High-efficiency porous Ni-Mo hydrogen evolution electrode and preparation method thereof

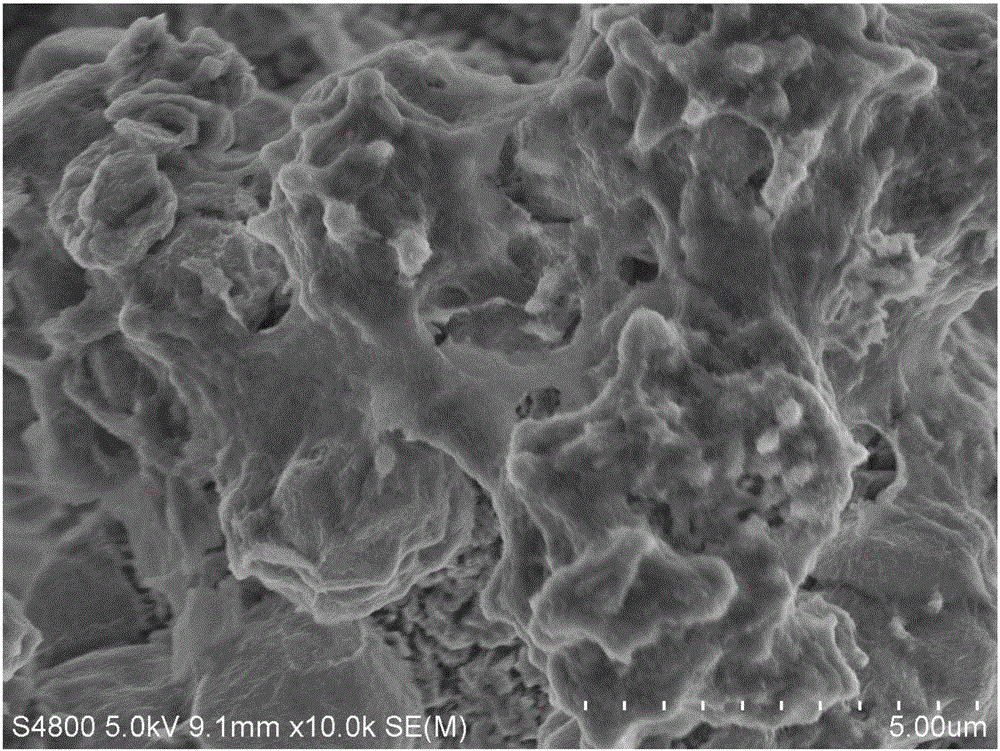

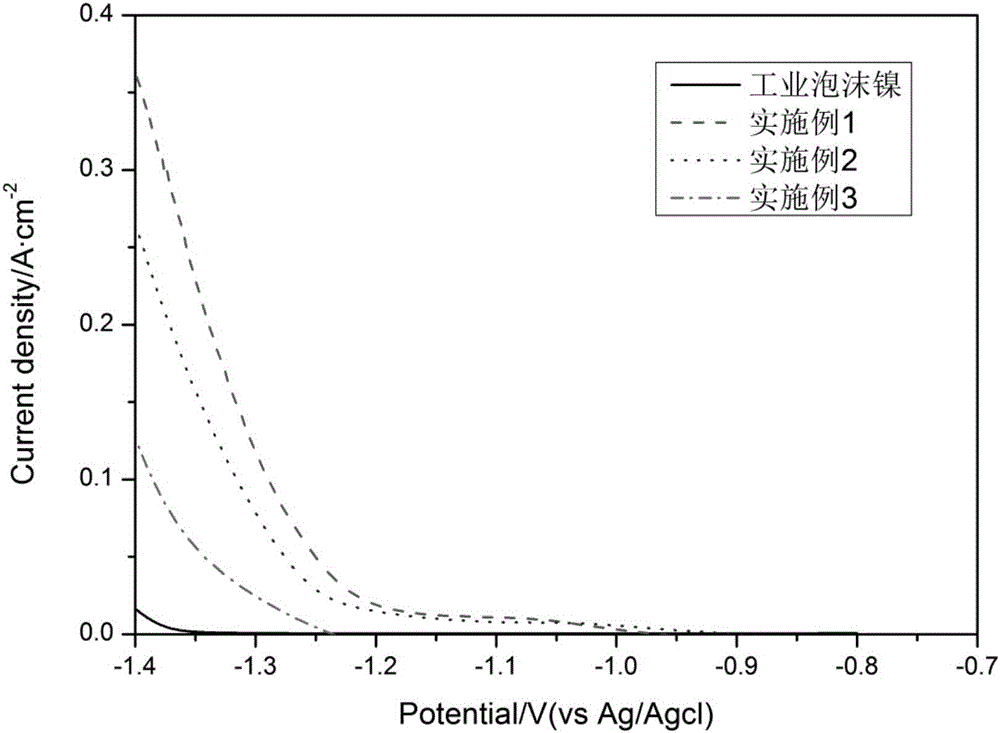

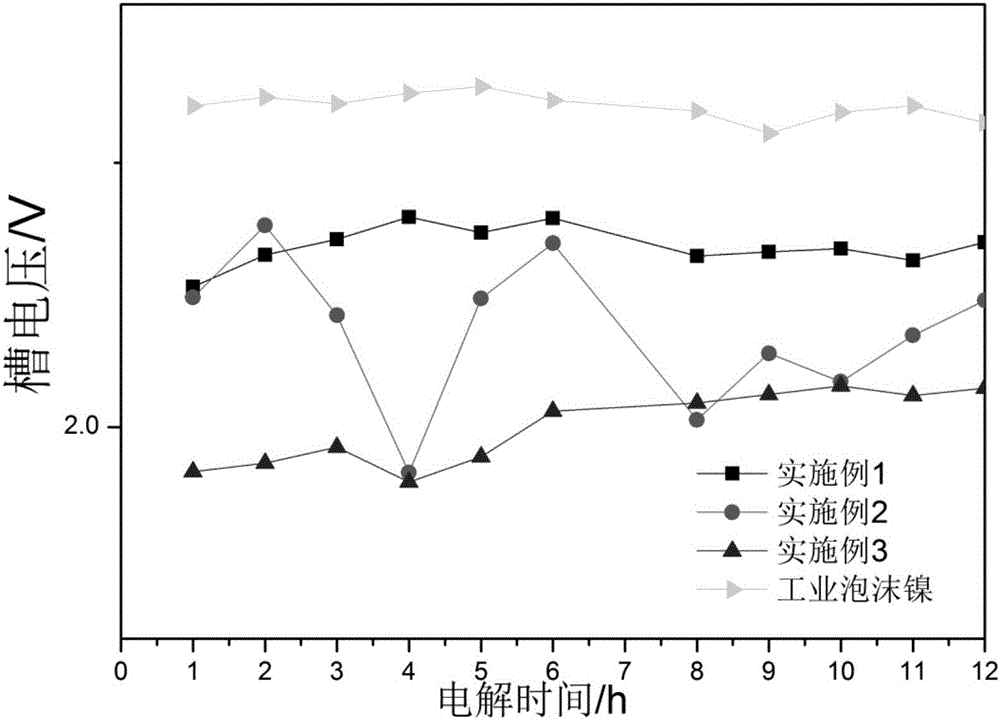

A hydrogen evolution electrode, high-efficiency technology, applied in the direction of electrode, electrode shape/type, electrolysis process, etc., can solve the problems of high energy consumption in the preparation of hydrogen evolution electrodes, difficulties in industrial production, etc., to increase the real surface area and specific surface area, and improve catalytic hydrogen evolution Activity and stability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Pretreatment of conductive substrate

[0033] The substrate is nickel foam, and the nickel foam is cut to a size of 2.5cm*4.0cm, and rinsed with deionized water for later use. Firstly, electrolytic degreasing was performed on the tailored nickel foam; the nickel foam was used as the cathode and the anode successively, placed in the electrolyte, and electrolyzed for 15 minutes respectively, with a current density of 40mA cm -2 . The electrolyte formula is: sodium hydroxide 40g L -1 , sodium carbonate 25g·L -1 , sodium phosphate 25g·L -1 . After degreasing treatment, the electrode was rinsed repeatedly with deionized water until the pH value was neutral. Afterwards, pickling the foamed nickel after electrolytic degreasing: put it into the acid solution for 30 minutes, then rinse it with deionized water until the pH is neutral, and set it aside. The pickling liquid configuration method is to mix concentrated hydrochloric acid and deionized water according to the ...

Embodiment 2

[0047] Step (1) is the same as step (1) in Example 1;

[0048] (2) Plasma spraying Ni-Mo-Al particles

[0049] Nickel powder with a particle size of 10 μm, Mo particles with a particle size of 60 nm, and Al with a particle size of 200 μm are uniformly mixed in a mass ratio of 5:1:1. The metal particle mixing process is as follows: after mixing nano-Ni particles, Mo particles and Al particles in a ratio of 5:1:1, put them into a ball mill and grind for 3 hours.

[0050] After taking it out, use the method of plasma spraying, under the protection of shielding gas, evenly spray on the surface of foamed nickel.

[0051] (3) The electrode after plasma spraying is treated in a constant temperature water bath of potassium hydroxide solution to remove Al

[0052] The nickel foam finished by plasma spraying was immersed in a KOH solution with a mass fraction of 25%, and treated in a water bath at a constant temperature for 24 hours. The temperature of the water bath was set at 60°C....

Embodiment 3

[0059] (1) The base is nickel mesh, cut to a size of 2.5cm*4.0cm, rinsed with deionized water and set aside. Put the nickel net into the constant temperature water bath to raise the temperature to 100°C, then put the machined nickel net into it, treat it at constant temperature for 1 hour, and then rinse it with deionized water; then pickle the nickel net: put Soak in acid solution for 30 minutes, then rinse with deionized water until the pH is neutral, and set aside.

[0060] (2) Plasma spraying Ni-Mo-Al particles

[0061] Nickel powder with a particle size of 200 μm, Mo particles with a particle size of 5 nm, and Al with a particle size of 10 μm are uniformly mixed in a mass ratio of 9:1:1. The mixing process of metal particles is as follows: after mixing nano-Ni particles, Mo particles and Al particles in a ratio of 9:1:1, put them into a ball mill and grind for 3 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com