Preparation of an ito-based carboxylated multi-walled carbon nanotube-modified electrode and a method for measuring uric acid using the electrode

A technology of multi-walled carbon nanotubes and modified electrodes, which is applied in the field of electrochemical analysis, can solve the problems of cumbersome sample processing, limited scope of use, and high price in chromatography, and achieve high activity of surface atoms, low cost of determination, and simple method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

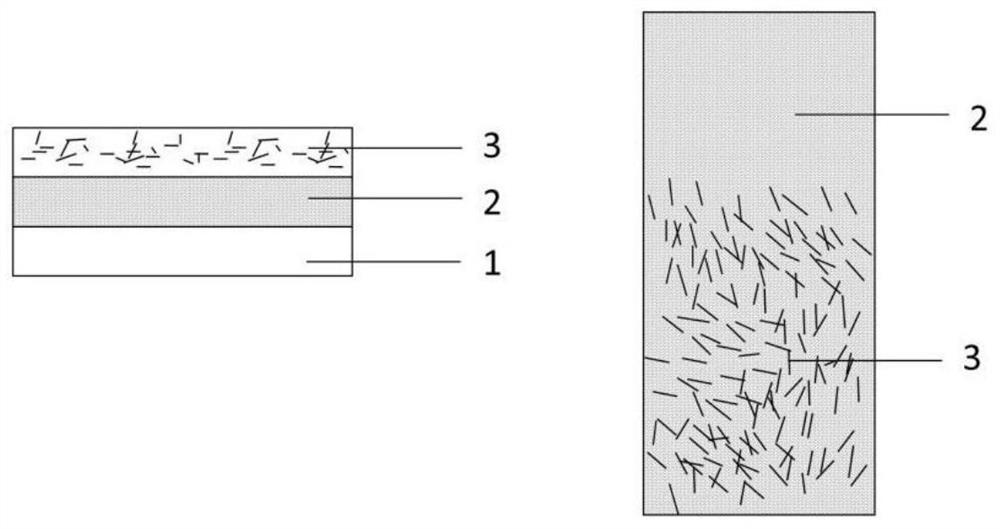

[0017] The preparation method of the carboxylated multi-walled carbon nanotube modified electrode based on ITO in the following examples is:

[0018] Cleaning of ITO glass surface. The ITO glass was cut into 1 cm × 4 cm, ultrasonically cleaned in deionized water for 30 min, then ultrasonically cleaned in acetone for 30 min, and finally ultrasonically cleaned in absolute ethanol for 30 min. Blow dry with nitrogen for later use.

[0019] The polymer layer self-assembly on the surface of ITO glass, the specific steps are as follows:

[0020] (1) Put the ITO glass conductive layer into an ultraviolet ozone cleaner for surface hydroxylation for 30 minutes.

[0021] (2) Soak the ITO glass in 1mg / mL PDDA solution for 3min, take it out, wash the excess solution on the surface with deionized water, blow dry with nitrogen, then soak it in 1mg / mLPSS solution for 3min, take it out and use deionized water The excess solution on the surface was washed with water, and blown dry with nitro...

Embodiment 2

[0028] Sample: 55 μmol / L uric acid standard solution.

[0029] test methods:

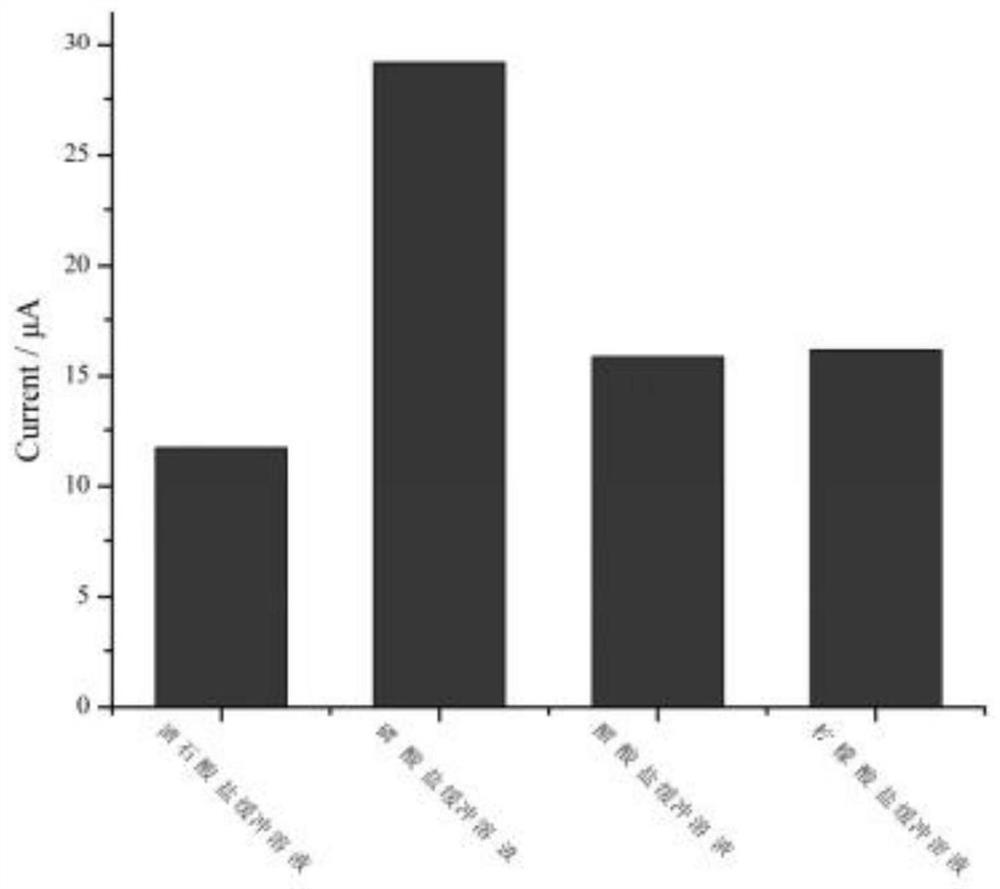

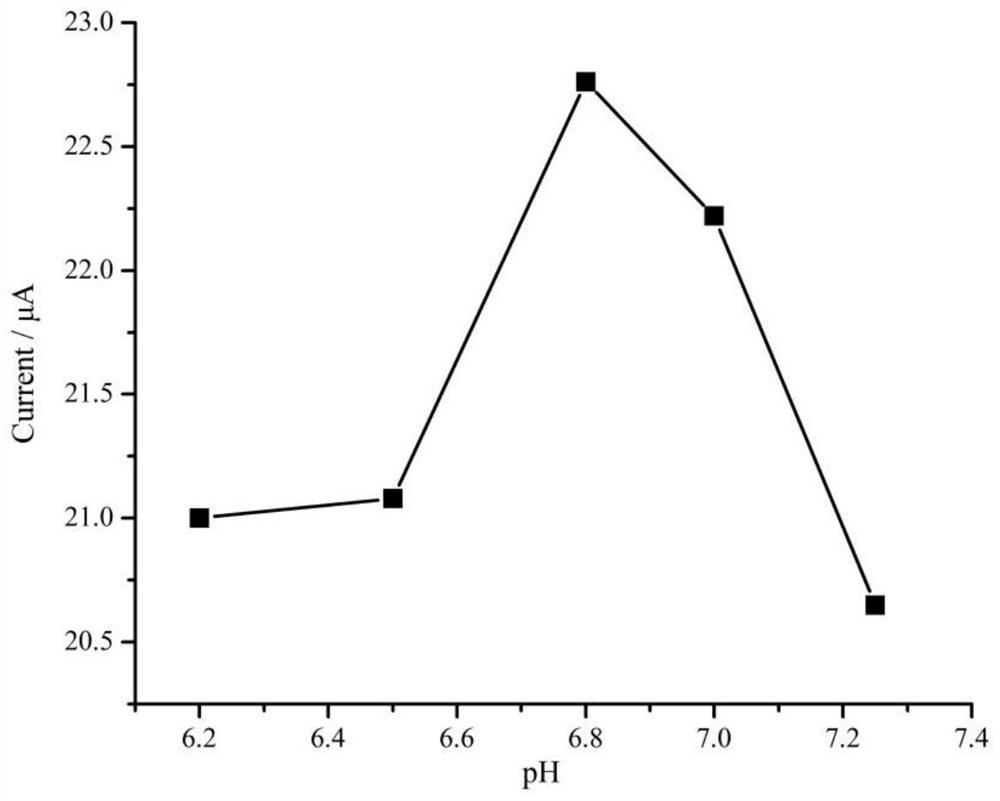

[0030] Using the three-electrode system prepared in Example 1: the ITO-based carboxylated multi-walled carbon nanotube modified electrode is the working electrode, the Ag / AgCl electrode is the reference electrode, and the platinum wire is the auxiliary electrode, with a pH of 6.8 at 0.05mol / L Sodium dihydrogen phosphate-disodium hydrogen phosphate solution is used as the supporting electrolyte, and the differential pulse voltammetry is used for electrical measurement, and the differential pulse voltammetry curve of uric acid in the range of -0.1 to 0.8V is recorded, and the standard curve method is used for quantification analyze.

[0031] The experiment was measured 10 times in parallel, and the average value of the oxidation peak current was 7.54×10 -5 A, substituted into the linear regression equation y=2.26741×10 -5 +9.81313×10 -7 x calculates that the average content of uric acid in the mea...

Embodiment 3

[0033] Sample: 20 μmol / L uric acid standard solution.

[0034] test methods:

[0035] A three-electrode system is adopted: the ITO-based carboxylated multi-walled carbon nanotube modified electrode is used as the working electrode, the Ag / AgCl electrode is used as the reference electrode, and the platinum wire is used as the auxiliary electrode. 0.05 mol / L sodium dihydrogen phosphate with pH 6.8- Disodium hydrogen phosphate solution was used as the supporting electrolyte. Differential pulse voltammetry was used for electrical measurement. The differential pulse voltammetry curve of uric acid in the range of -0.1-0.8V was recorded, and the standard curve method was used for quantitative analysis.

[0036] The experiment was measured 10 times in parallel, and the average value of the oxidation peak current was 4.378×10 -5 A, substituted into the linear regression equation y=2.26741×10 -5 +9.81313×10 -7 x calculates that the average content of uric acid in the measured solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com