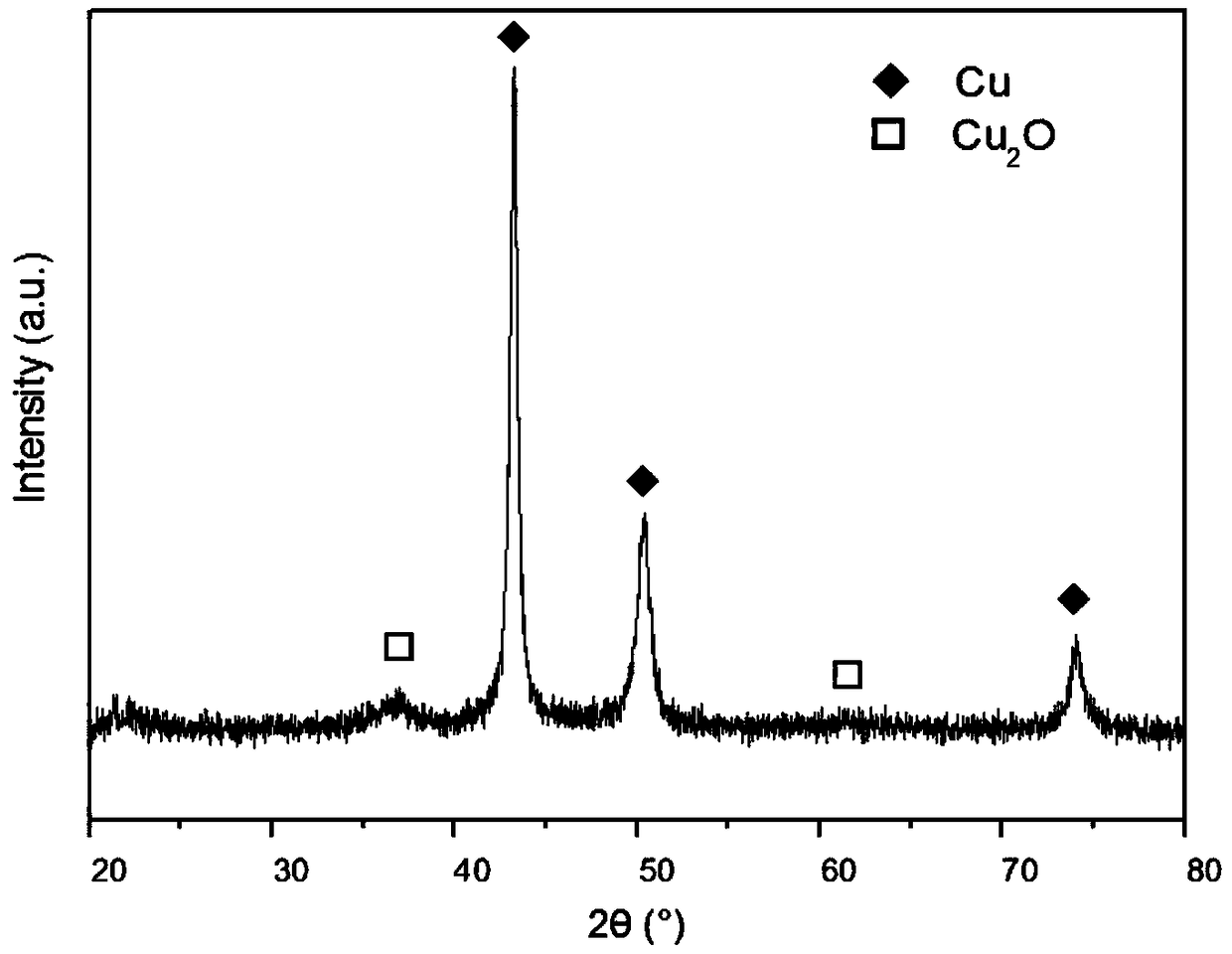

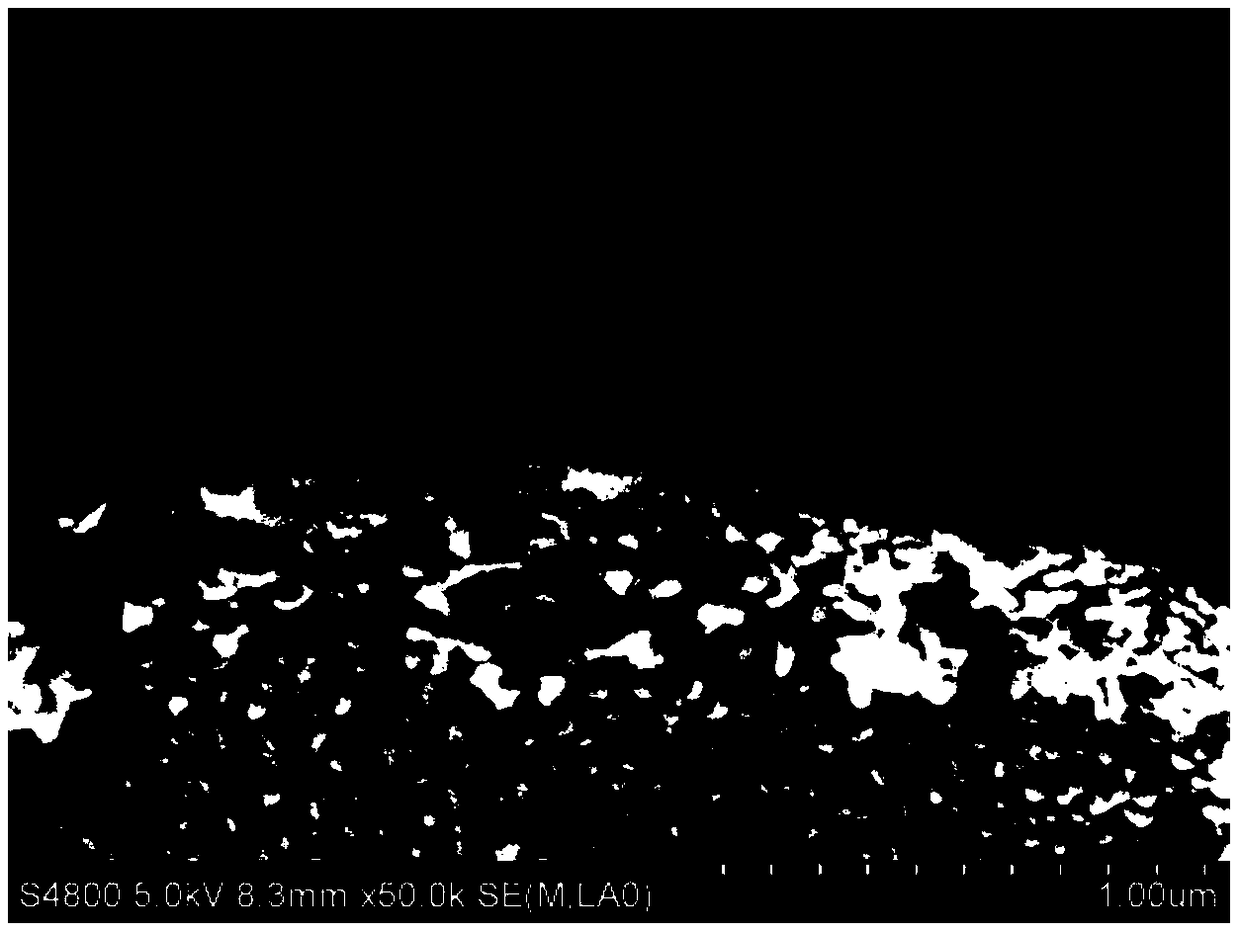

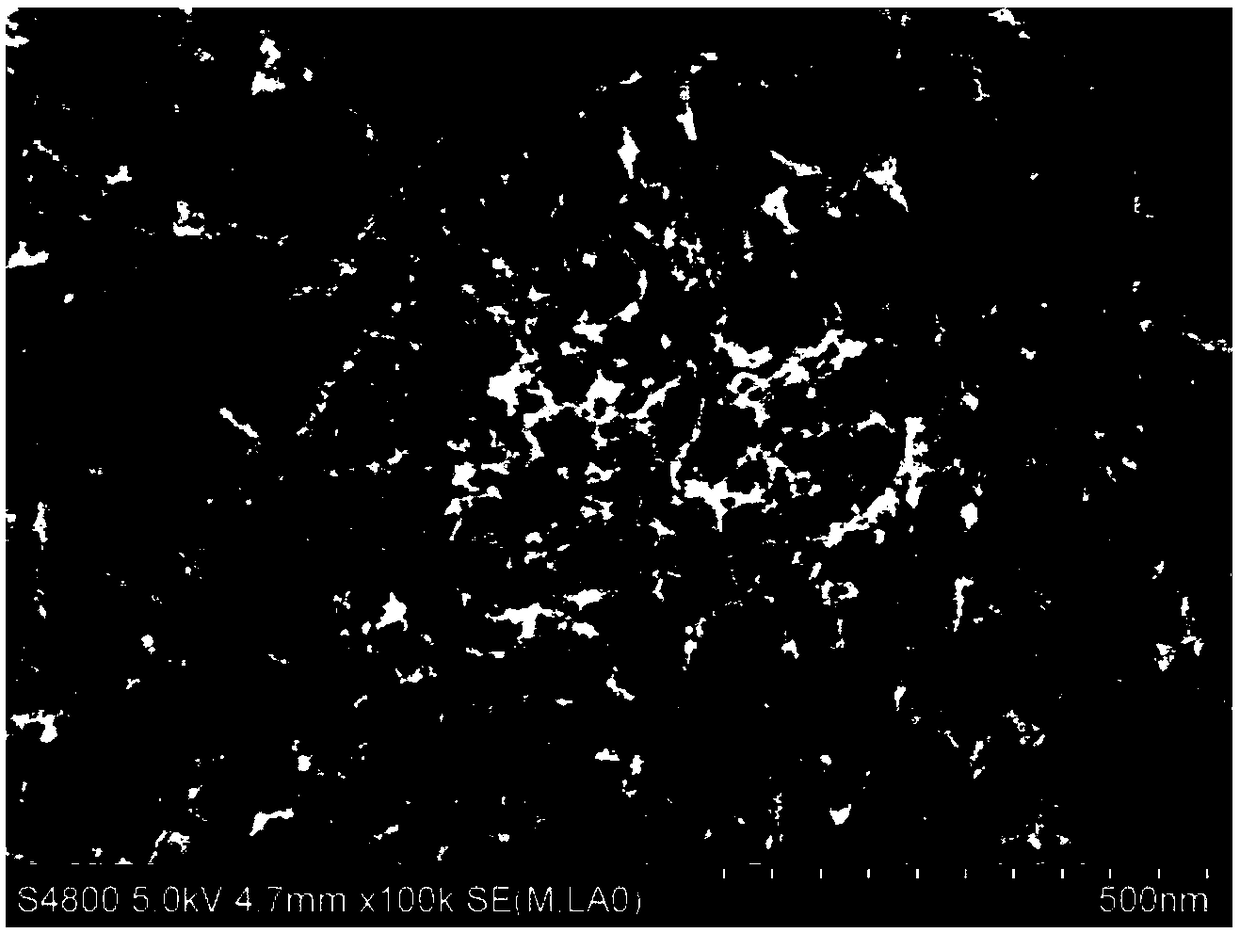

Three-dimensional nanoporous copper/one-dimensional cuprous oxide nanowire network-type lithium-ion battery negative electrode and its one-step preparation method

A lithium-ion battery, cuprous oxide technology, applied in the direction of battery electrodes, nanotechnology, nanotechnology, etc., can solve the problems of reduced specific capacity, complex structure, difficulty in meeting the energy density requirements of lithium-ion batteries, etc., to achieve faster formation speed, Achieving the effect of controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, the preparation method of the negative electrode of the three-dimensional nanoporous copper / one-dimensional cuprous oxide nanowire network type lithium-ion battery is as follows:

[0033] Copper-manganese alloy blocks with 50% atomic percentage of copper and manganese are wire-cut into copper-manganese alloy sheets with a thickness of 0.4mm with a wire cutting machine, and the copper-manganese alloy sheets are successively sanded with 380 mesh, 800 mesh, 1200 mesh, and 2000 mesh water sandpaper. The surface of the alloy sheet was polished, and then polished with a diamond polishing paste with a particle size of 0.5 μm. The polished copper-manganese alloy sheet was placed in an ultrasonic cleaner, ultrasonically cleaned with absolute ethanol at 100W for 2 minutes, taken out and left to air naturally. Dry.

[0034] With the copper-manganese alloy sheet treated above as the working electrode, the saturated calomel electrode as the reference electrode, and...

Embodiment 2

[0039] In this embodiment, the preparation method of the negative electrode of the three-dimensional nanoporous copper / one-dimensional cuprous oxide nanowire network type lithium-ion battery is as follows:

[0040] A copper-manganese alloy block with a copper atomic percentage of 10% and a manganese atomic percentage of 90% is wire-cut into copper-manganese alloy sheets with a thickness of 0.1mm with a wire cutting machine, and water of 380 mesh, 800 mesh, 1200 mesh, and 2000 mesh is sequentially used The surface of the copper-manganese alloy sheet is polished with sandpaper, and then polished with a diamond polishing paste with a particle size of 0.5 μm. The polished copper-manganese alloy sheet is placed in an ultrasonic cleaner, and ultrasonically cleaned with absolute ethanol at 100W for 3 minutes. Take it out and let it dry naturally.

[0041] With the copper-manganese alloy sheet treated above as the working electrode, the saturated calomel electrode as the reference ele...

Embodiment 3

[0045] In this embodiment, the preparation method of the negative electrode of the three-dimensional nanoporous copper / one-dimensional cuprous oxide nanowire network type lithium-ion battery is as follows:

[0046] A copper-manganese alloy block with a copper atomic percentage of 80% and a manganese atomic percentage of 20% is cut into copper-manganese alloy sheets with a thickness of 0.6mm by a wire cutting machine. The surface of the copper-manganese alloy sheet is polished with sandpaper, and then polished with a diamond polishing paste with a particle size of 0.5 μm. The polished copper-manganese alloy sheet is placed in an ultrasonic cleaner, and ultrasonically cleaned with absolute ethanol at 100W for 5 minutes. Take it out and let it dry naturally.

[0047] With the copper-manganese alloy sheet treated above as the working electrode, the saturated calomel electrode as the reference electrode, and the platinum electrode as the auxiliary electrode, the working electrode, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com