Composite magnetic flocculating agent with auto-catalytic degradation function and method for preparing composite magnetic flocculating agent

A composite magnetic and flocculant technology, applied in chemical instruments and methods, flocculation/sedimentation water/sewage treatment, energy wastewater treatment, etc., can solve problems such as increased treatment costs, environmental threats, waste of resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

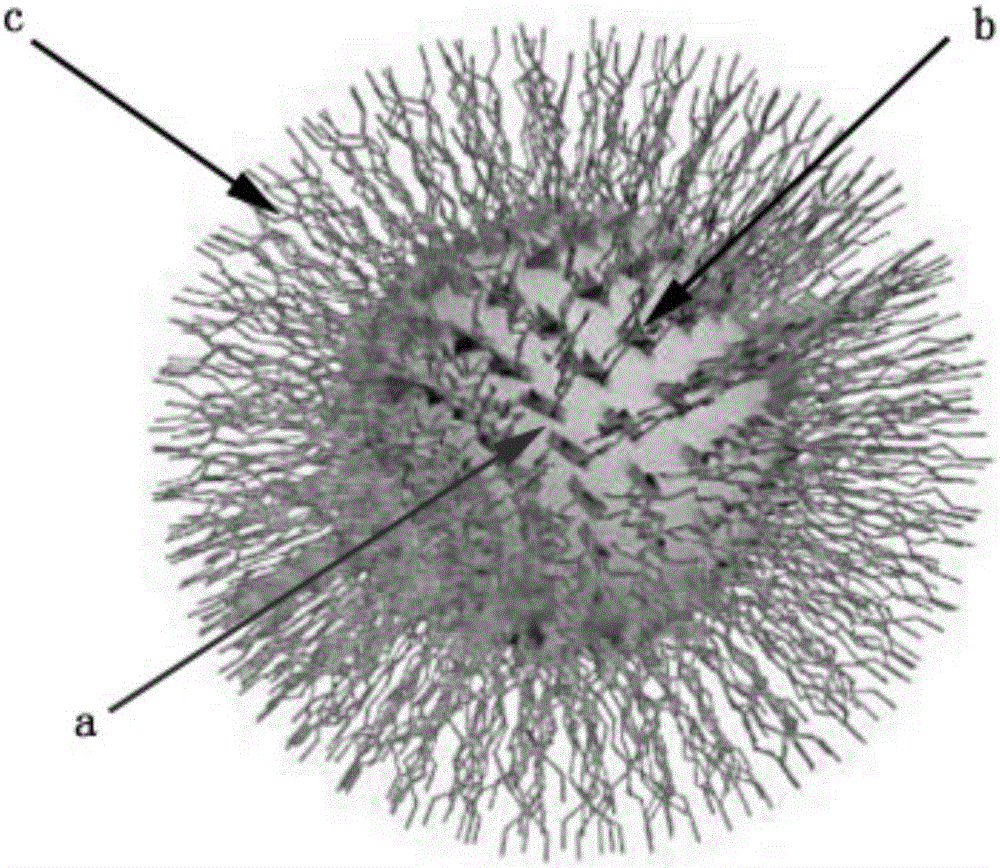

[0053] A composite magnetic flocculant with self-catalytic degradation function, which is a composite magnetic flocculant with inorganic magnetic composite particles as the core and polyacrylamide bonded on the surface of the inorganic magnetic composite particles; It is composed of three irons, a middle layer of silicon dioxide coating layer and an outer layer of titanium dioxide coating layer.

[0054] A preparation method of a composite magnetic flocculant with self-catalytic degradation function, comprising the following steps:

[0055] S1, Magnetic Fe 3 o 4 Preparation: Under nitrogen atmosphere, take ferrous iron and ferric iron and add ammonia water to prepare magnetic Fe by co-precipitation method. 3 o 4 ;

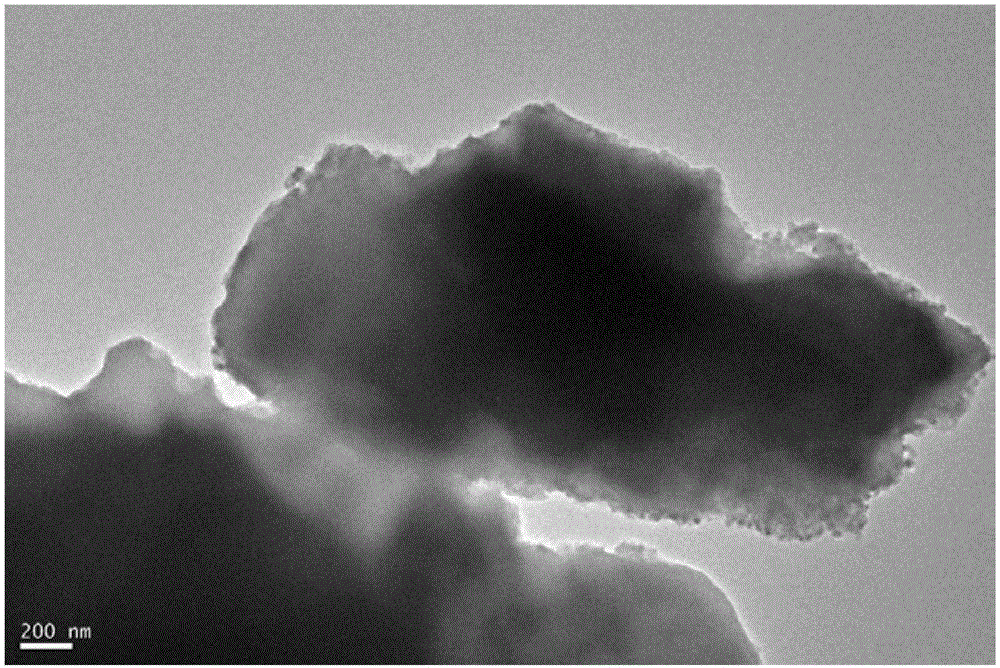

[0056] S2, SiO 2 Coated Fe 3 o 4 Preparation of magnetic composite particles: Under alkaline conditions, the magnetic Fe prepared in S1 3 o 4 Ethyl orthosilicate is added to prepare SiO 2 Coated Fe 3 o 4 Magnetic composite particles; it can avoid the ox...

Embodiment 2

[0060] A composite magnetic flocculant with self-catalytic degradation function, which is a composite magnetic flocculant with inorganic magnetic composite particles as the core and polyacrylamide bonded on the surface of the inorganic magnetic composite particles; It is composed of three irons, a middle layer of silicon dioxide coating layer and an outer layer of titanium dioxide coating layer.

[0061] A preparation method of a composite magnetic flocculant with self-catalytic degradation function, comprising the following steps:

[0062] S1, Magnetic Fe 3 o 4 The preparation comprises the following steps:

[0063] S1.1. Weigh FeCl according to the molar ratio of 0.01:0.005 3 ·6H 2 O and FeCl 2 4H 2 O was dissolved in deionized water, fed with nitrogen, heated at 25°C, and titrated with ammonia water with a mass fraction of 25%. Among them, according to the mass-volume ratio, FeCl 3 ·6H 2 O: deionized water = 0.01g: 400mL;

[0064] S1.2. When ammonia water is titrat...

Embodiment 3

[0077] A composite magnetic flocculant with self-catalytic degradation function, which is a composite magnetic flocculant with inorganic magnetic composite particles as the core and polyacrylamide bonded on the surface of the inorganic magnetic composite particles; It is composed of three irons, a middle layer of silicon dioxide coating layer and an outer layer of titanium dioxide coating layer.

[0078] A preparation method of a composite magnetic flocculant with self-catalytic degradation function, comprising the following steps:

[0079] S1, Magnetic Fe 3 o 4 The preparation comprises the following steps:

[0080] S1.1. Weigh FeCl according to the molar ratio 0.02︰0.02 3 ·6H 2 O and FeCl 2 4H 2 O was dissolved in deionized water, fed with nitrogen, heated at 35°C, and titrated with ammonia water with a mass fraction of 25%. Among them, according to the mass-volume ratio, FeCl 3 ·6H 2 O: deionized water = 0.02g: 200mL;

[0081] S1.2. When ammonia water is titrated u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com