Preparing technology of high-quality apple jam

A preparation process, applesauce technology, applied in the field of food processing, can solve the problems of flavor loss, loss of nutrients, neglect of enzymatic browning of fruit pulp, etc., and achieve inhibition of enzymatic browning, high coupling efficiency, and fast cooling speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Raw material selection and processing: select fresh and ripe Red Fuji apples, which are required to be free from mildew, rot, insects, qualified pesticide residues, and sugar content greater than 12 Brix, and fully wash the apples;

[0028] (2) Cutting the petals: Cut each apple into four petals to facilitate the subsequent integrated treatment of crushing and killing enzymes;

[0029] (3) Integrated coupling treatment of crushing and killing enzymes: During the process of apple crushing, steam with a pressure of about 0.15 MPa is sprayed on the crushed apples, so that the temperature of the pulp rises rapidly to 86°C within 2 minutes, and Hold for 30 seconds;

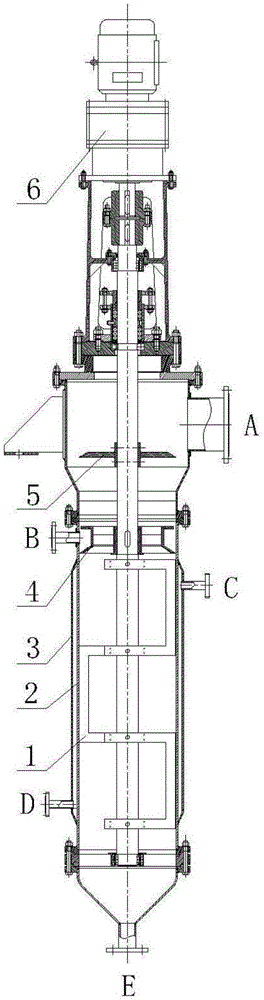

[0030] (4) Ultra-fast cooling: pump the fruit pulp after steam heating to kill enzymes and crush it to a centrifugal scraper type film vacuum evaporator, so that the fruit pulp descends in a film shape, and a frozen brine is provided in the jacket of the evaporator, wherein The vacuum degree is 0.092MPa, th...

Embodiment 2

[0038] (1) Raw material selection and processing: select fresh and ripe Red Fuji apples, which are required to be free from mildew, rot, insects, qualified pesticide residues, and sugar content greater than 12 Brix, and fully wash the apples;

[0039] (2) Cutting petals: cut each apple into six petals, so as to facilitate the subsequent integrated treatment of crushing and killing enzymes;

[0040] (3) Integrated coupling treatment of crushing and killing enzymes: During the crushing process of apples, steam with a pressure of about 0.20 MPa is sprayed on the crushed apples, so that the temperature of the pulp rises rapidly to 90°C within 1 minute, and Hold for 18 seconds;

[0041] (4) Ultra-fast cooling: pump the fruit pulp after steam heating to kill enzymes and crush it to a centrifugal scraper type film vacuum evaporator, so that the fruit pulp descends in a film shape, and a frozen brine is provided in the jacket of the evaporator, wherein The vacuum degree is 0.098MPa, ...

Embodiment 3

[0049] (1) Raw material selection and processing: select fresh and ripe Red Fuji apples, which are required to be free from mildew, rot, insects, qualified pesticide residues, and sugar content greater than 12 Brix, and fully wash the apples;

[0050] (2) Cutting petals: Cut each apple into eight petals to facilitate the subsequent integrated treatment of crushing and killing enzymes;

[0051] (3) Integrated coupling treatment of crushing and killing enzymes: During the crushing process of apples, steam with a pressure of about 0.30 MPa is sprayed on the crushed apples, so that the temperature of the pulp rises rapidly to 82°C within 1 minute, and Hold for 42 seconds;

[0052] (4) Ultra-fast cooling: pump the fruit pulp after steam heating to kill enzymes and crush it to a centrifugal scraper type film vacuum evaporator, so that the fruit pulp descends in a film shape, and a frozen brine is provided in the jacket of the evaporator, wherein The vacuum degree is 0.085MPa, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com