Lithium ion battery diaphragm coating, and preparation method and application thereof

A lithium-ion battery and separator technology, applied in coatings, battery pack components, circuits, etc., can solve problems such as internal temperature rise, battery short circuit, melting of PP layer, etc., to enhance thermal dimensional stability and improve safety. , the effect of improving heat resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

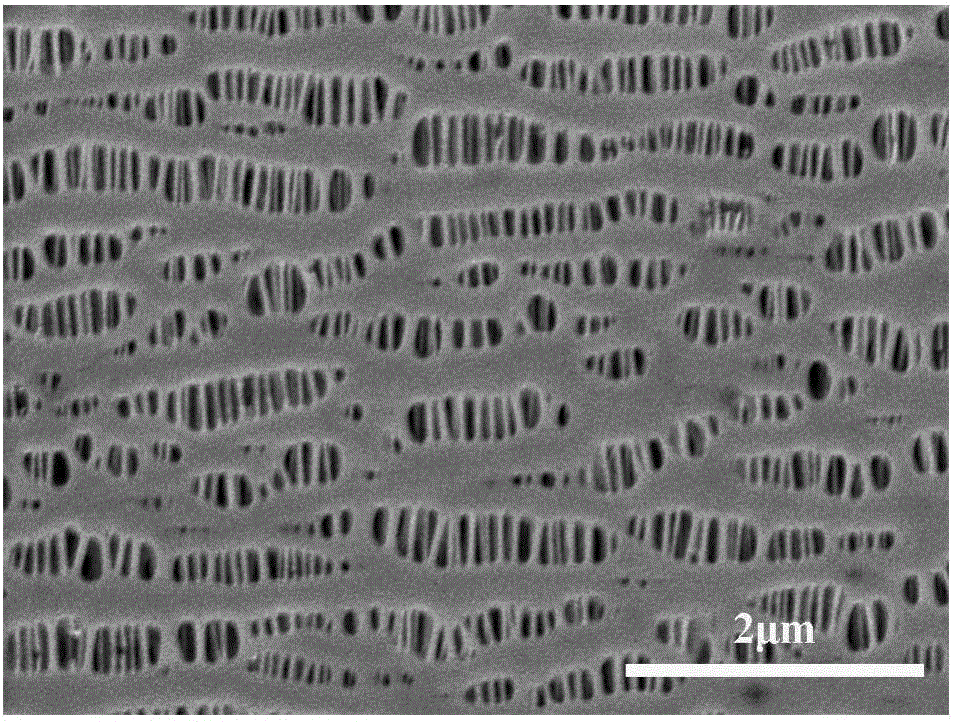

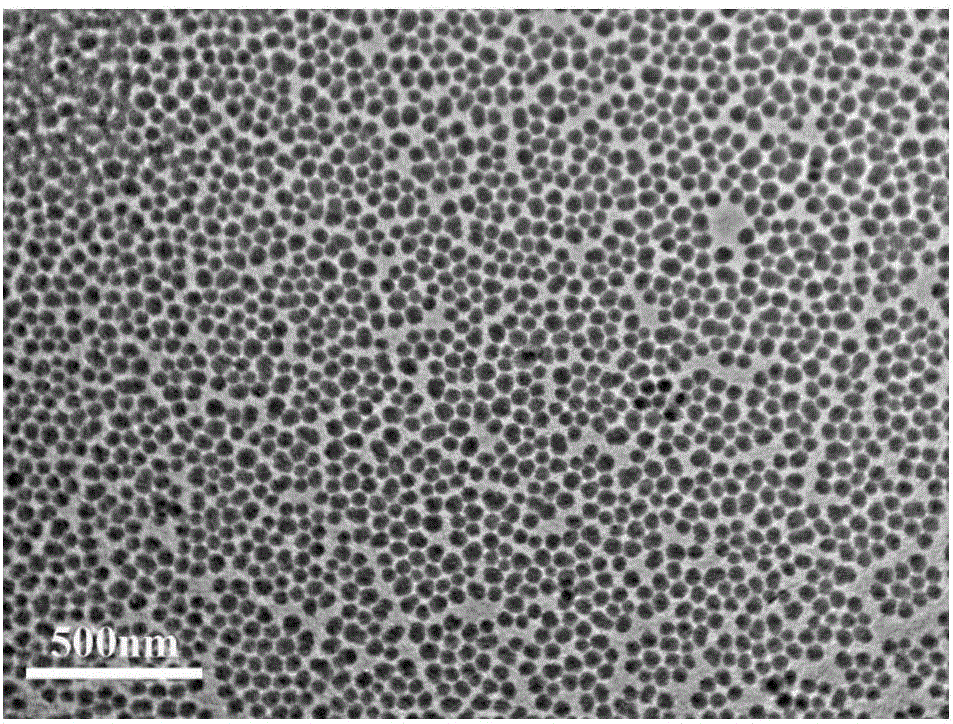

Image

Examples

Embodiment 1

[0040] 1. Preparation:

[0041] S1. Measure the ethanol of 160ml and the tetraethyl orthosilicate of 8ml respectively in the flask, extract the ammoniacal liquor of 8ml and inject in the above-mentioned flask that reaction solution is housed, with After magnetic stirring at 35°C for 24 hours, light blue nano-SiO 2Dispersions;

[0042] S2. Weigh 1.2mg of 3-(trimethoxysilyl)propyl-2-methyl-2-acrylate silane coupling agent (MPS) and dissolve it in 20ml of ethanol, and slowly drop it by titration Add it to the above light blue dispersion and continue to react for 24 hours to obtain in-situ modified SiO 2 ethanol dispersion;

[0043] S3. the resulting modified SiO 2 The ethanol dispersion was centrifuged several times with methanol and deionized water, and finally the centrifuged SiO 2 Disperse in 100ml of deionized water to prepare 0.7mg / ml SiO 2 water dispersion;

[0044] S4. To the modified SiO of step S1 2 Add 8.9ml of styrene, 1.1ml of n-butyl acrylate, 0.03g of sodiu...

Embodiment 2

[0052] The difference from Example 1 is that 8ml of styrene, 2ml of n-butyl acrylate, 0.05g of emulsifier sodium dodecylbenzenesulfonate, and 0.4g of buffering agent sodium bicarbonate are added in step S4. Emulsion of silica coated with styrene copolymerized n-butyl acrylate.

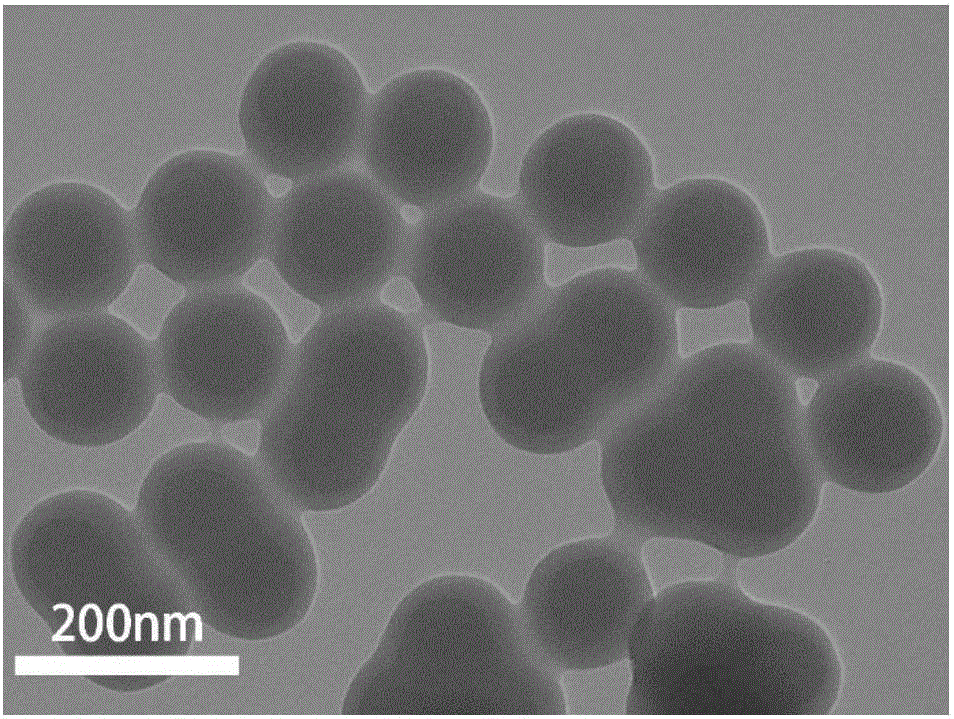

[0053] The average particle diameter of the obtained polystyrene copolymerized n-butyl acrylate-coated silica particles with a core-shell structure was determined to be 200 nm; the measured glass transition temperature of the coating was 75° C., and the thermal shutdown temperature was 75° C.

Embodiment 3

[0055] The difference from Example 1 is that 7.3ml of styrene, 2.7ml of n-butyl acrylate, 0.1g of emulsifier sodium dodecylbenzenesulfonate, and 0.8g of buffering agent sodium bicarbonate were added in step S4 to obtain a core-shell structure Polystyrene copolymer n-butyl acrylate coated silica emulsion.

[0056] The obtained polystyrene copolymerized n-butyl acrylate-coated silica particles with a core-shell structure have an average particle diameter of 300 nm, the measured glass transition temperature of the coating is 62°C, and the thermal shutdown temperature is 62°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com