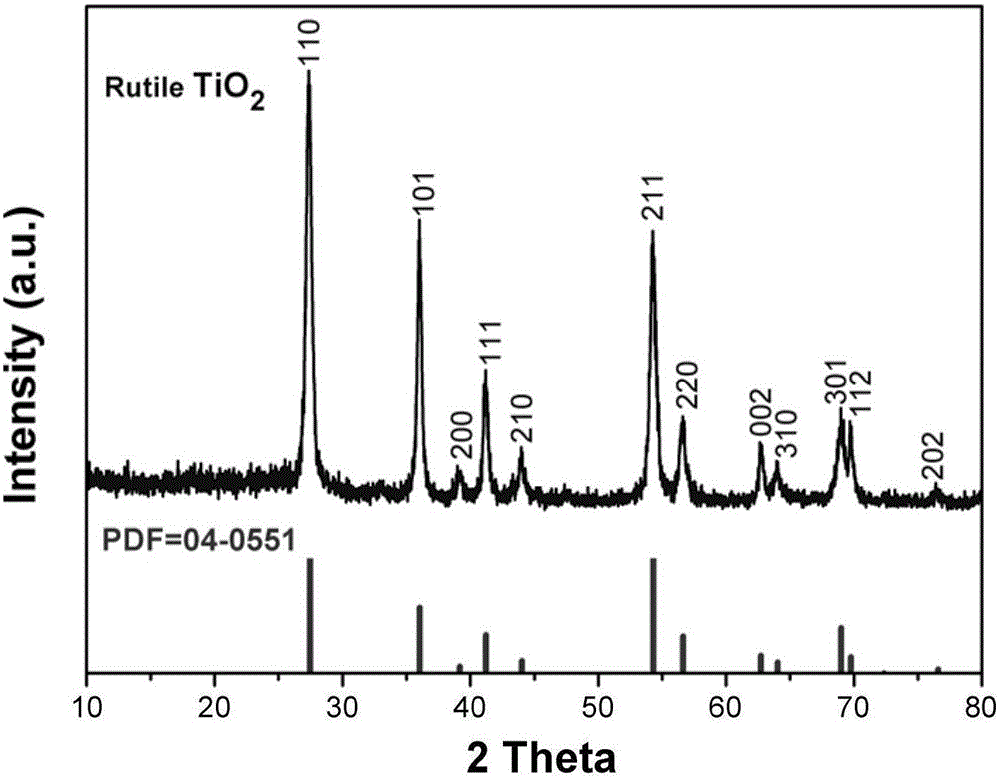

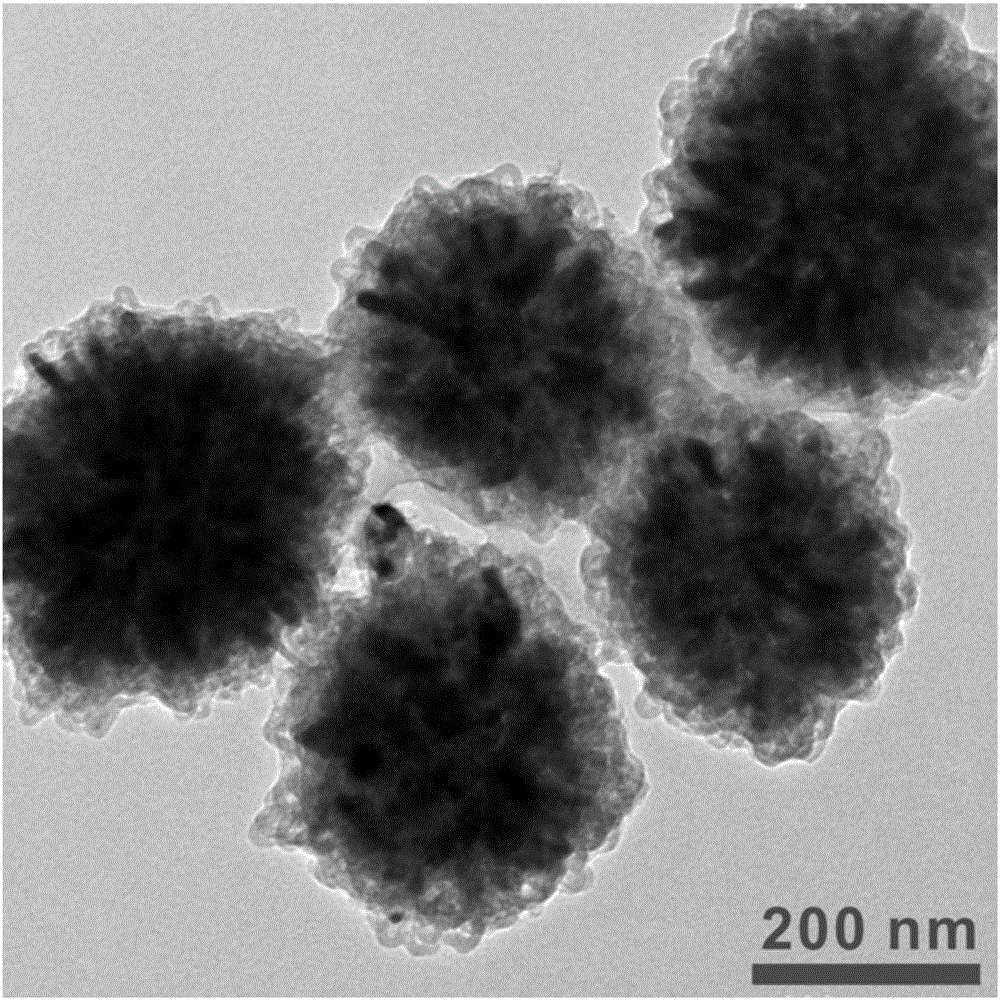

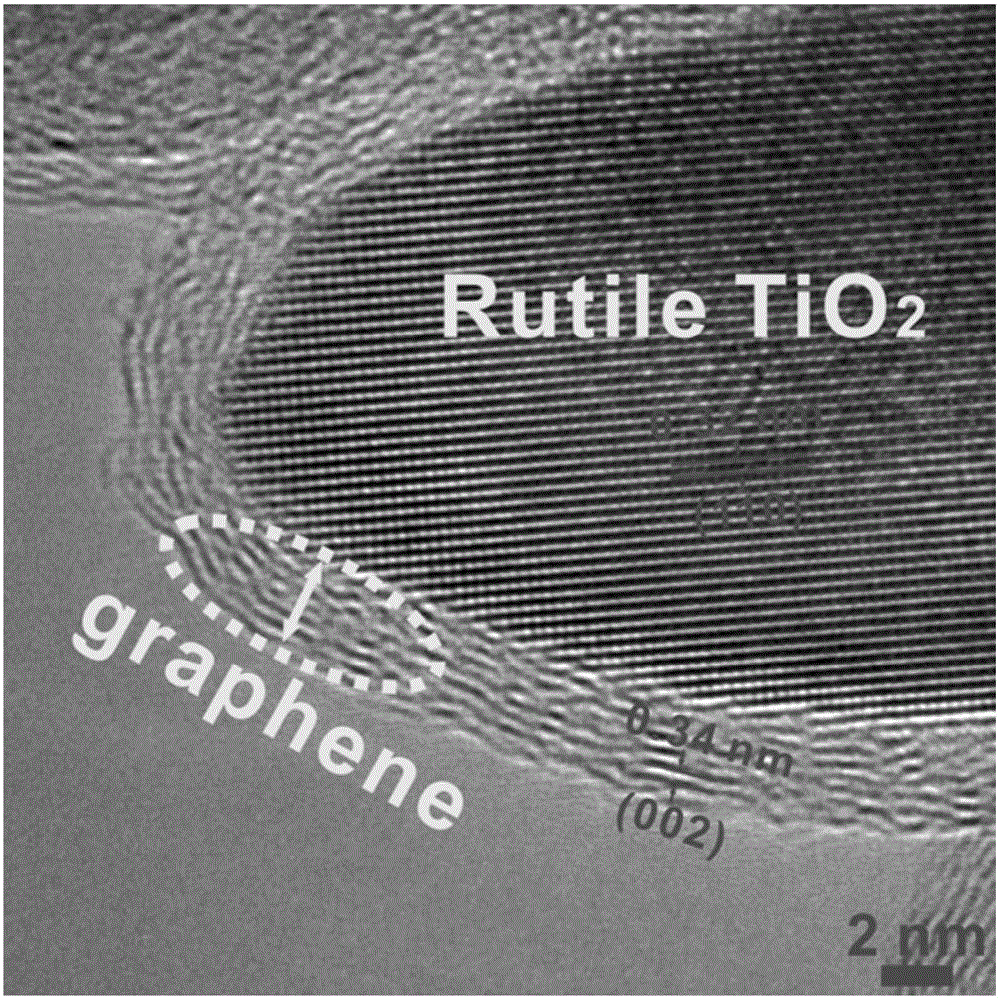

Method for controlling morphology of graphene coated nano-titanium dioxide, product prepared by the method and application of the method

A nano-titanium dioxide, graphene coating technology, applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of reducing the performance of lithium storage and sodium storage, complicated experimental steps, and limiting long-term development, etc. Achieve the effect of high capacity, low cost and high application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042]Add 0.58g of cetyltrimethylammonium bromide (CTAB) into a mixed solvent composed of 60ml of n-hexane and 10ml of n-pentanol, seal it with a parafilm, and dissolve it with magnetic stirring in a water bath at 60°C. After the uniform colorless solution, add 20 mg of carbon quantum dots, stir for 2-5 minutes to form a uniform bright yellow solution, and then drop into 1.0 ml of titanium chloride solution (15% titanium trichloride dilute hydrochloric acid solution) to form a brownish purple uniform solution , continue to stir for 2-5min, transfer all the solution into the reaction kettle, and carry out solvothermal reaction, the reaction temperature is 200°C, the reaction time is 6h, and naturally cool to room temperature after the reaction. A yellow homogeneous solution was obtained, and the excess organic solvent was evaporated with a rotary evaporator, and then the product was dried in a vacuum oven at 100° C. for 24 hours to obtain a yellow paste-like substance. The yell...

Embodiment 2

[0044] Embodiment 2 (without adding carbon quantum dots)

[0045] Add 0.58g of cetyltrimethylammonium bromide (CTAB) into a mixed solvent composed of 60ml of n-hexane and 10ml of n-pentanol, seal it with a parafilm, and dissolve it with magnetic stirring in a water bath at 60°C. After the uniform colorless solution, drop 1.0ml of titanium chloride solution (15% titanium trichloride dilute hydrochloric acid solution) to form a uniform solution of brownish purple, continue to stir for 2-5min, transfer all the solutions to the reaction kettle, and carry out the solvent Thermal reaction, the reaction temperature is 200°C, the reaction time is 6h, and naturally cooled to room temperature after the reaction. A white homogeneous solution was obtained, and the excess organic solvent was evaporated with a rotary evaporator, and then the product was dried in a vacuum oven at 100° C. for 24 hours to obtain a white paste-like substance. The white paste substance was calcined at 800°C for...

Embodiment 3

[0046] Embodiment 3 (adding a small amount of carbon quantum dots)

[0047] Add 0.58g of cetyltrimethylammonium bromide (CTAB) into a mixed solvent composed of 60ml of n-hexane and 10ml of n-pentanol, seal it with a parafilm, and dissolve it with magnetic stirring in a water bath at 60°C. After the uniform colorless solution, add 10 mg of carbon quantum dots and stir for 2-5 minutes to form a uniform bright yellow solution, then drop in 1.0 ml of titanium chloride solution (15% titanium trichloride dilute hydrochloric acid solution) to form a brownish purple uniform solution , continue to stir for 2-5min, transfer all the solution into the reaction kettle, and carry out solvothermal reaction, the reaction temperature is 200°C, the reaction time is 6h, and naturally cool to room temperature after the reaction. A yellow homogeneous solution was obtained, and the excess organic solvent was evaporated with a rotary evaporator, and then the product was dried in a vacuum oven at 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com