Method for producing furfural through lignocellulose bio-refinery

A technology for lignocellulose and biorefinery, applied in the direction of organic chemistry, etc., can solve the problems of concentrated pentose polysaccharide solution foam generation, low concentration of pentose polysaccharide solution, low efficiency of dehydration and cyclization of pentose, etc. The effect of cleaner production, energy saving and emission reduction, improving the conversion rate of raw materials and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

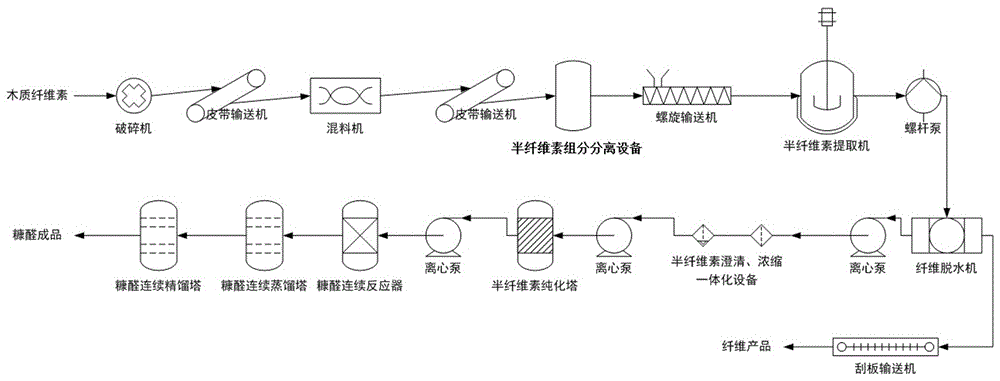

Image

Examples

Embodiment 1

[0041] A method for producing furfural by lignocellulose biorefining, comprising the following steps:

[0042] (1) Raw material pretreatment

[0043] Weigh 100 kg of corn cobs (on an absolute dry basis), the content of pentosan in the corn cobs is 38%, and the moisture content of the air-dried mass of the corn cobs is 10%, and the corn cobs are crushed into 5-10 mm particle;

[0044] (2) Mixing

[0045] The acetyl group content in corn cob is 1.2% (the weight of acetyl group accounts for the percentage of the weight of corn cob), and the acetyl group of corn cob is converted into acetic acid during the steam explosion process, so it is equivalent to 1.2% acid in the raw material, adding 50 kg of 60 ° C Water and 1.8 kg of concentrated sulfuric acid with a mass fraction of 98% and corncobs were mixed evenly in a mixer, and the water at 60 °C came from the waste steam condensed and recovered during the steam explosion process;

[0046] (3) Separation of hemicellulose componen...

Embodiment 2

[0064] A method for producing furfural by lignocellulose biorefining, comprising the following steps:

[0065] (1) Raw material pretreatment

[0066] Weigh 100 kg of crop stalks-corn stalks (on a dry basis), the corn stalks have a pentosan content of 22%, and the corn stalks have an air-dried moisture content of 6%, and use a hammer crusher to crush the corn stalks into filaments;

[0067] (2) Mixing

[0068] The acetyl content of corn stalks is 2.0% (the weight of acetyl groups accounts for the percentage of the weight of corn stalks), and the acetyl groups of corn stalks are converted into acetic acid during the steam explosion process, so it is equivalent to 2.0% acid in the raw material. Water and 0.7kg of concentrated sulfuric acid with a mass fraction of 98% and corn stalks were evenly mixed in a mixer, and the water at 60°C came from the waste steam condensed and recovered during the steam explosion process;

[0069] (3) Separation of hemicellulose components

[0070...

Embodiment 3

[0087] A method for producing furfural by lignocellulose biorefining, comprising the following steps:

[0088] (1) Raw material pretreatment

[0089] Weigh 100 kg of bagasse (in terms of absolute dryness), the content of bagasse pentosan is 27%, and the moisture content of bagasse air-dried mass is 12%, because bagasse is a by-product of the sugarcane sugar industry, during the sugar making process has been crushed, no further fragmentation is required;

[0090] (2) Mixing

[0091] The acetyl content of bagasse is 1.7% (the weight of acetyl group accounts for the percentage of corn stalk weight), and the acetyl group of bagasse is converted into acetic acid during the steam explosion process, so it is equivalent to 1.7% acid in the raw material, adding 52 kg of 60℃ Water and 0.9 kg of concentrated sulfuric acid with a mass fraction of 98% and bagasse were mixed evenly in a mixer, and the water at 60 °C came from the waste steam condensed and recovered during the steam explos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com