Preparation method of anode material for efficiently degrading phenol wastewater

A technology for the degradation of anode materials and wastewater, applied in electrolytic inorganic material coatings, electrolytic coatings, chemical instruments and methods, etc., can solve the problems of surface peeling of substrates, weak binding force, and failure to meet actual production requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

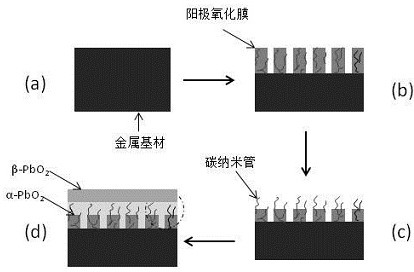

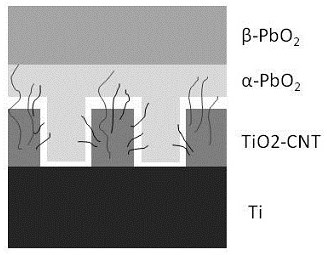

[0062] An anode material for high-efficiency phenol wastewater degradation, which is prepared by the following method:

[0063] (1) Provide a titanium or titanium alloy metal substrate, and pretreat the metal substrate. The pretreatment includes mechanical polishing-alkaline washing-acid cleaning, and the polishing is followed by using 300 mesh and 800 mesh sandpaper Polished, then rinsed with deionized water, the alkaline washing is a mixed aqueous solution of 10g / L sodium carbonate, 10g / L trisodium phosphate, 10g / L sodium silicate, 1g / L octylphenol polyoxyethylene ether, temperature 40 o C, time 10min,

[0064] The pickling is a composite pickling solution of 2wt.% oxalic acid and 1wt.% hydrochloric acid, and the pickling temperature is 50 o C, time 30min, use deionized washing after pickling.

[0065] (2) Configure an anodizing solution containing carbon nanotubes. The anodizing solution is 50ml of an aqueous solution of 4g / L ammonium fluoride, 300ml ethylene glycol, and 0.15wt.% ...

Embodiment 2

[0074] An anode material for high-efficiency phenol wastewater degradation, the material is prepared by the following method:

[0075] (1) Provide a titanium or titanium alloy metal substrate, and pretreat the metal substrate. The pretreatment includes mechanical polishing-alkaline washing-acid cleaning, and the polishing is followed by using 300 mesh and 800 mesh sandpaper Polished, then rinsed with deionized water, the alkaline washing is a mixed aqueous solution of 15g / L sodium carbonate, 15g / L trisodium phosphate, 15g / L sodium silicate, 1.5g / L octylphenol polyoxyethylene ether, temperature 15 o C, time 12.5min,

[0076] The pickling is a compound pickling solution of 2.5wt. oxalic acid and 1.25wt.% hydrochloric acid, and the pickling temperature is 55 o C, time 35min, use deionized washing after pickling.

[0077] (2) Configure an anodizing solution containing carbon nanotubes. The anodizing solution is 55ml of an aqueous solution of 4.5g / L ammonium fluoride, 400ml ethylene glyc...

Embodiment 3

[0086] An anode material for high-efficiency phenol wastewater degradation, the material is prepared by the following method:

[0087] (1) Provide a titanium or titanium alloy metal substrate, and pretreat the metal substrate. The pretreatment includes mechanical polishing-alkaline washing-acid cleaning, and the polishing is followed by using 300 mesh and 800 mesh sandpaper Polished, then rinsed with deionized water, the alkaline washing is a mixed aqueous solution of 20g / L sodium carbonate, 20g / L trisodium phosphate, 20g / L sodium silicate, 2g / L octylphenol polyoxyethylene ether, temperature 50 o C, time 15min,

[0088] The pickling is a composite pickling solution of 3wt. oxalic acid and 1.5wt.% hydrochloric acid, and the pickling temperature is 60 o C, time 40min, use deionized washing after pickling.

[0089] (2) Configure an anodizing solution containing carbon nanotubes. The anodizing solution is 60ml of an aqueous solution of 5g / L ammonium fluoride, 300-500ml ethylene glycol, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com