Preparation method of high-purity vanadium pentoxide

A vanadium pentoxide, high-purity technology, applied in the field of high-purity vanadium pentoxide preparation, can solve the problems that the purity of vanadium pentoxide cannot meet the requirements, the adsorption rate of vanadium solution is not high, and the regeneration rate of resin is not high. Avoid the effects of low resin regeneration rate, avoid secondary pollution, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The embodiment of the present invention discloses a method for preparing high-purity vanadium pentoxide, the method comprising:

[0035] (1) dissolving solution is configured with ammonium metavanadate crude product;

[0036] (2) adding sodium hydroxide and sodium carbonate to the solution, stirring at a constant temperature and adjusting its pH value to 8.5-9.0;

[0037] (3) adding a purifying agent to the lysate after adjusting the pH value, and stirring at a constant temperature for solid-liquid separation to obtain a filtrate;

[0038] (4) ammonium chloride is added in the filtrate, and the ammonium metavanadate precipitation is obtained after standing layering, and the ammonium metavanadate precipitation obtains the ammonium metavanadate crystal after washing and dehydration;

[0039] (5) Calcining ammonium metavanadate crystals at 500-550° C. for 2-2.5 hours to obtain vanadium pentoxide.

[0040] The preparation method of high-purity vanadium pentoxide provided ...

Embodiment 1

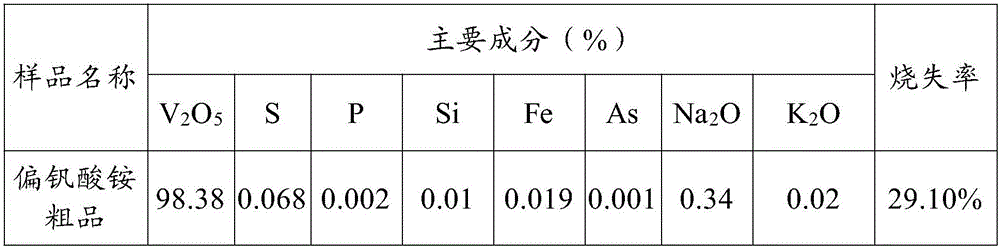

[0068] (1) Add the crude ammonium metavanadate to demineralized water, stir and dissolve at 90°C, prepare a solution, and finally measure the concentration of vanadium ions after it is completely dissolved to be 60.23g / L. Add a total of 2900kg of crude ammonium metavanadate. After testing, the main components and their contents in the added ammonium metavanadate crude product are shown in the following table:

[0069]

[0070] (2) Add industrial-grade flake sodium hydroxide and industrial-grade granular sodium carbonate to the solution, keep stirring at a constant temperature of 90°C under normal pressure, adjust the pH value to 9.0, stop adding sodium hydroxide, and stir until completely dissolved ; Now, add 300kg of sodium hydroxide and 145kg of sodium carbonate in total. During this process, keep the exhaust fan on and collect the volatilized ammonia gas, which can be used to prepare the by-product ammonium oxalate, so the whole process is environmentally friendly and po...

Embodiment 2

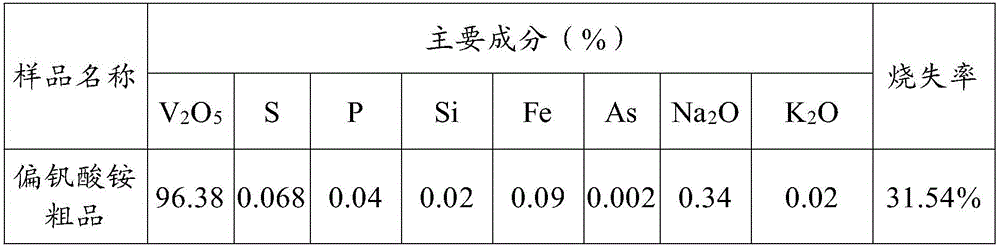

[0077] (1) Add the crude ammonium metavanadate to demineralized water, stir and dissolve at 85°C, prepare a solution, and finally measure the concentration of vanadium ions after it is completely dissolved to be 61.36g / L. Add a total of 3020.00kg of the crude ammonium metavanadate. After testing, the main components and their contents in the added ammonium metavanadate crude product are shown in the following table:

[0078]

[0079] (2) Add industrial-grade flake sodium hydroxide and industrial-grade granular sodium carbonate to the solution, keep stirring at a constant temperature of 85°C under normal pressure, adjust the pH value to 9.0, stop adding sodium hydroxide, and stir until completely dissolved ; At this point, a total of 330kg of sodium hydroxide was added, and 150kg of sodium carbonate was added. During this process, keep the exhaust fan on and collect the volatilized ammonia gas, which can be used to prepare the by-product ammonium oxalate, so the whole proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com