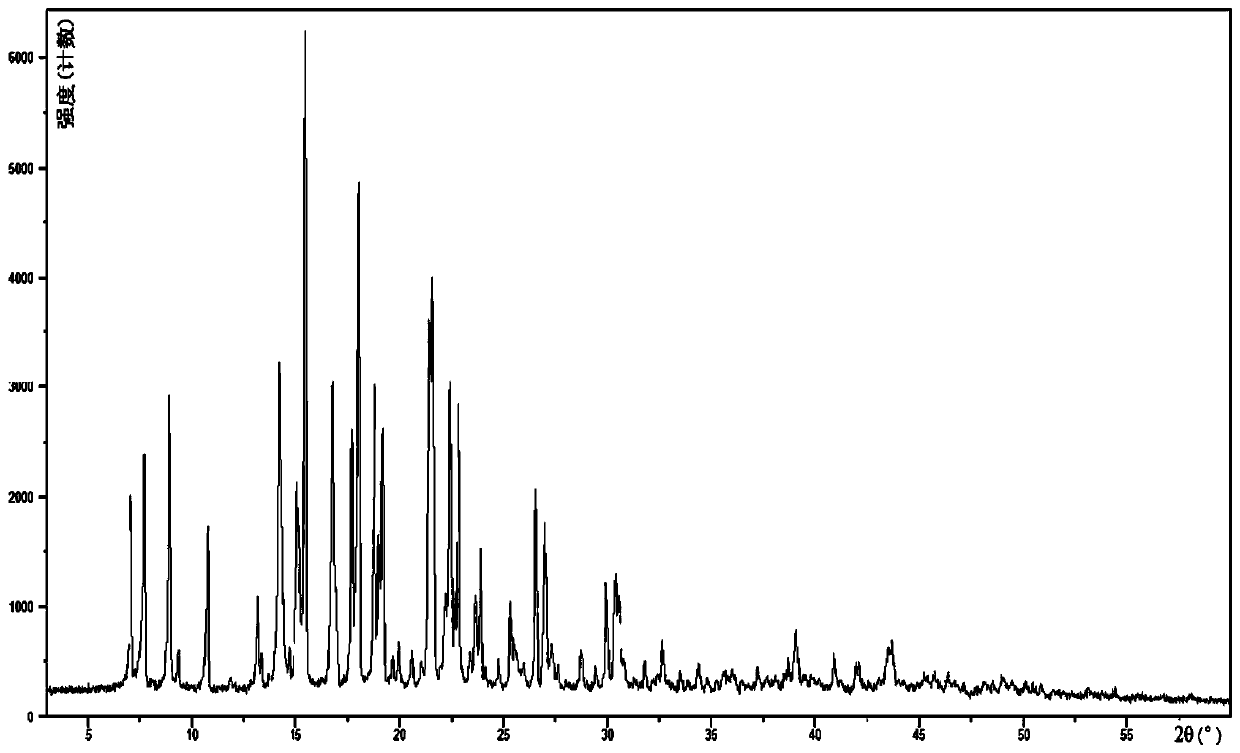

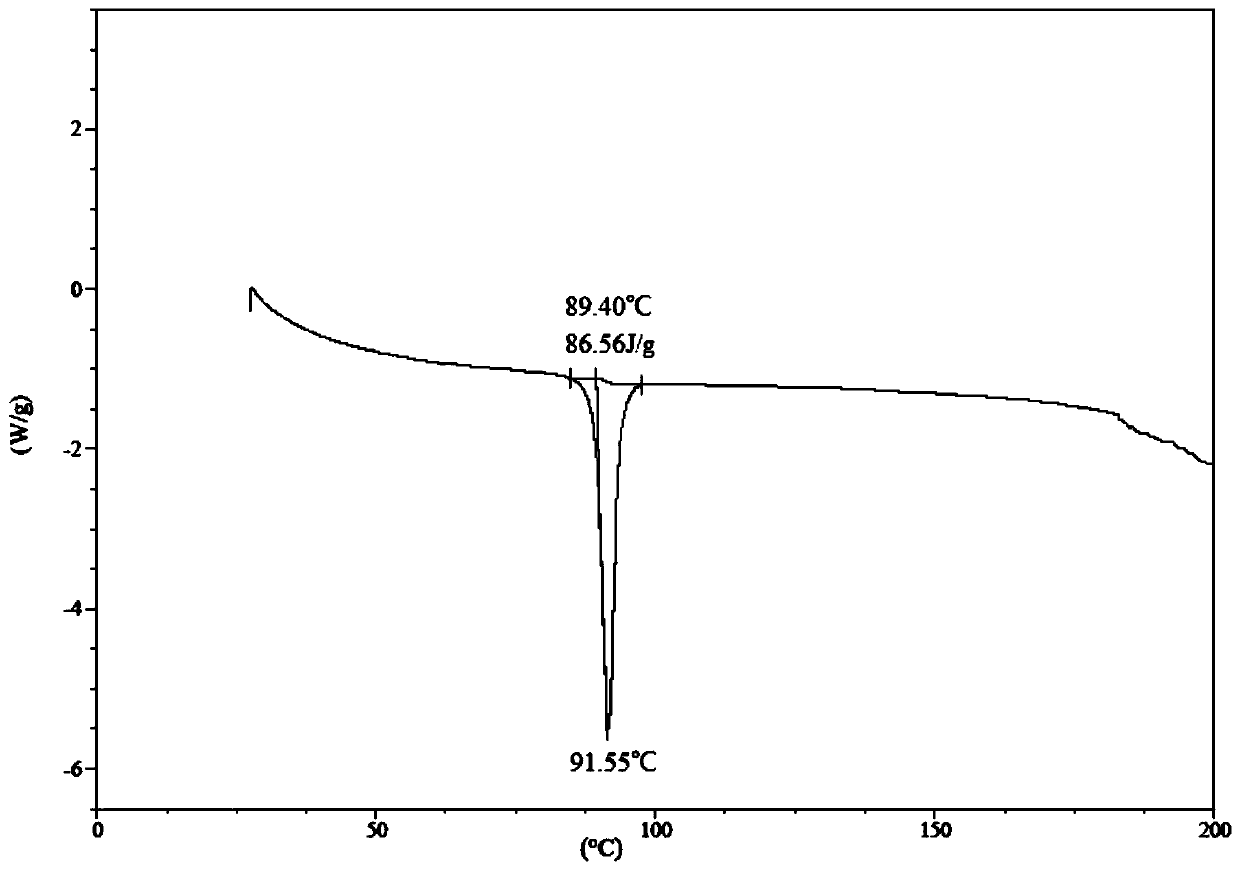

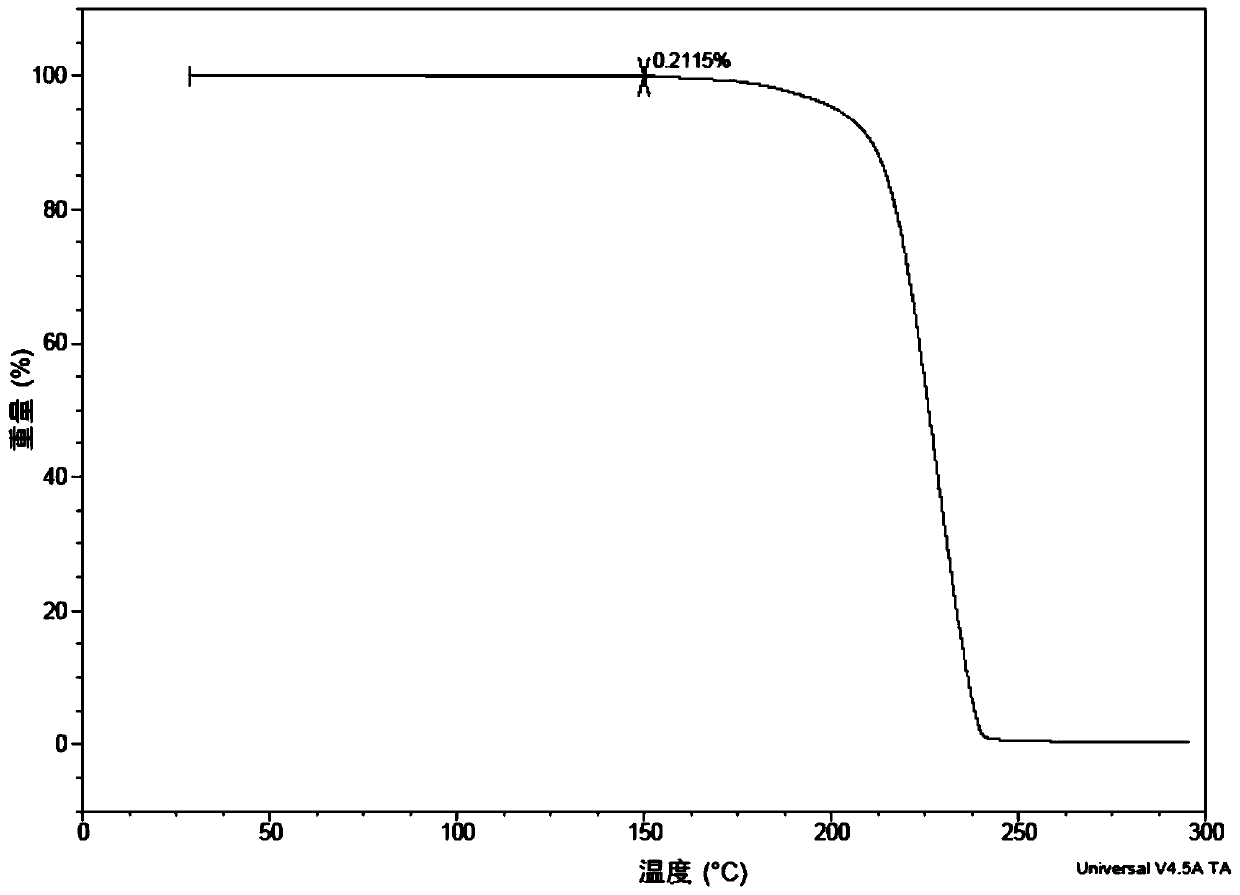

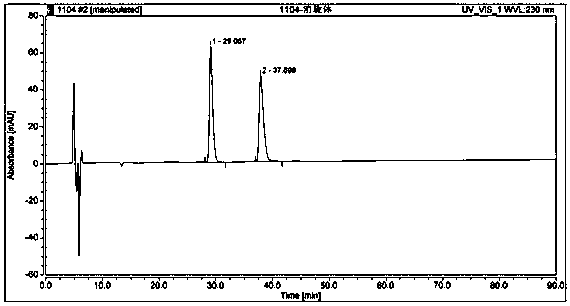

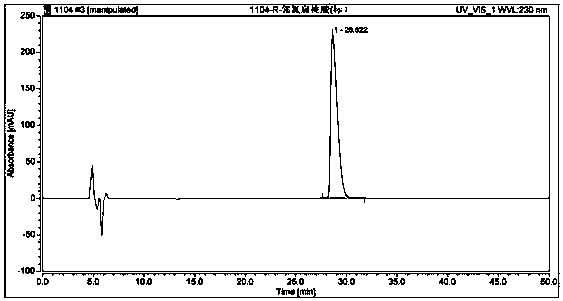

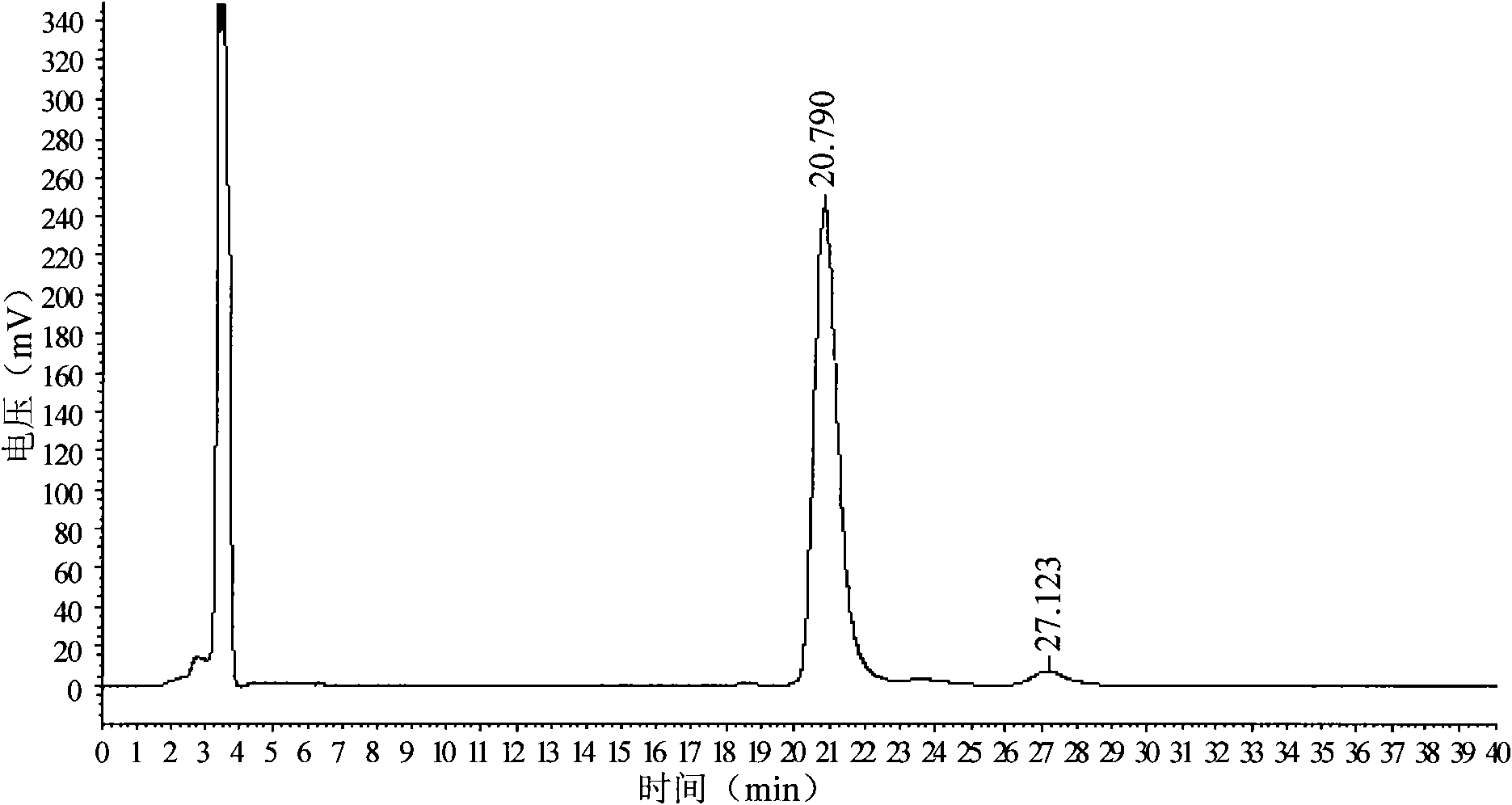

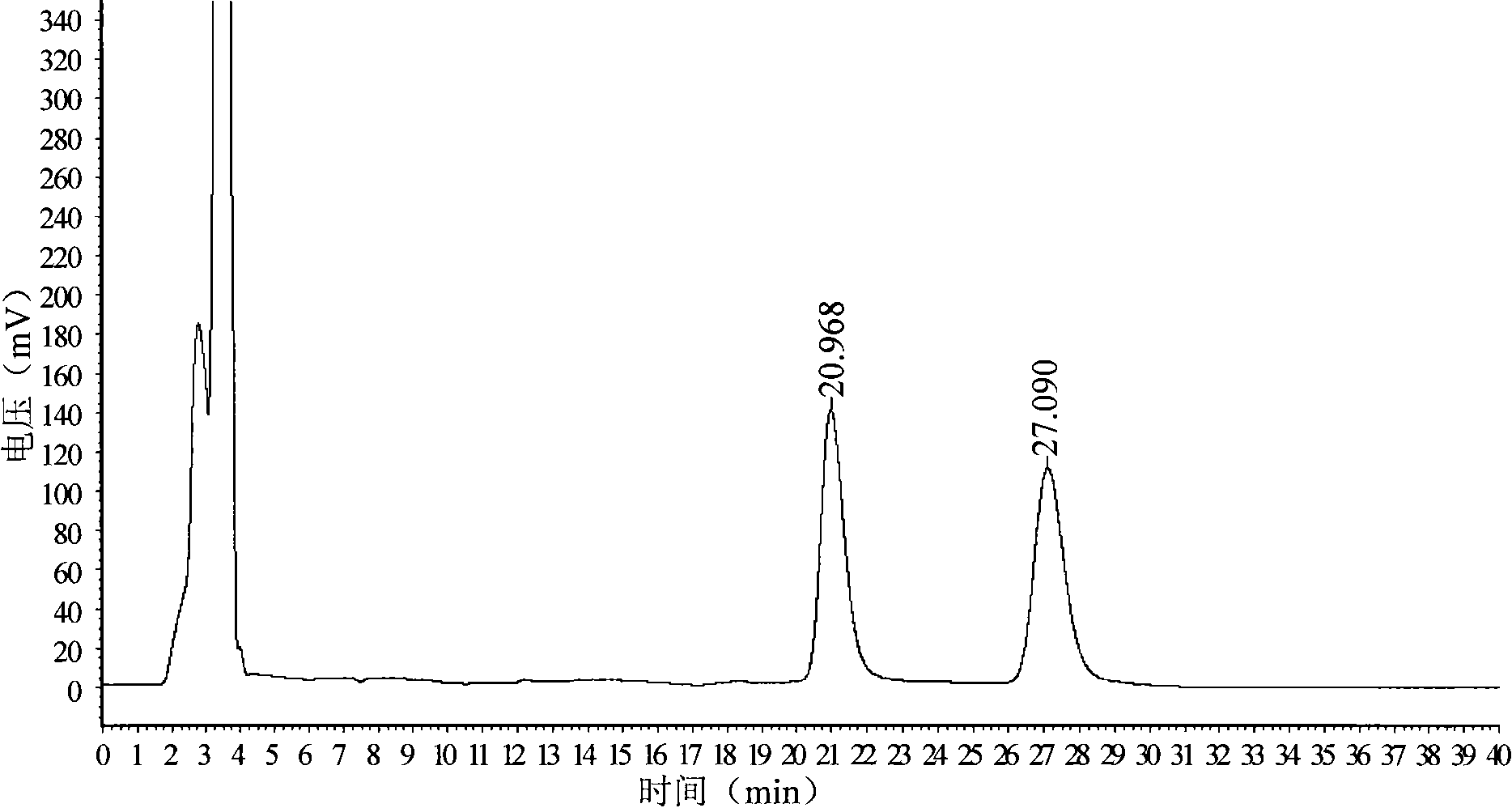

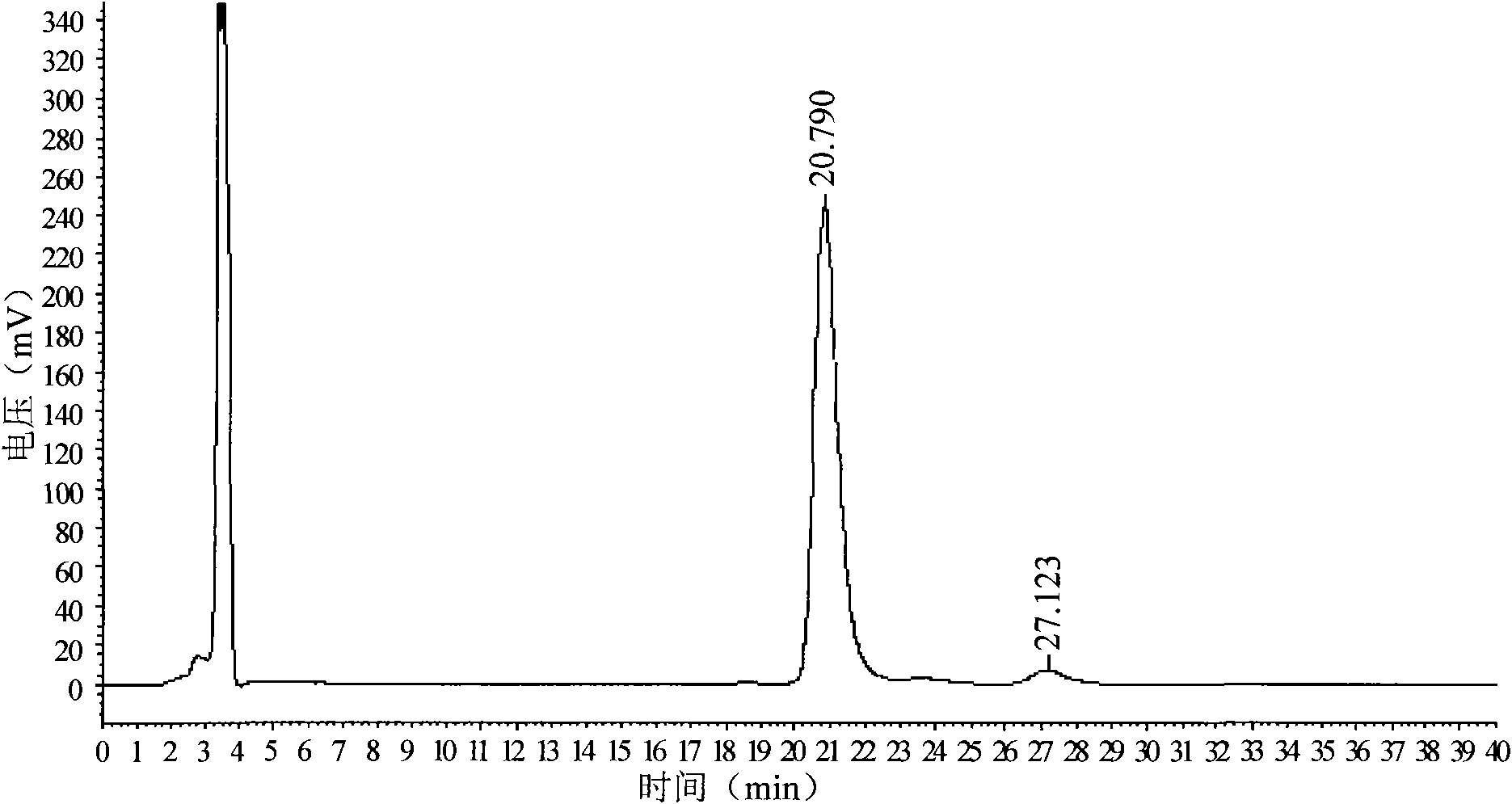

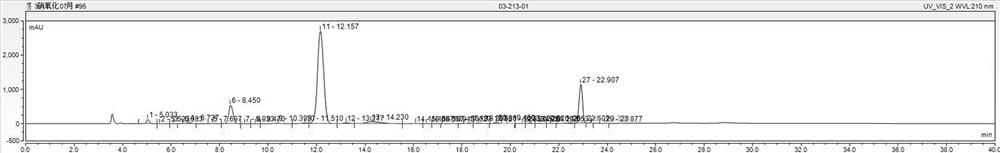

Method for detecting landiolol hydrochloride optical isomers by high efficiency liquid chromatography

The invention provides a method for detecting landiolol hydrochloride optical isomers by a high efficiency liquid chromatography, comprising the following steps: (1) configuring chromatographic conditions: a chromatographic column adopting silica gel the surface of which is coated with cellulose tris(4-methylbenzoate) is a fixed phase chiral column; a mobile phase is normal hexane-isopropanol-diethylamine; and the detection wave length is 200nm-240nm; (2) adopting organic solvent to prepare a sample into solution containing 0.5-5.0mg / ml of landiolol hydrochloride; and (3) determining and recording chromatogram. The separating degrees of landiolol hydrochloride and landiolol hydrochloride isomers A, B, C reached by the determination method of the invention can reach 1.5-3.9, which conforms to the requirement of Chinese pharmacopoeia. The method provided by the invention can be used for quantifying the landiolol hydrochloride optical isomers.

Owner:南京海辰药业股份有限公司

Aluminum alloy door frame

InactiveCN107035271AHigh strengthImprove mechanical propertiesMolten spray coatingWindow/door framesManganeseMethylbenzoprim

The invention provides an aluminum alloy door frame. The aluminum alloy door frame comprises an aluminum alloy base material and a functional coating with which the surface of the aluminum alloy base material is coated. The aluminum alloy base material is prepared from, by weight, 5-8 parts of silicon, 6-10 parts of nickel, 5-8 parts of chromium, 1-2 parts of copper, 0.5-1 part of iron, 1-2 parts of manganese, 1-2 parts of magnesium, 1-2 parts of zinc, 0.5-1 part of titanium, smaller than or equal to 200 ppm of calcium, 0-0.2 part of lead, 0-0.05 part of cadmium and the balance aluminum. The functional coating is prepared from 20-50 parts of butadiene rubber, 20-50 parts of filler, 8-10 parts of plasticize and 3-10 parts of coupling agent. The filler is prepared from, by mass, 30-60% of aluminum oxide-titanium dioxide composite, 20-40% of manganese dioxide and 10-40% of silicon dioxide. The lubricating agent is organic silicon oil, the coupling agent is isopropyl trioleate trioleate, and the plasticizer is diethylene glycol dimethyl benzoate. The aluminum alloy door frame is high in surface strength, good in corrosion resistance and scraping resistance and attractive in appearance.

Owner:合肥市旺友门窗有限公司

Solid forms of adamantyl compound, compositions and uses thereof

Provided herein are crystalline forms of ( ( ( ( (1r, 3R, 5S, 7r) -3, 5-dimethyladamantan-1-yl)carbamoyl) oxy) methyl benzoate (Compound (I)): Also provided are compositions comprising the crystallineforms of Compound (I), processes of manufacture and methods of using the crystalline forms of Compound (I).

Owner:SUNSHINE LAKE PHARM CO LTD

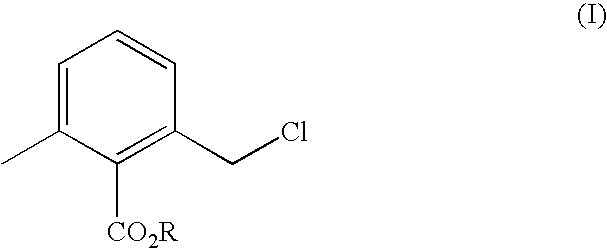

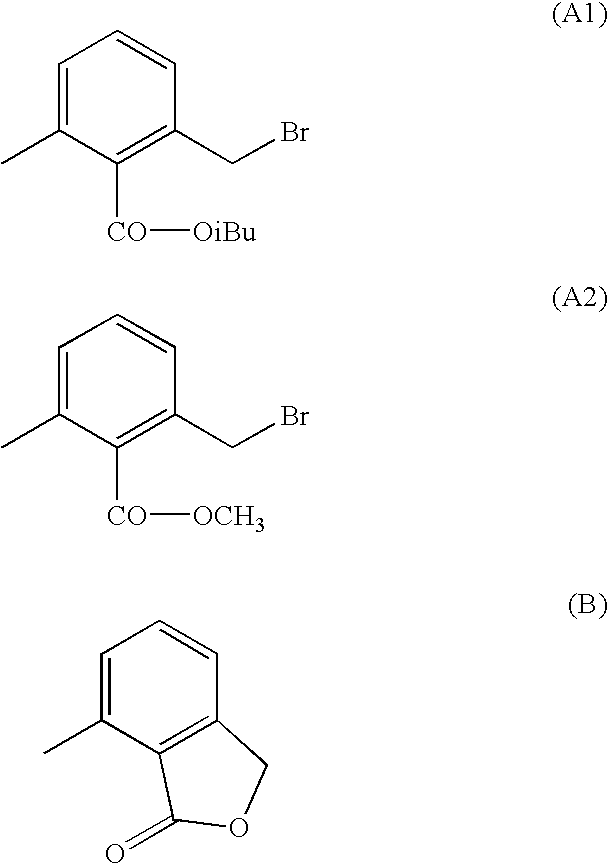

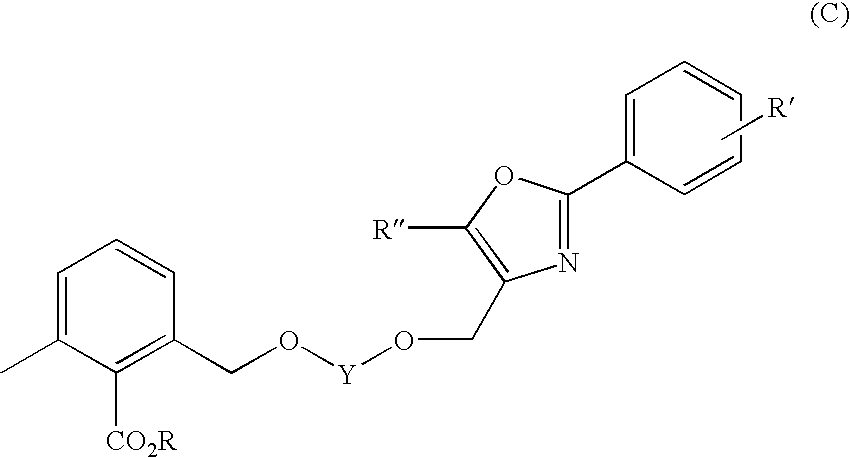

Synthesis of 2-chloromethyl-6-methylbenzoic ester

A process is described for preparing compounds of formula (I) where R is H, optionally halogen-substituted alkyl, cycloalkyl, aryl, alkyl-aryl or heteroaryl, and, in alkyl and cycloalkyl, one or more CH2 groups may be replaced by —O—. The compounds of the formula (I) are valuable intermediates in the synthesis of PPAR agonists.

Owner:SANOFI AVENTIS DEUT GMBH

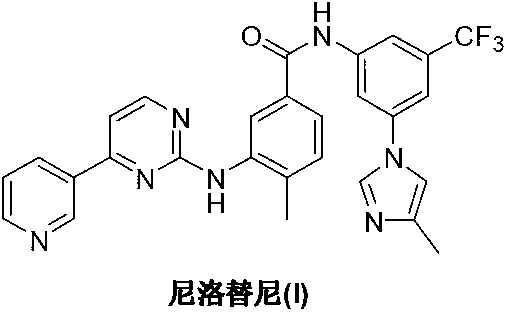

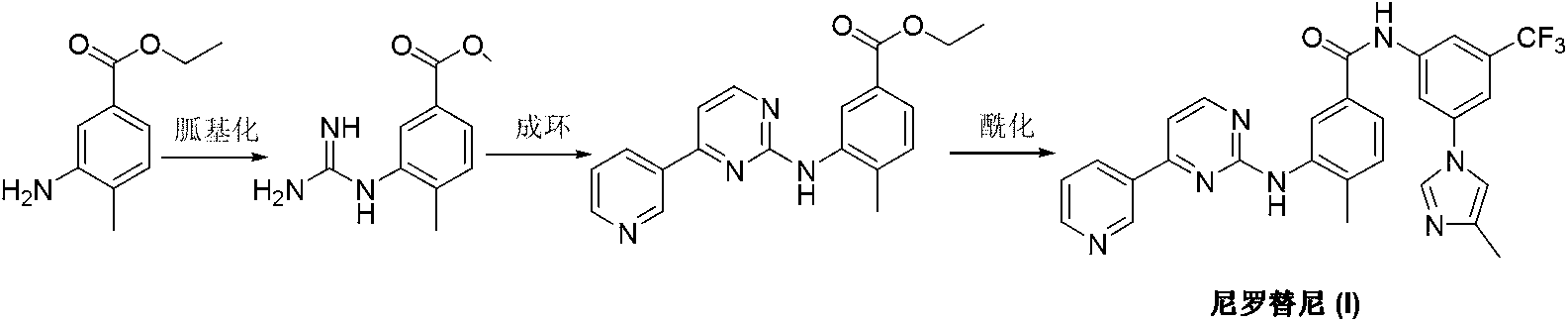

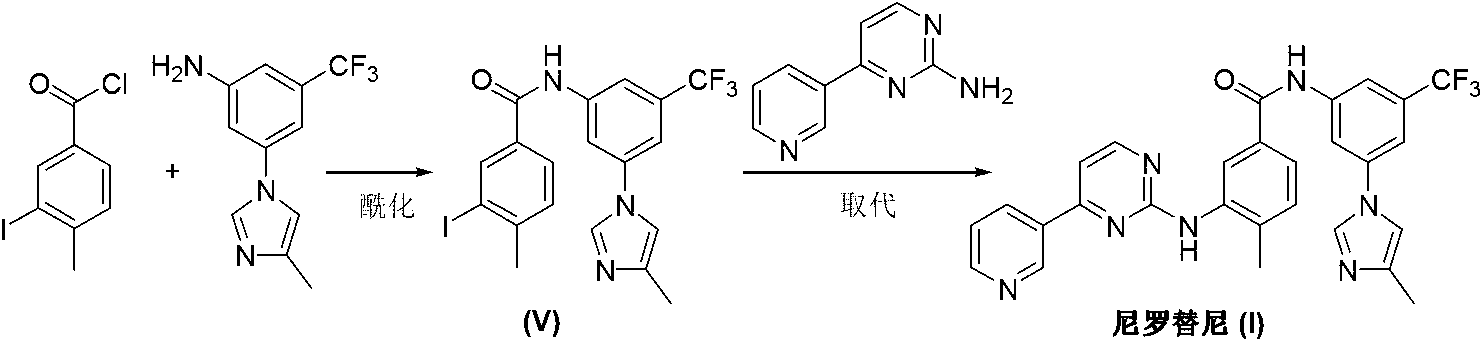

Preparation method of nilotinib

InactiveCN103254175AProduction is easy to controlImprove product qualityOrganic chemistryTechnology developmentMethylbenzoprim

The invention discloses a preparation method of nilotinib. The preparation method comprises the following steps of carrying out one-step condensation reaction on 4-(3-pyridyl)-2-pyrimidone (II), 3-amino-4-methyl benzoate (III) and 5-(4-methyl-1H-imidazole-1-yl)-3-trifluoromethyl phenylamine (IV) under the action of an organic alkali and a condensing agent to obtain nilotinib (I). The preparation method has the advantages that raw materials are easily available, the process is simple, conditions are mild, the environment is optimized, and quality is improved; therefore, the preparation method is suitable for industrial production and capable of promoting the economy and technology development of the raw medicine.

Owner:SUZHOU MIRACPHARMA TECH +1

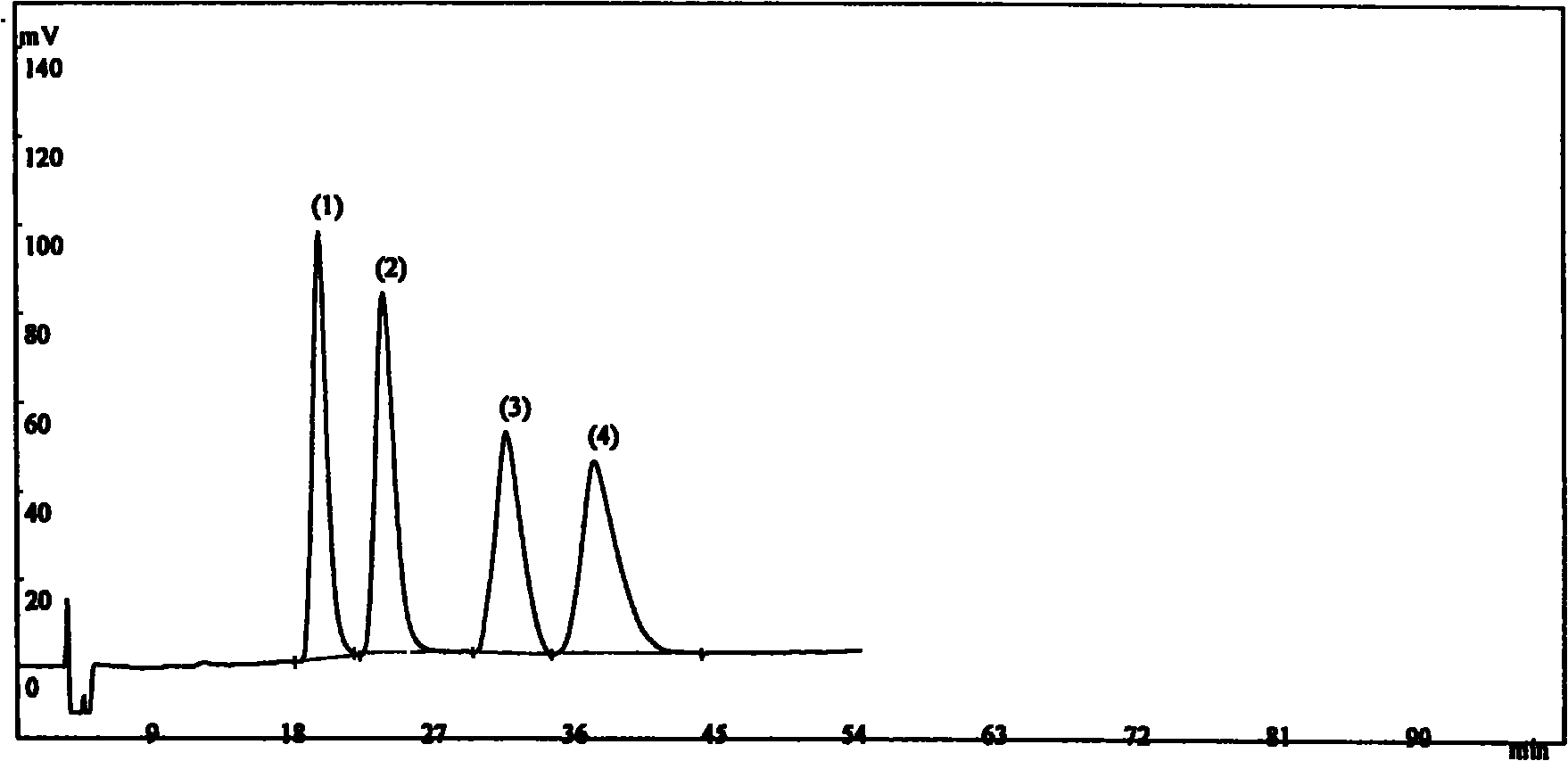

Method used for separating and measuring 2-chloromandelic acid enantiomers via HPLC

The invention discloses a method used for separating and measuring 2-chloromandelic acid enantiomers via HPLC. The method comprises following steps: R-2-chloromandelic acid samples are subjected to separating measuring via HPLC, wherein in separating measuring, cellulose-tri-4-methyl benzoate_chiral chromatographic column is taken as a stationary phase chiral chromatographic column, a mixed solution of alkanes and low alcohols is taken as a mobile phase for isocratic elution. The method is capable of realizing separating and measuring 2-chloromandelic acid enantiomers simply, rapidly, and accurately.

Owner:WUHAN WUYAO PHARMA

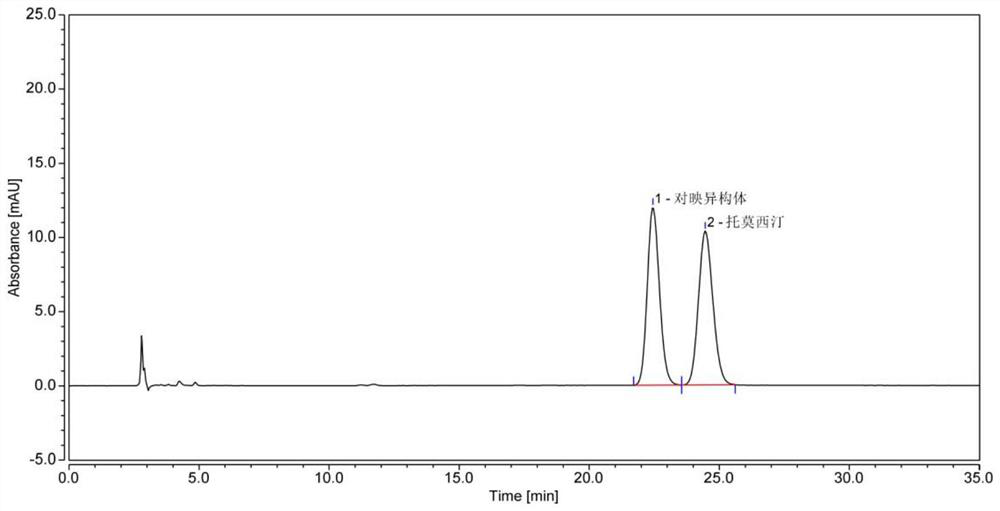

Method for detecting atomoxetine hydrochloride enantiomer by reversed-phase liquid chromatography

ActiveCN113358773AEfficient separationStable performance of chromatographic mediumComponent separationBenzoic acidPotassium hexafluorophosphate

The invention discloses a method for detecting atomoxetine hydrochloride enantiomer by reversed-phase liquid chromatography, which belongs to the field of pharmaceutical analysis, and adopts a polysaccharide derivative reversed-phase coating type chiral chromatographic column of which the surface of silica gel is coated with cellulose-tri (4-methyl benzoate) as a filler; and a mixed solution of a potassium hexafluorophosphate solution and acetonitrile is used as a mobile phase, the column temperature is 25-35 DEG C, the flow velocity is 0.5-0.8 ml / min, an ultraviolet detector is adopted, and the wavelength is 200-250 nm. According to the present invention, the atomoxetine hydrochloride and the enantiomer can be directly and effectively separated, the accuracy of the detection result is good, the sensitivity is high, and compared with the existing normal phase chromatography or precolumn derivatization reverse chromatography, the operation is simple, the cost is low, and the analysis time is short, such that the good guarantee is provided for the quality control of the atomoxetine hydrochloride and the preparation thereof.

Owner:JIANMIN PHARMA GRP CO LTD

A method for co-producing methylbenzoic acid, methylbenzoic acid ester and phthalic acid diester

ActiveCN108047034BRaw materials are easy to getStructural diversificationOrganic compound preparationCarboxylic acid esters preparationBenzoic acidXylylene

The invention discloses a method for co-producing methyl benzoic acid, methyl benzoate and phthalic acid diester, comprising: (1) continuously feeding xylene, a catalyst and an oxygen-containing gas into an oxidation reactor to carry out reaction, by controlling the amount of oxygen-containing gas to control the tail oxygen concentration to be no more than 5%, to obtain an oxidation reaction liquid; (2) enter the obtained oxidation reaction liquid into an initial distillation tower for rectification separation, to obtain low boiling point components and initial (3) enter the rectifying tower still liquid into the rectifying tower for rectification to obtain toluic acid product and rectifying tower still liquid; (4) mix the rectifying tower tower liquid with alcohol , carry out the esterification reaction, control the reaction end point to be that the content of toluic acid<0.5wt%, obtain the esterification reaction solution; (5) carry out rectification separation with the esterification reaction solution obtained, obtain methyl benzoic acid ester respectively and diester phthalate products. The invention has the advantages of simple process, less equipment investment, environmental protection and good comprehensive economic benefits.

Owner:JIANGXI KEYUAN BIOPHARM

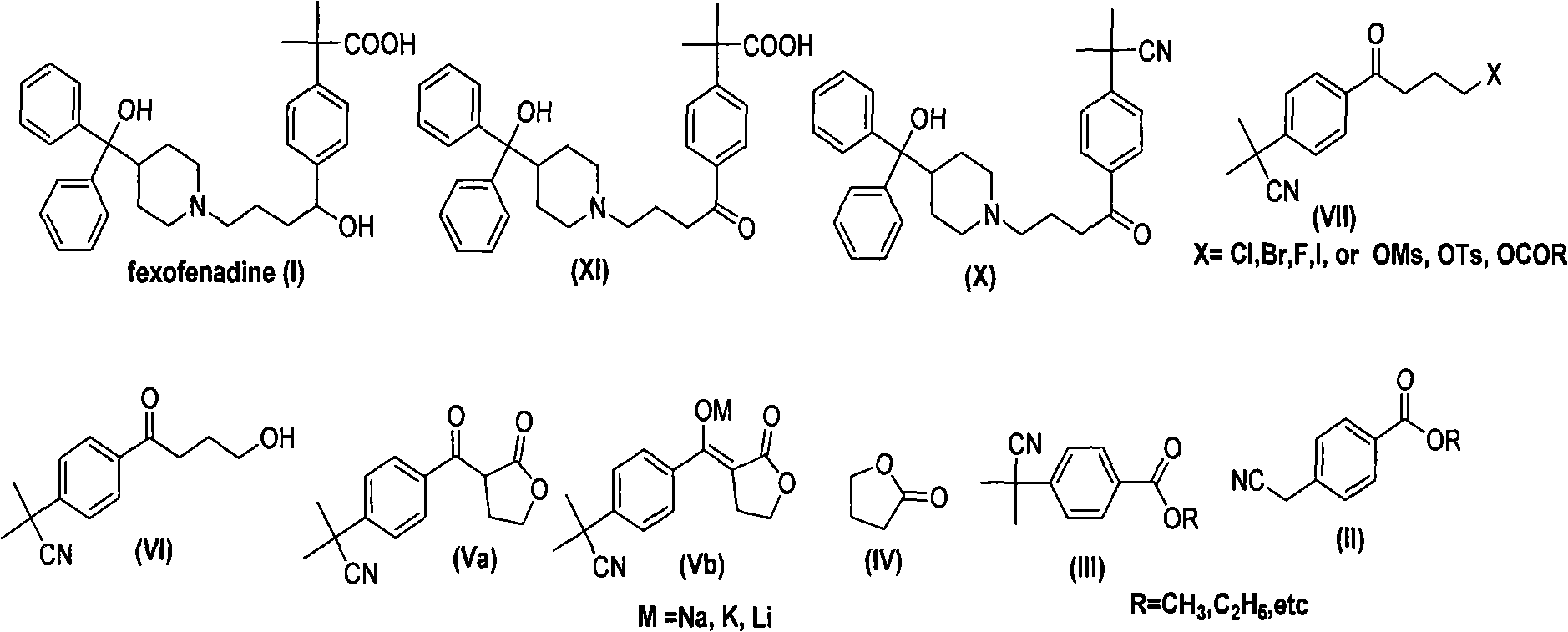

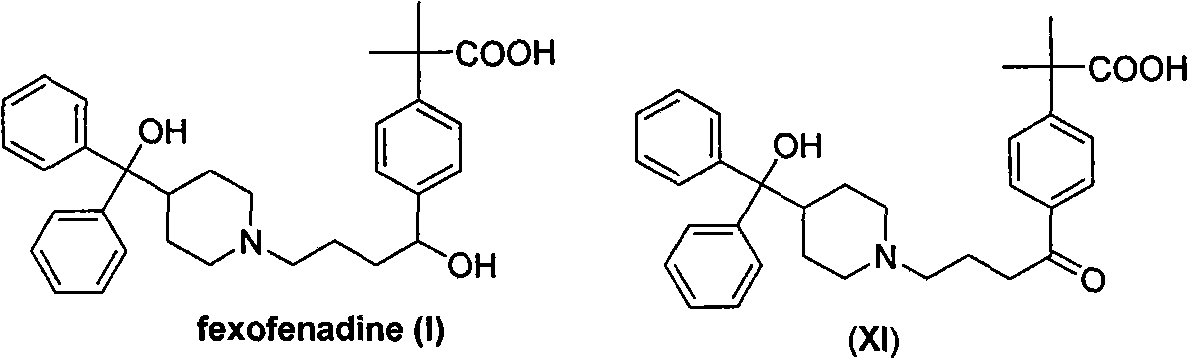

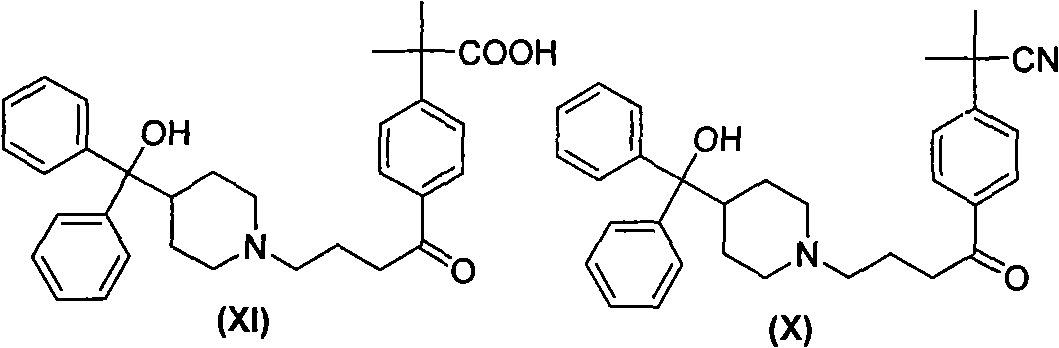

Synthesizing route and preparation method of high-purity fexofenadine and intermediate thereof

ActiveCN102070512AReduce total usageRaw materials are easy to getCarboxylic acid nitrile preparationOrganic compound preparationFexofenadinePara position

The invention relates to a preparation method of high-purity fexofenadine (chemical name (+ / -)-4-[1-hydroxyl-4-[4-(hydroxyldiphenylmethyl)-1-piperidyl]butyl]-alpha, alpha-dimethylphenylacetic acid) and an intermediate thereof and a novel synthesizing route. The method comprises the following steps of: with p-cyanomethylbenzoate (II) as a raw material, and with a new compound (Va) or salt (Vb) thereof as a key intermediate, hydrolyzing, esterifying or halogenating to obtain a compound (VII); and condensing, hydrolyzing and reducing with a piperdinol compound (VIII) to obtain a high-purity fexofenadine type compound (I) without para-position substitution. The invention has the advantages of simple reaction, convenience for postprocessing, higher yield and high purity of generated products and is a more ideal preparation method of fexofenadine.

Owner:ZHEJIANG HUAHAI PHARMACEUTICAL CO LTD +1

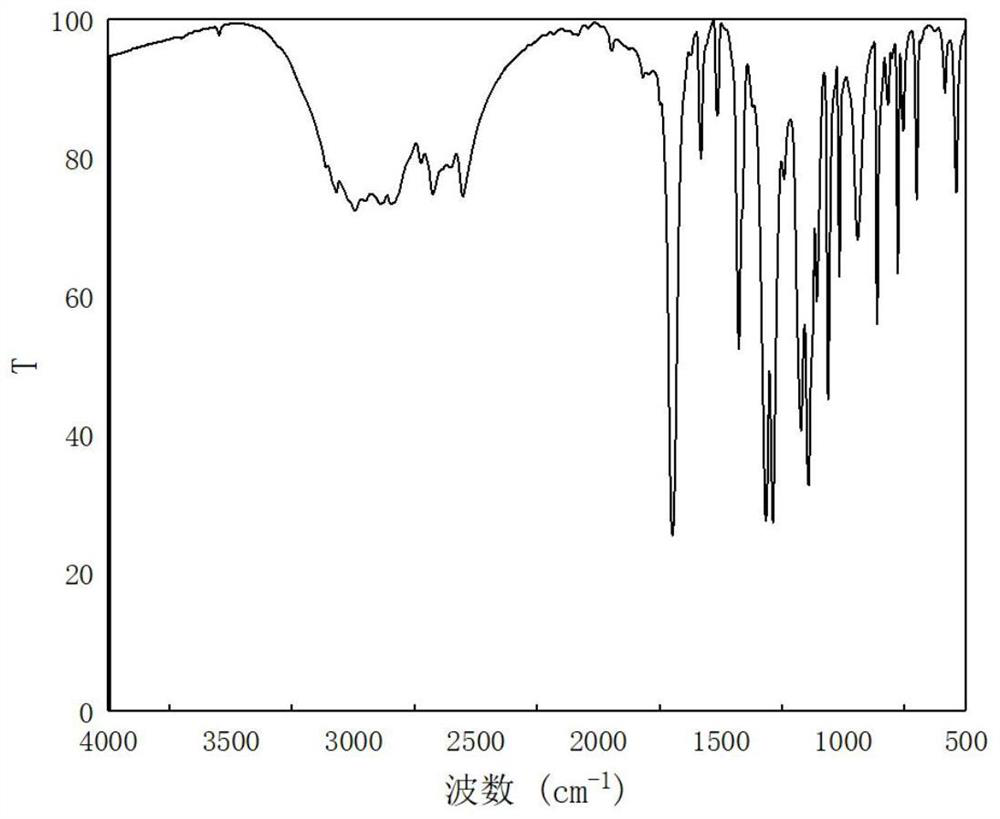

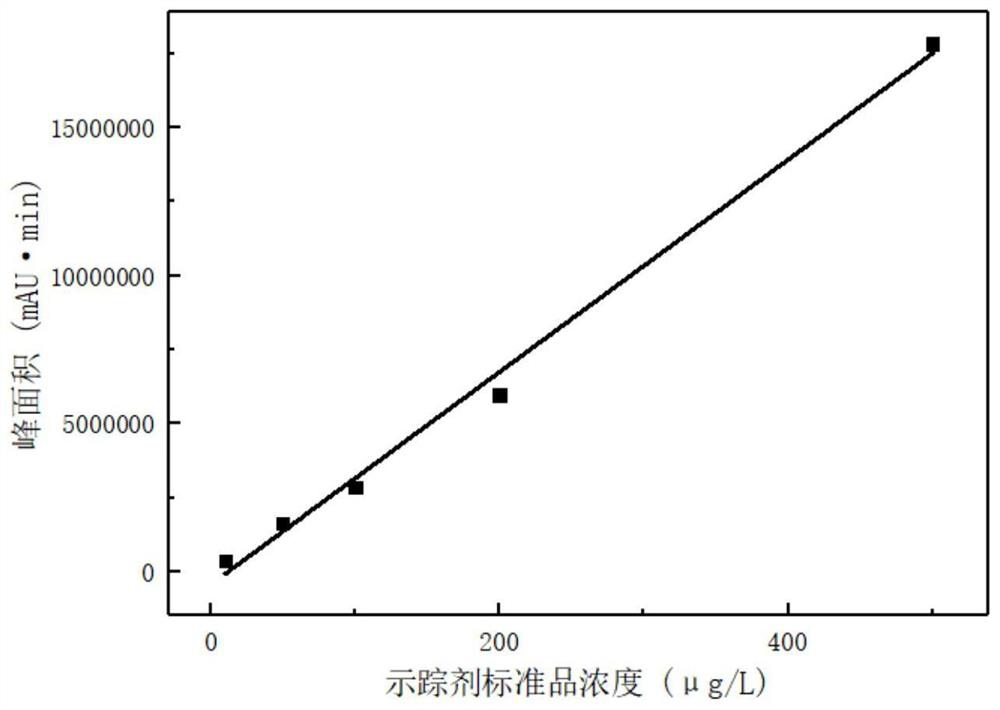

Chemical tracer agent for fracturing as well as preparation method and application thereof

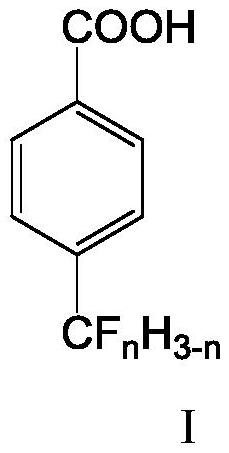

PendingCN112851501AReduce background concentrationLess formation adsorptionOrganic compound preparationConstructionsBenzoic acidBenzene

The invention relates to a chemical tracer for fracturing and a preparation method and application thereof. The chemical tracer agent is fluoromethyl benzoic acid. The preparation method of the chemical tracer takes p-chlorofluoromethyl benzene as an initial raw material, and comprises a preparation step of a fluoromethyl benzene Grignard reagent, a preparation step of fluoromethyl benzoate and a preparation step of fluoromethyl benzoic acid. The invention further provides application of p-fluoromethyl benzoic acid as a chemical tracer in oil exploitation, trace detection can be realized, and the detection precision is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

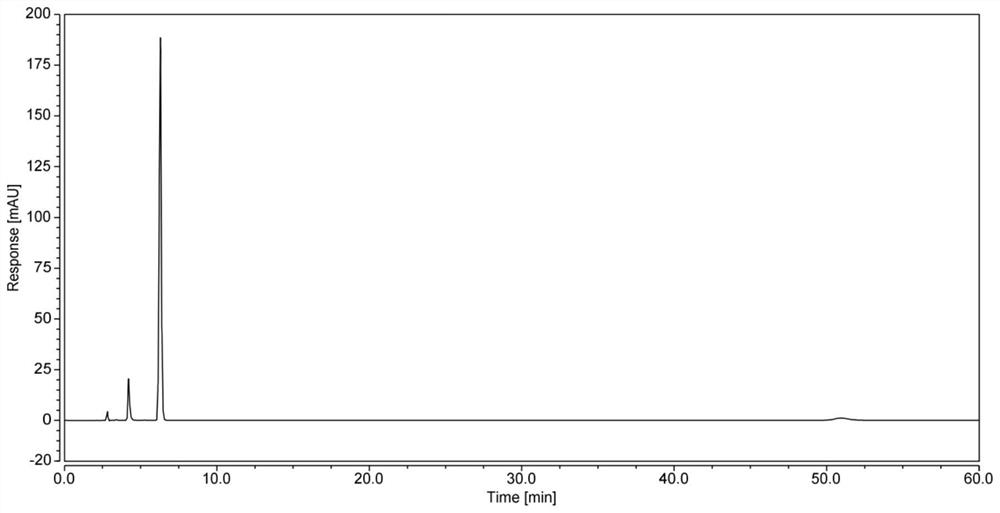

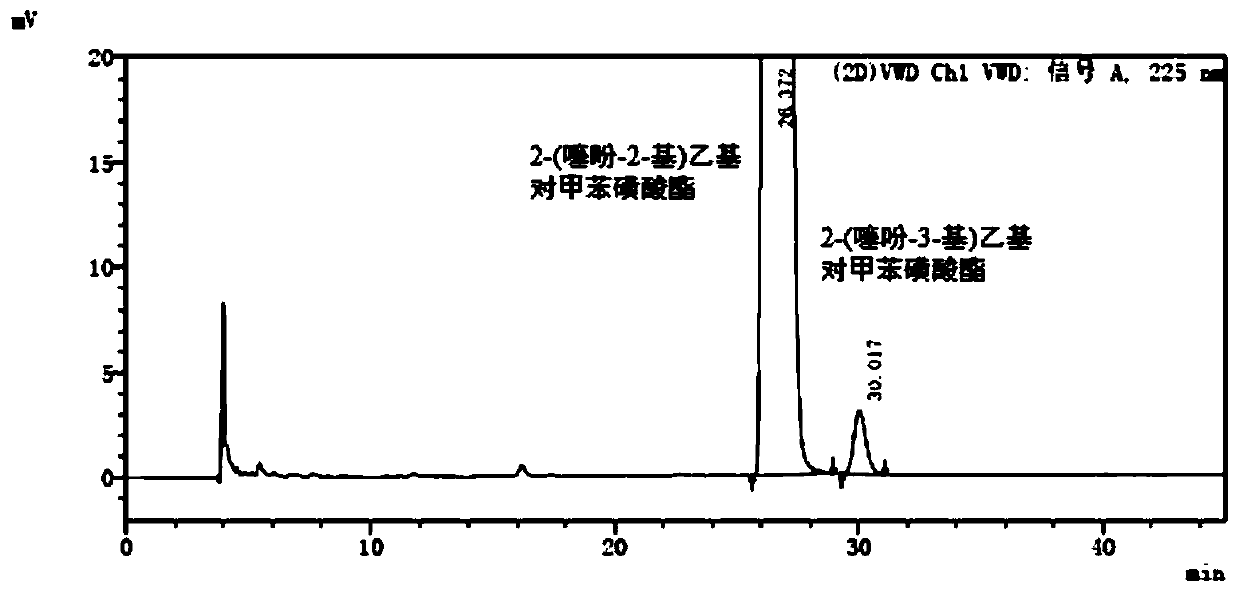

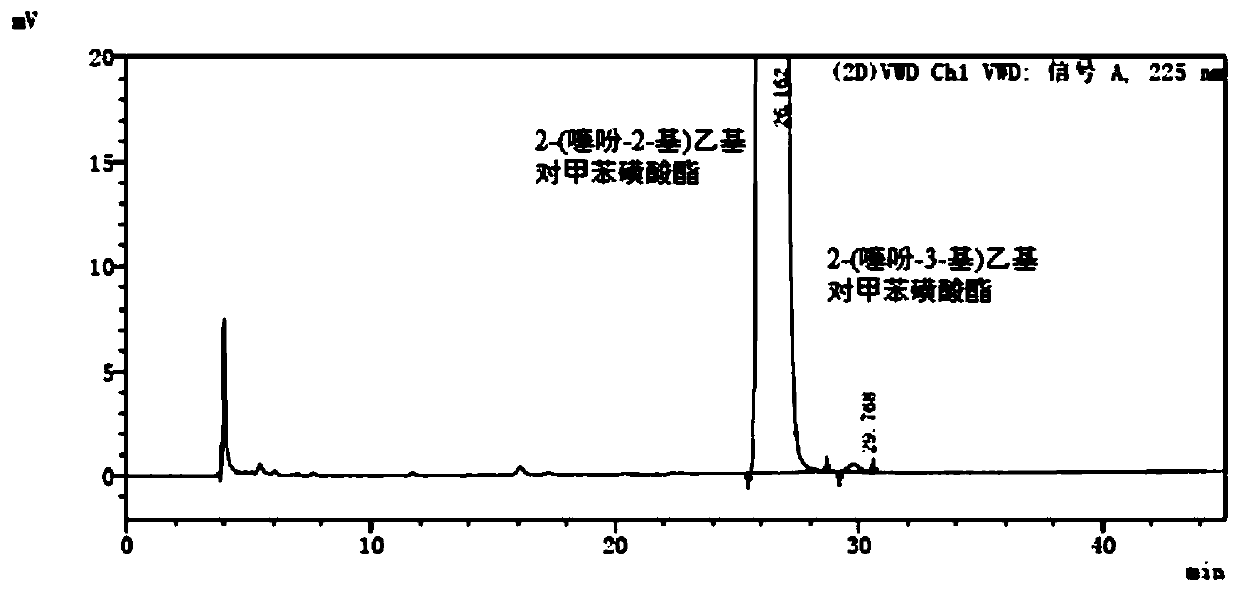

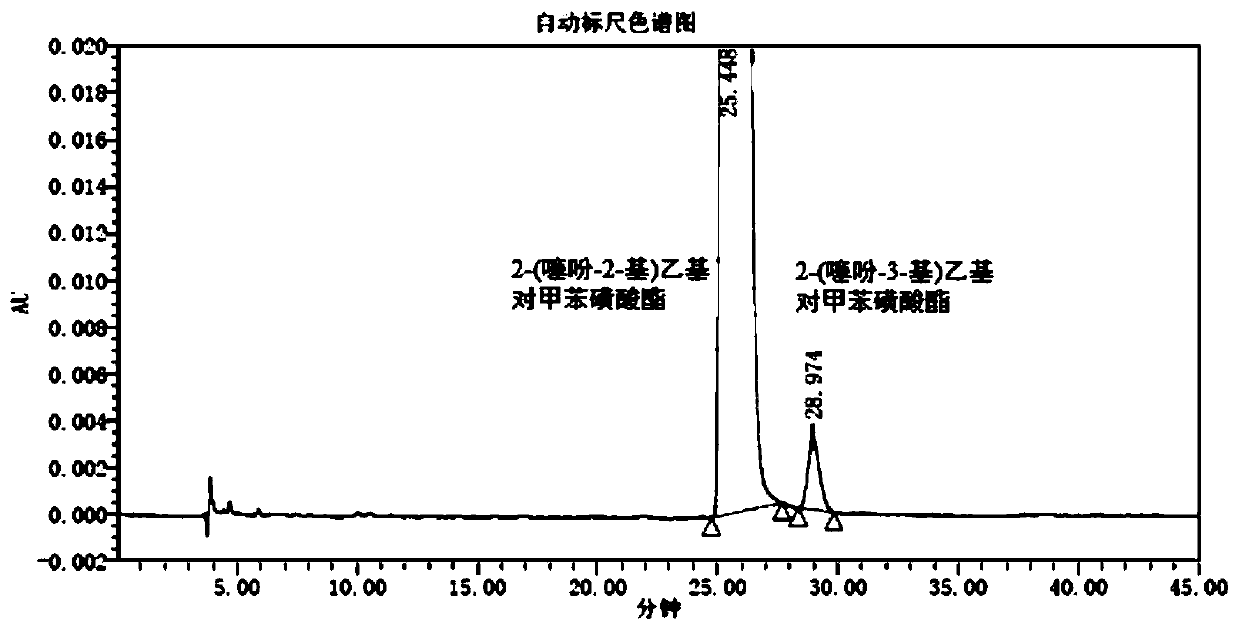

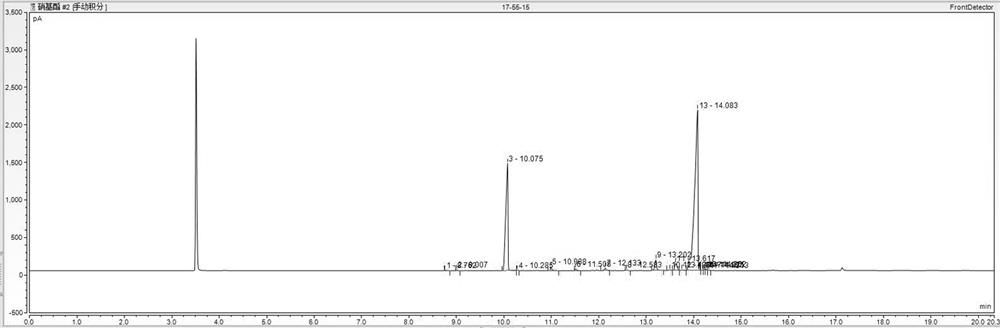

Detection method of 2-(thiophene-2-yl)ethyl p-toluenesulfonate and isomers thereof

The invention belongs to the field of medicines, and particularly relates to a detection method and application of 2-(thiophene-2-yl)ethyl p-toluenesulfonate and isomers thereof. The detection methodcomprises the steps of preparing a test solution, a reference solution and a system applicability solution; and carrying out high performance liquid chromatography detection on the test solution, thereference solution and the system suitability solution, wherein the detection conditions are as follows: the chromatographic column comprises a chiral chromatographic column taking silica gel coated with cellulose-tri(4-methyl benzoate) as a filling agent, the mobile phase comprises a mixed solution of n-hexane and absolute ethyl alcohol, and the flow velocity of the mobile phase is 0.7mL / min-0. 9mL / min, the detection wavelength ranges from 220nm to 227nm, the column temperature of the chromatographic column is 25-40 DEG C. The detection method is good in sensitivity, high in accuracy, good inreproducibility, convenient to operate and good in durability, the quality of 2-(thiophene-2-yl)ethyl p-toluenesulfonate can be effectively controlled, and the detection method has important significance in controlling the quality of clopidogrel hydrogen sulfate from the source.

Owner:北京鑫开元医药科技有限公司 +1

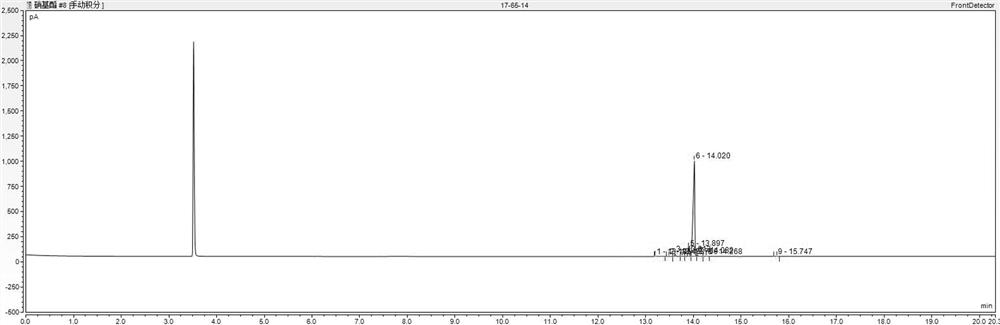

HPLC (High Performance Liquid Chromatography) method for measuring content of D-4-methylsulfonylphenyl serine ethyl ester

ActiveCN101832981AEfficient separationGood linear relationshipComponent separationCelluloseHplc method

The invention discloses an HPLC (High Performance Liquid Chromatography) method for measuring content of D-4-methylsulfonylphenyl serine ethyl ester, comprising the following steps of: preparing a solution from D-4-methylsulfonylphenyl serine ethyl ester with a mixed solvent of normal propyl alcohol and carbinol; filtering with a microporous membrane; coating the chiral column of the stationary phase of cellulose-tris (4-methyl benzoate) on the surface of silica gel; detecting in the presence of proper detection wavelength, flow rate and column temperature by taking a mixed solution of normal hexane, an organic modifier and organic base; and then calculating the content of a sample according to a spectrogram. The D-4-methylsulfonylphenyl serine ethyl ester and L-4-methylsulfonylphenyl serine ethyl ester can be effectively separated, and the content of the D-4-methylsulfonylphenyl serine ethyl ester can be accurately measured by adopting the method. The method is simple and convenient, reliable and rapid and has high sensitivity and good repeatability and specificity and lays foundation for the formulation of the quality standard of the D-4-methylsulfonylphenyl serine ethyl ester.

Owner:HUBEI LONGXIANG PHARMA TECH CO LTD

Preparation method of sofosbuvir intermediate

ActiveCN113354700AGood choiceReduce generationSugar derivativesOrganic chemistry methodsBenzoic acidChlorobenzene

The invention relates to the technical field of biopharmacy, in particular to preparation of a sofosbuvir intermediate, and more particularly relates to a preparation method of the sofosbuvir intermediate ((2R, 3R, 4R)-3-benzoyloxy-4-fluoro-5-chloro-4-methyltetrahydrofuran-2-yl) methyl benzoate; and a compound shown in a formula a reacts with modified red aluminum to prepare a compound shown in a formula b, then the compound shown in the formula b is subjected to a chlorination reaction in an oxalyl chloride / chlorobenzene solution to prepare a compound shown in a formula c, and finally the compound shown in the formula c reacts with a compound with a structure shown in a formula e to prepare a target compound shown in a formula d. The preparation process is simple in reaction condition, easy to operate and low in cost; the hydrolysis operation is reduced in the post-treatment process of the chlorination stage, so that the wastewater amount is reduced, and the method is more environment-friendly; and the preparation process disclosed by the invention is high in yield, high in product purity, more stable in product and suitable for large-scale production.

Owner:JIANGSU ALPHA PHARM CO LTD

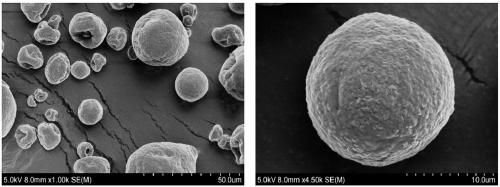

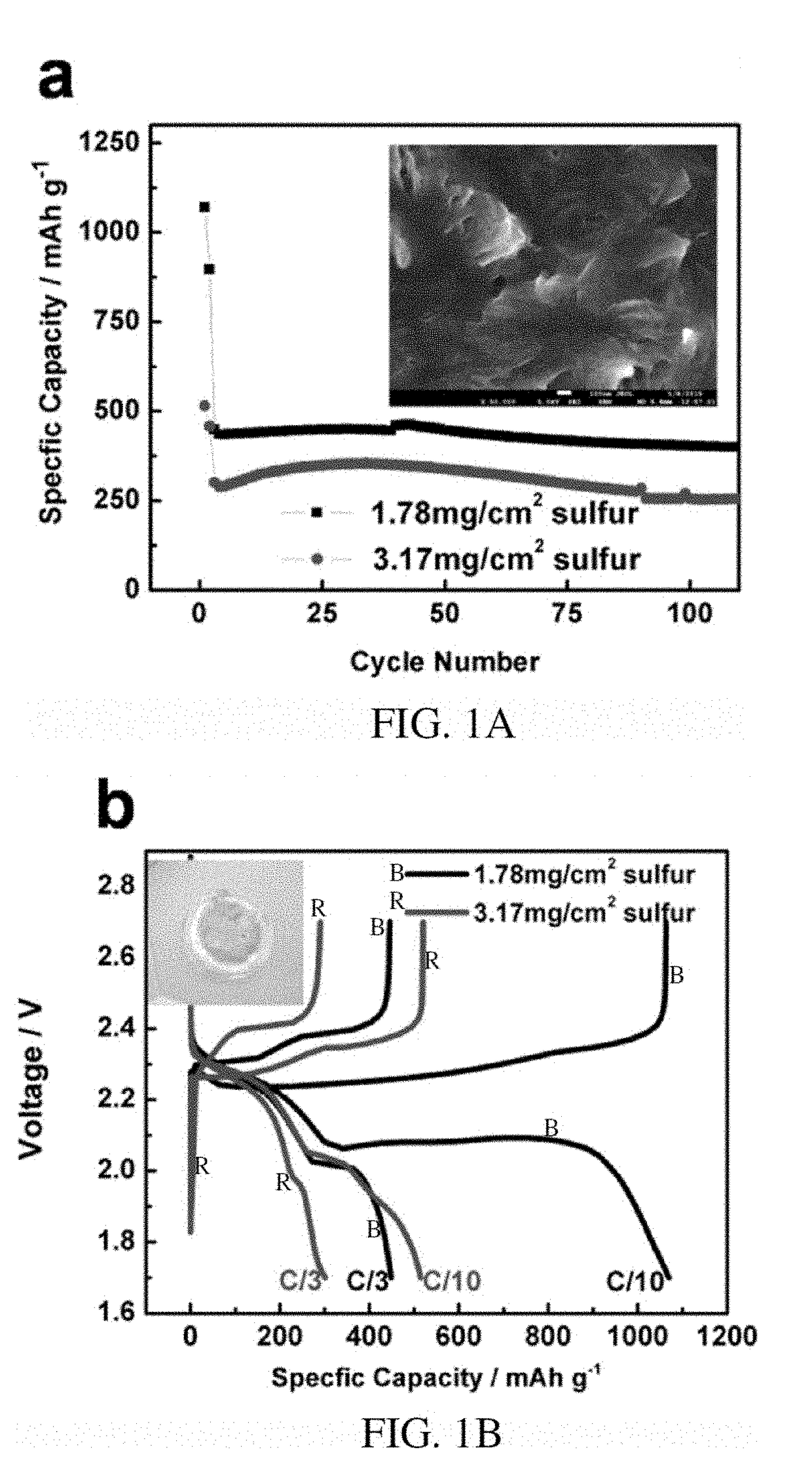

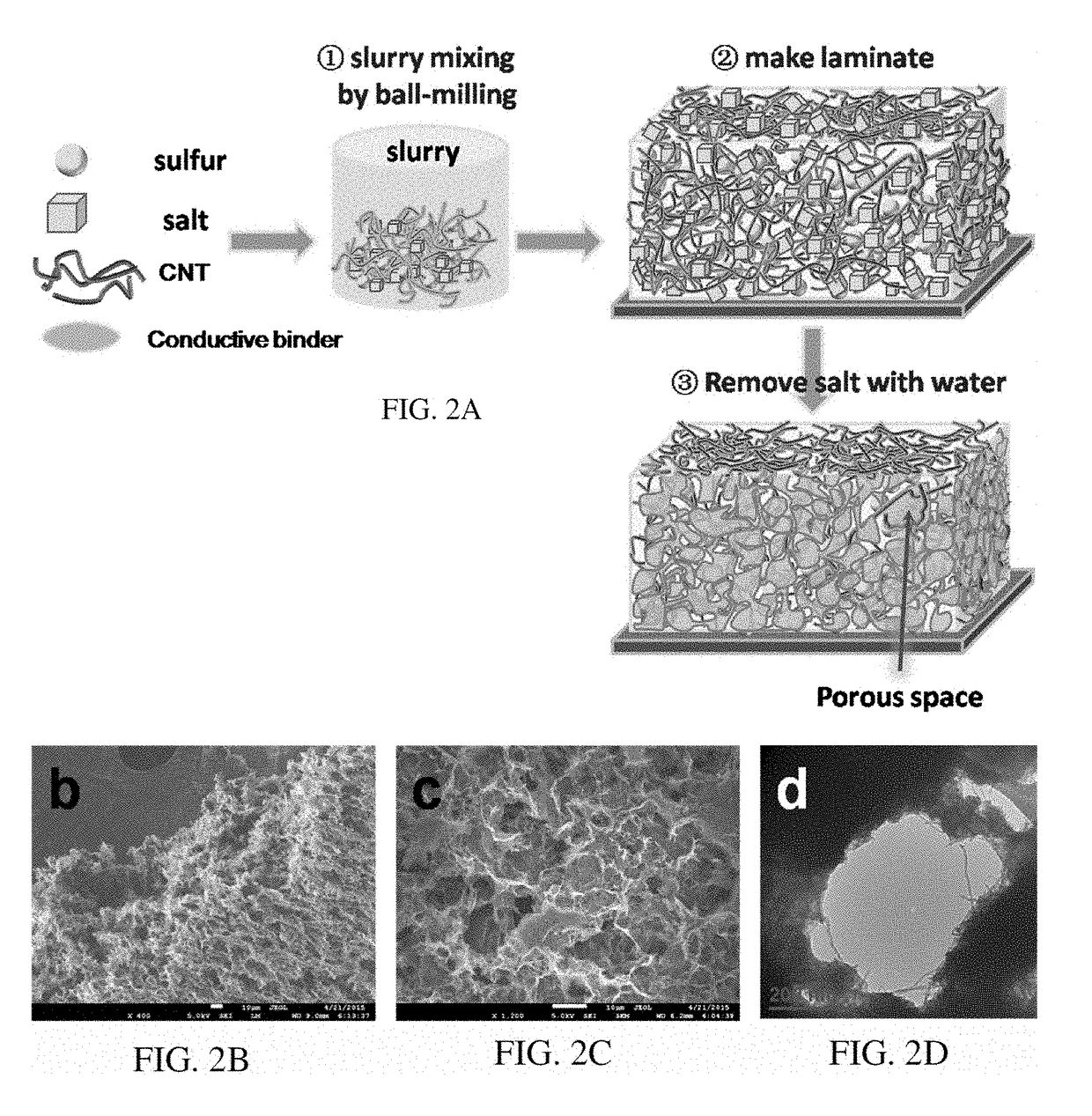

Three Dimensional Ant-nest Electrode Structures for High Loading and High Sulfur Ratio Lithium-Sulfur Batteries

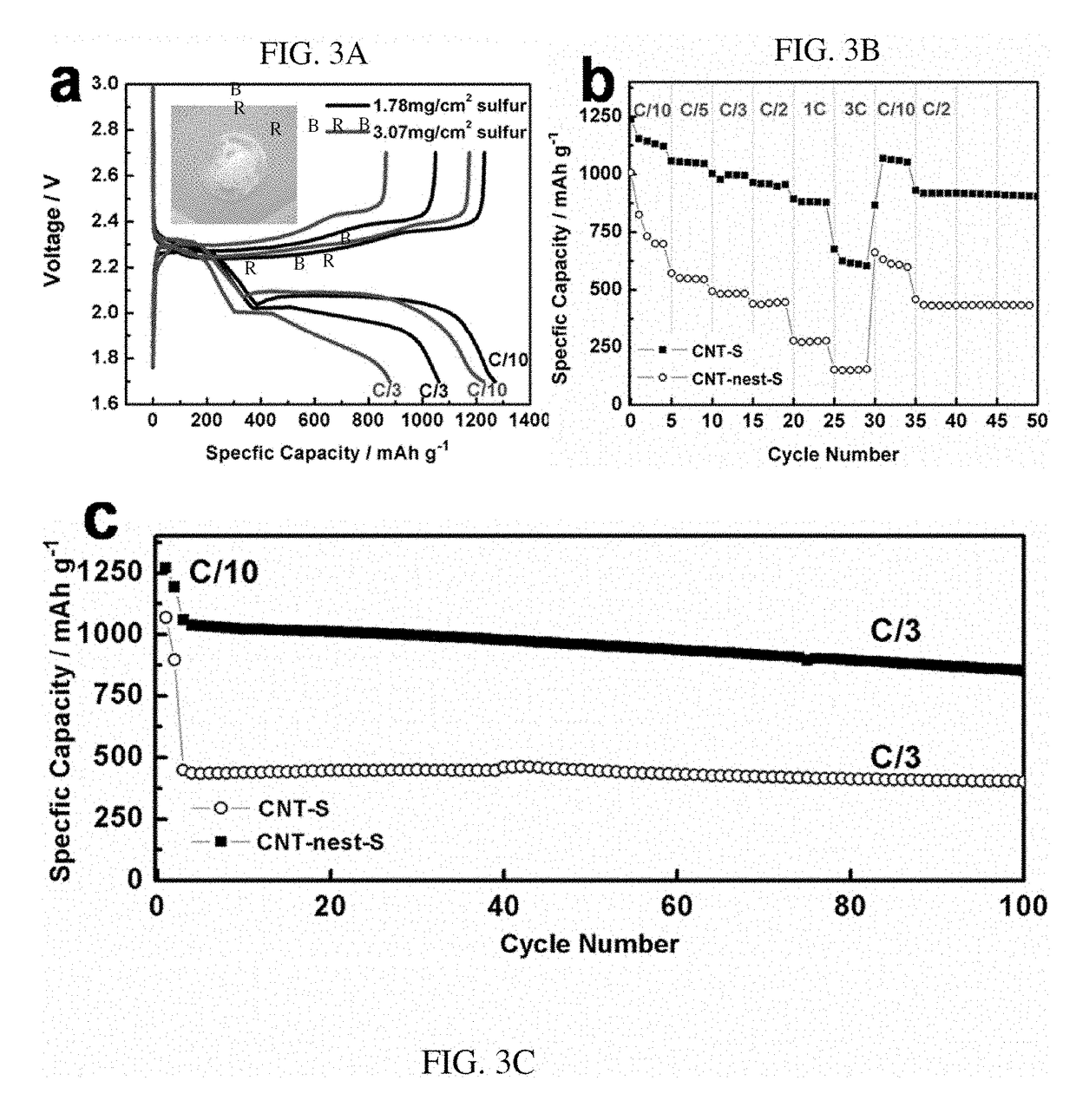

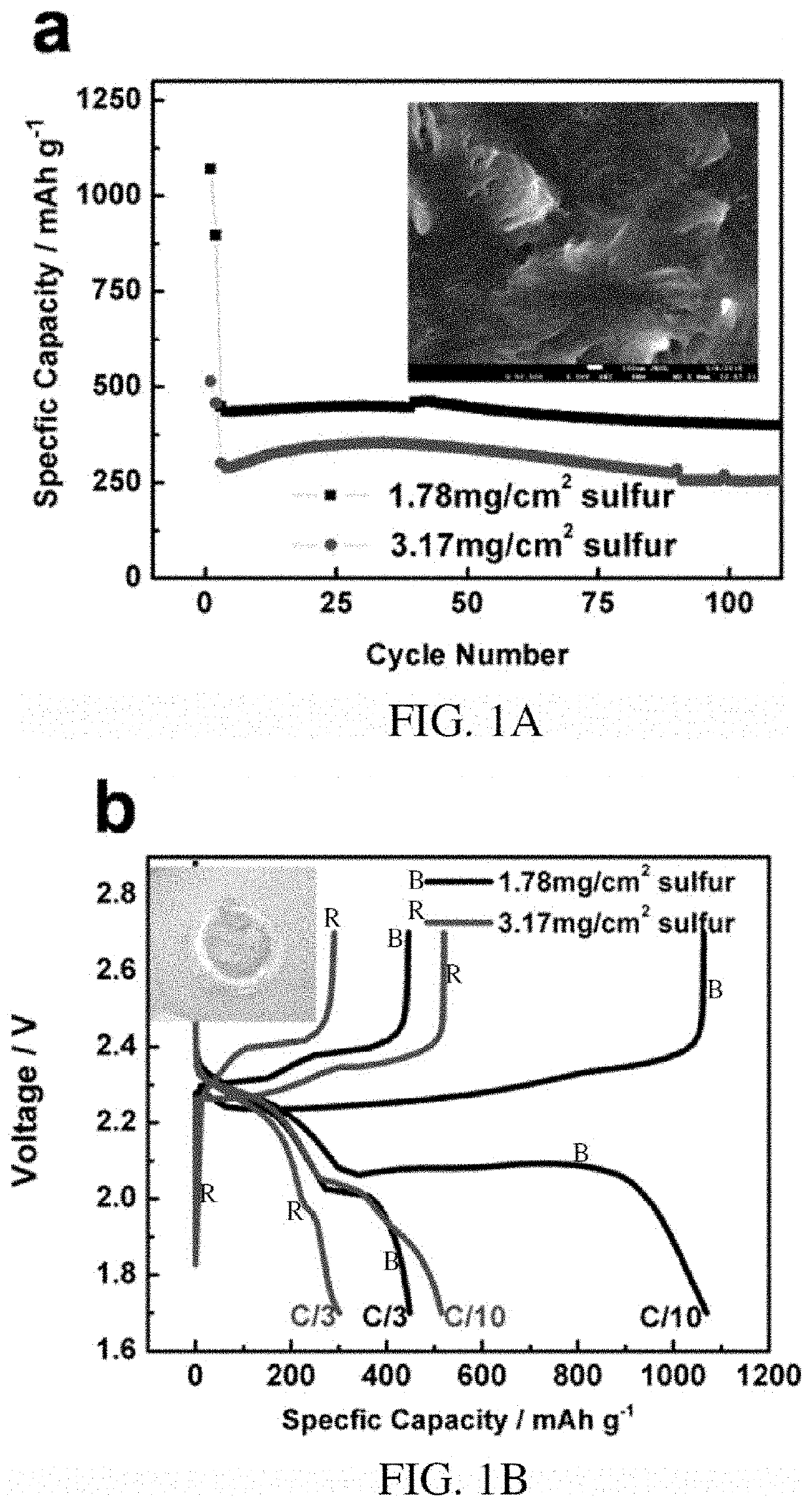

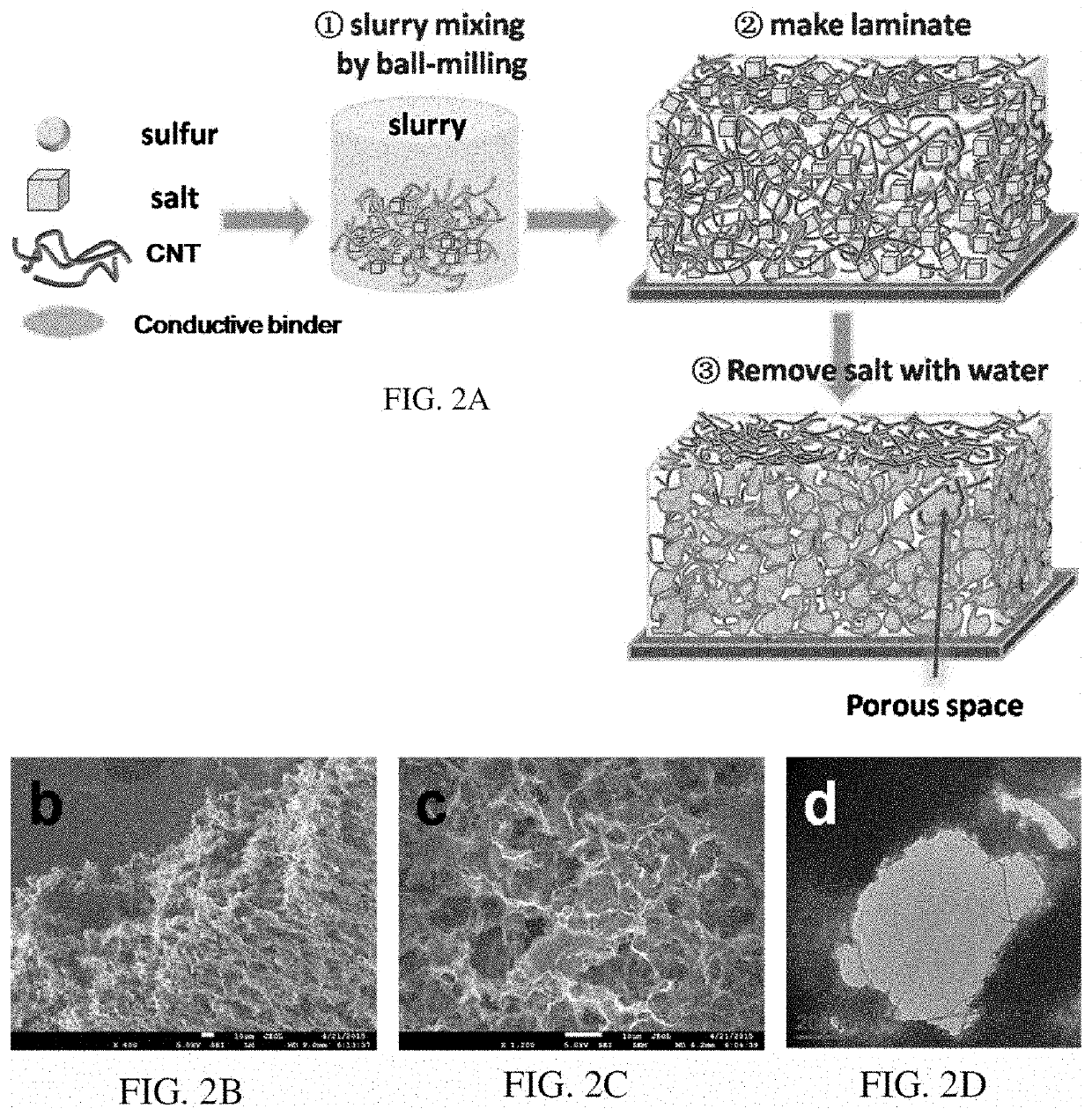

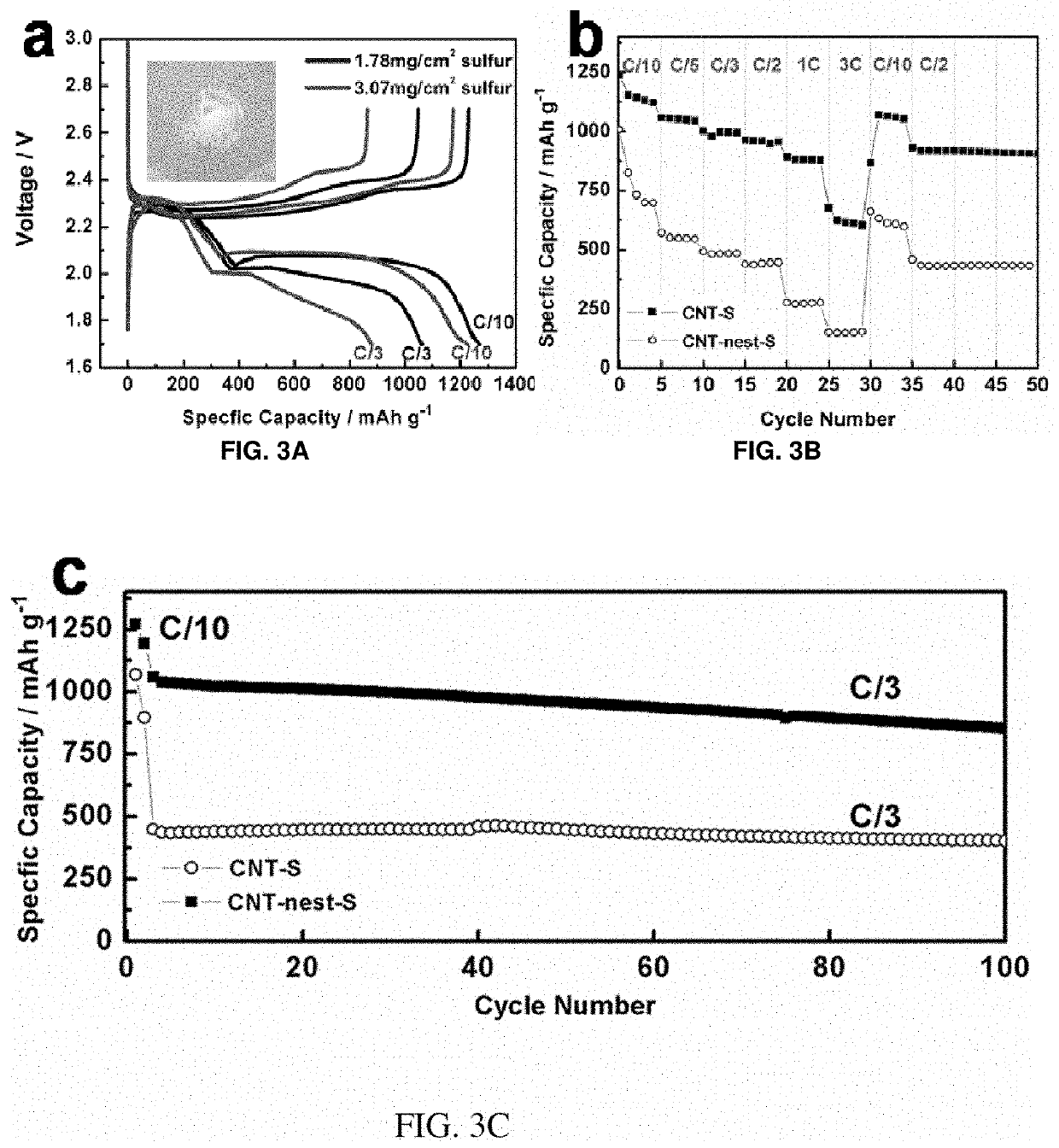

The present invention provides for a composition of matter comprising: Poly(9,9-dioctylfluorene-co-fluorenone-co-methylbenzoic ester) (PFM), carbon nanotubes (CNT), and sulfur particles nanocomposite, wherein the nanocomposite is porous. The present invention also provides for an electrode comprising: Poly(9,9-dioctylfluorene-co-fluorenone-co-methylbenzoic ester) (PFM), carbon nanotubes (CNT), and sulfur particles nanocomposite, wherein the nanocomposite is porous. The present invention also provides for a lithium sulfur (Li—S) battery comprising: an electrode comprising Poly(9,9-dioctylfluorene-co-fluorenone-co-methylbenzoic ester) (PFM), carbon nanotubes (CNT), and sulfur particles nanocomposite, wherein the nanocomposite is porous.

Owner:RGT UNIV OF CALIFORNIA

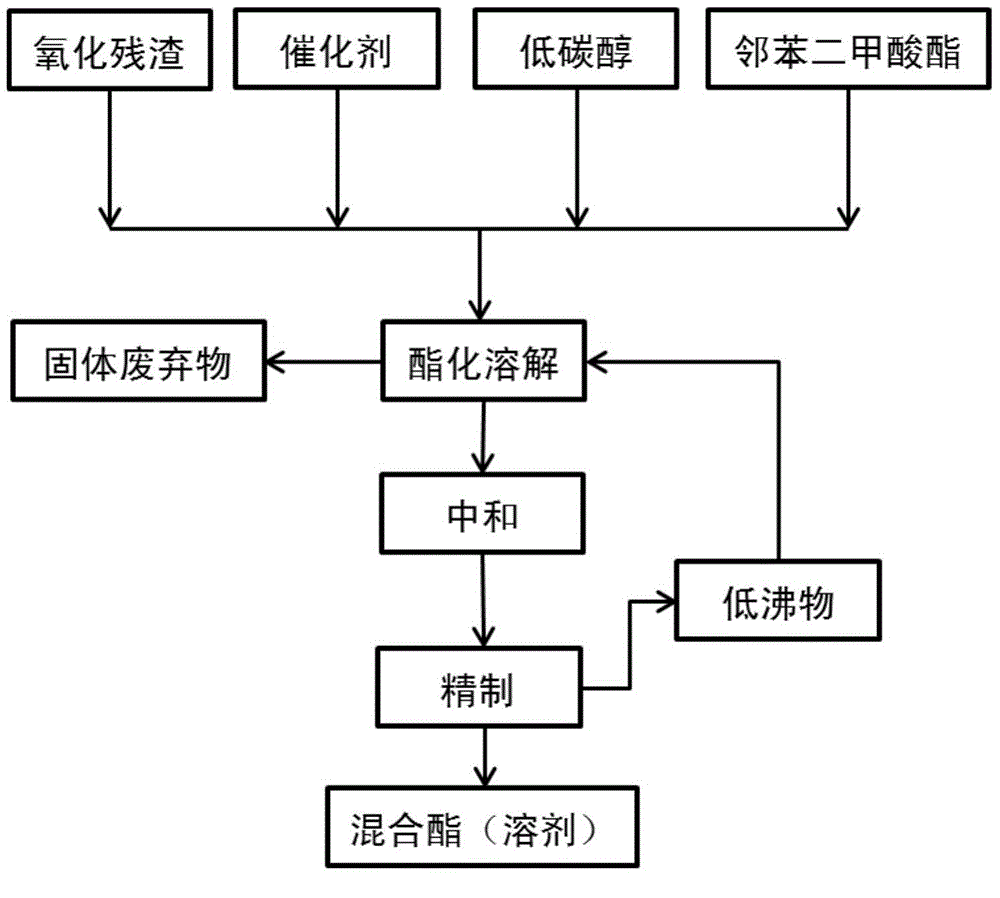

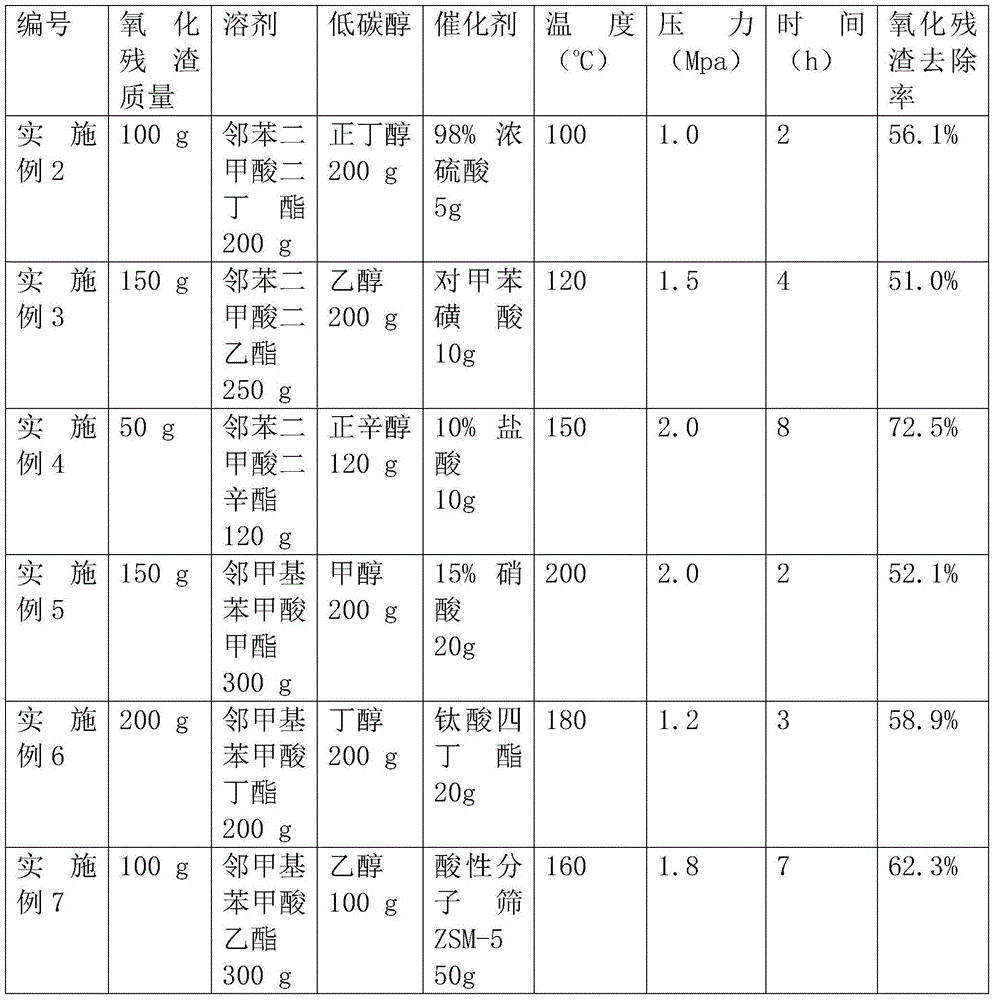

Treatment method of O-xylene liquid phase oxidation residues

ActiveCN106187766AHigh removal rateEfficient recyclingOrganic compound preparationCarboxylic acid esters separation/purificationO-XyleneAlcohol

The invention discloses a treatment method of O-xylene liquid phase oxidation residues. The method comprises the following steps of adding phthalate, or O-methyl benzoate or a mixture of the phthalate and the O-methyl benzoate to oxidation residues, and performing catalysing, dissolving and esterifying on a catalyst with low carbon and alcohol and low catalysis quantity so as to obtain mixed crude ester; and recovering most of solid residues, so that 50% or above of discharged solid waste can be reduced. After refining, the crude ester can be used as an o-xylene liquid phase oxidation solvent to return to an oxidation tower for use. According to the method, the o-xylene liquid phase oxidation residues are comprehensively used, so that the discharged solid waste is greatly reduced, and recycling of industrial waste residue is realized.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Poly(9,9-dioctylfluorene-co-fluorenone-co-methylbenzoic ester), carbon nanotubes, and sulfur nanocomposite, electrode and lithium-fulfur battery including the same

ActiveUS10833320B2Electrode carriers/collectorsActive material electrodesPolydioctylfluoreneMethylbenzoprim

The present invention provides for a composition of matter comprising: poly(9,9-dioctylfluorene-co-fluorenone-co-methylbenzoic ester)(PFM), carbon nanotubes (CNT), and sulfur particles nanocomposite, wherein the nanocomposite is porous. The present invention also provides for an electrode comprising: poly(9,9-dioctylfluorene-co-fluorenone-co-methylbenzoic ester)(PFM), carbon nanotubes (CNT), and sulfur particles nanocomposite, wherein the nanocomposite is porous. The present invention also provides for a lithium sulfur (Li—S) battery comprising: an electrode comprising poly(9,9-dioctylfluorene-co-fluorenone-co-methylbenzoic ester)(PFM), carbon nanotubes (CNT), and sulfur particles nanocomposite, wherein the nanocomposite is porous.

Owner:RGT UNIV OF CALIFORNIA

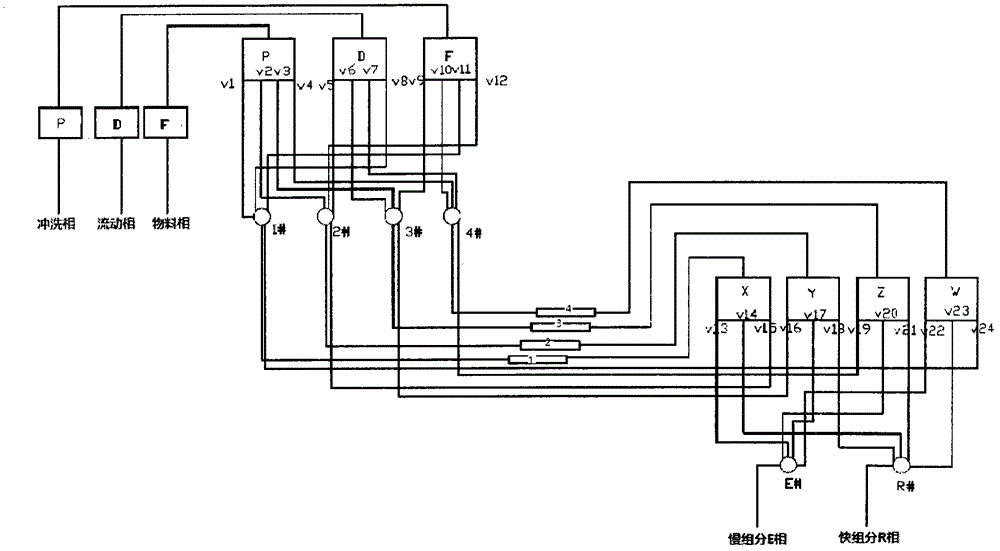

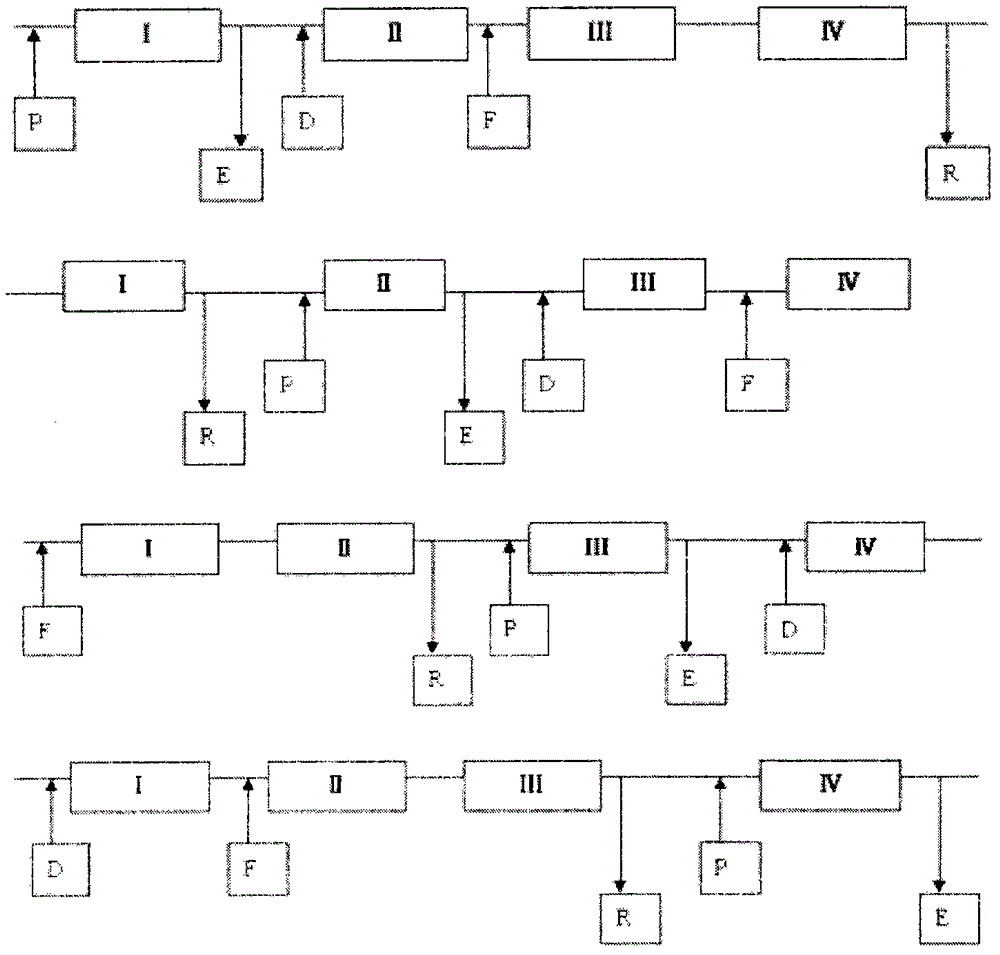

Method for preparing donepezil by virtue of simulated moving bed chromatographic separation

InactiveCN104557673ASimple processAvailable for industrial productionOrganic chemistryStationary phaseCellulose

The invention discloses a method for preparing donepezil by virtue of simulated moving bed chromatographic separation. A laevo isomer and a dextro isomer are separated out from the donepezil by adopting a chiral column Chiralcel-OJ and taking silica gel coated with cellulose-tri(4-methyl benzoate) as a stationary phase and absolute ethyl alcohol as a moving phase. Due to the continuity of the simulated moving bed chromatographic separation, the production efficiency can be greatly improved and the production cost can be reduced; the whole separation process does not involve with any toxic solvent.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Method for co-production 2-methyl-6-nitrobenzoic acid and 3-nitro-2-methylbenzoic acid

ActiveCN111718264ARealize joint productionOxidation safetyOrganic chemistryOrganic compound preparationXylyleneBenzoic acid

The invention discloses a method for co-production of 2-methyl-6-nitrobenzoic acid and 3-nitro-2-methylbenzoic acid. The method is characterized by comprising the following steps: (1) feeding 3-nitro-o-xylene and dilute nitric acid into an oxidation reaction kettle, carrying out heating, and conducting reacting under certain pressure by using oxygen as an oxidant; (2) after the reaction is finished, discharging an oxidation reaction solution to obtain a crude product; (3) washing the crude product with water, conducting esterifying, and performing distilling to recover a solvent after the reaction is finished, thereby obtaining an esterified concentrated solution; (4) adding alkali into the esterification concentrated solution to adjust a pH value, carrying out layering, and distilling anorganic layer under reduced pressure to recover 3-nitro-2-nitrobenzoic acid; and (5) extracting a water layer with an organic solvent, adjusting an pH value with an acid, and performing filtering anddrying to obtain the 2-methyl-6-nitrobenzoic acid. In a low-concentration nitric acid environment, 3-nitro-2-nitrobenzoic acid is produced and 2-methyl-6-nitrobenzoic acid is co-produced with oxygen used as an oxidizing agent, so the problems of low selectivity of 3-nitro-o-xylene in an oxidation process and high risks in a concentrated nitric acid oxidation process are solved.

Owner:JIANGSU YONGAN CHEM CO LTD

A kind of preparation method of telbivudine

ActiveCN106478752BHarm reductionStable physical and chemical propertiesSugar derivativesSugar derivatives preparationN dimethylformamideMethylbenzoprim

Owner:SICHUAN KELUN PHARMA RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com