High refractive index inorganic oxide microsphere-organic polymer double shell phase change energy storage microcapsule and preparation method thereof

A technology of inorganic oxides and organic polymers, which is applied in the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., to achieve the effects of improving mechanical properties, improving heat insulation and temperature control performance, and making the preparation process environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]Mix 50 ml of ethanol and water evenly, and adjust the pH value to 9 with ammonia water to obtain an ethanol-water mixture; weigh 20 g of titanium dioxide microsphere powder and add it to the ethanol-water mixture, heat up to 80 ° C after ultrasonic dispersion, Insulated for 20 minutes to obtain a titanium dioxide dispersion. Take 2.5 ml of the modifier methacryloxypropyl tris(trimethylsiloxane) silane and add it to 18 mL of ethanol, mix well to obtain a modifier solution; add the modifier solution dropwise into the titanium dioxide dispersion, and then 80 DEG C continue to react for 2 hours. After the temperature drops to room temperature, the titanium dioxide powder is separated by a centrifuge, washed with ethanol, and dried to obtain titanium dioxide microsphere powder with double bonds on the surface.

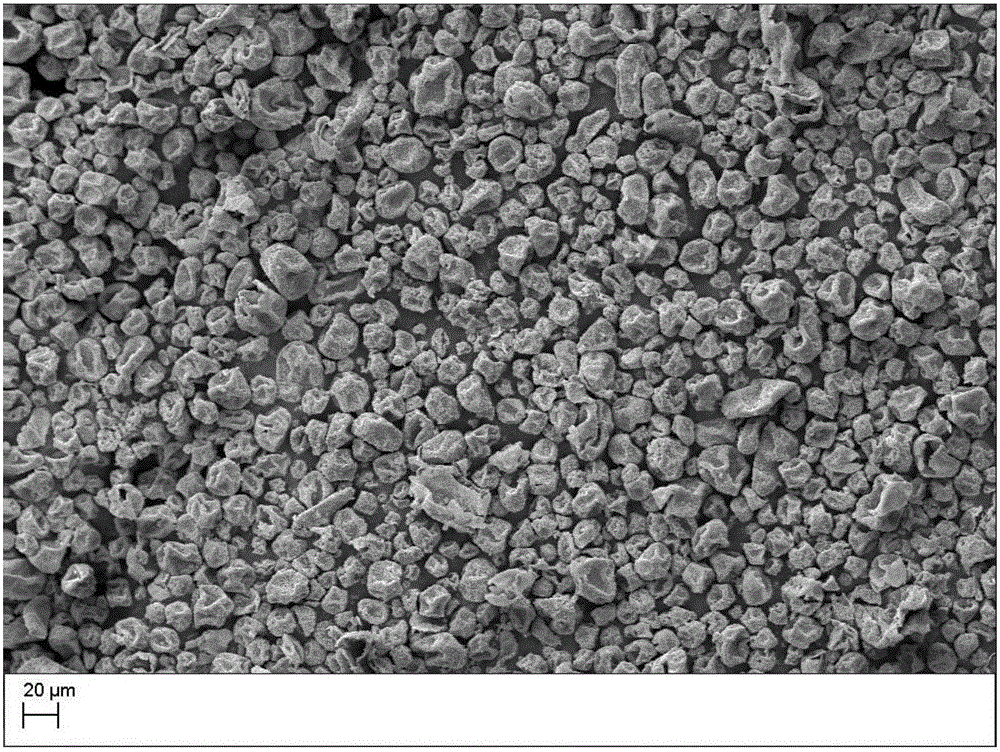

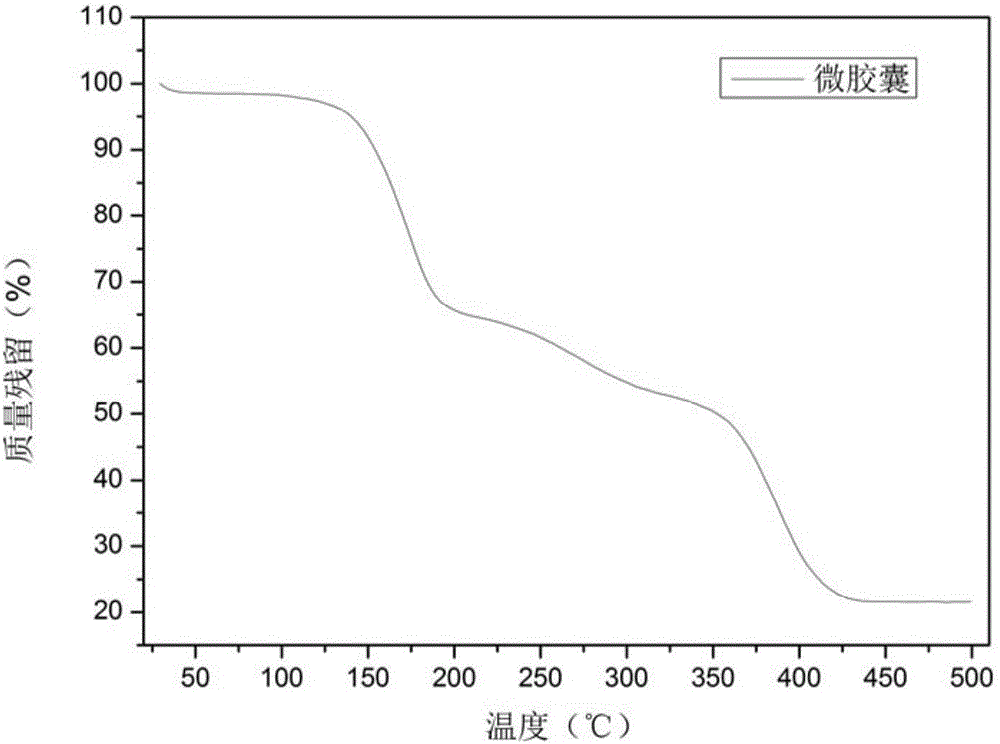

[0041] 2.3 g surface-modified titanium dioxide microsphere powder (average particle size: 200 nm) was ultrasonically dispersed in 50 mL water to obtain an aqueous ph...

Embodiment 2

[0043] The surface modification of titanium dioxide microsphere powder refers to the method in Example 1, but vinyltriethoxysilane is used as a modifier, and the concentration of the modifier solution is 5 vol%, and the rest of the conditions are the same as in Example 1.

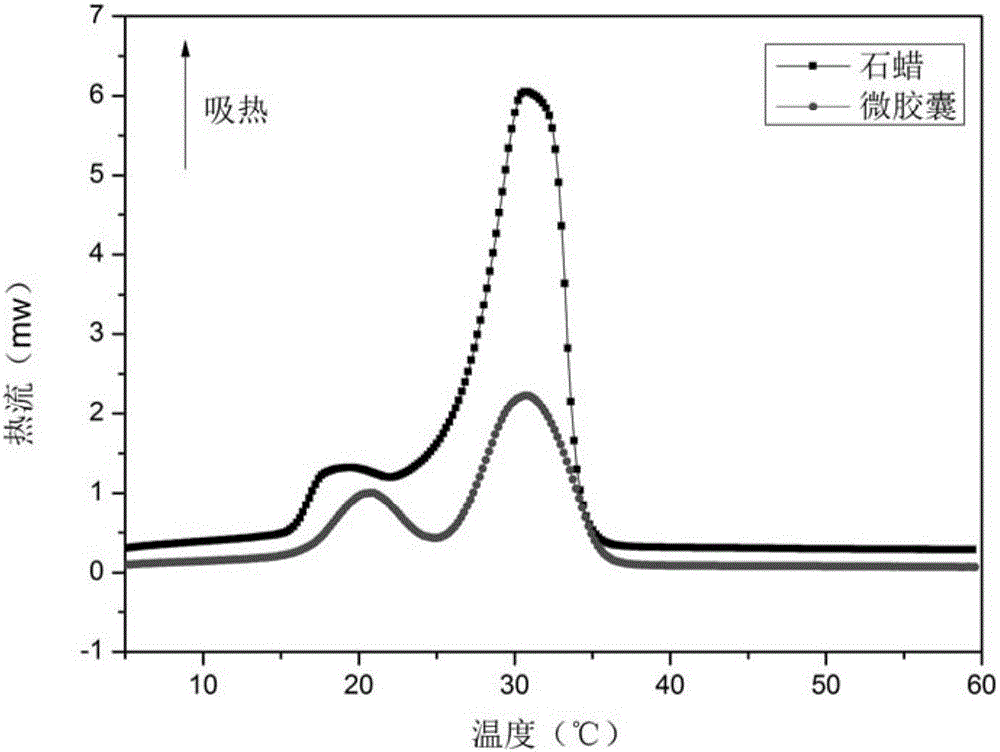

[0044] 3.0 g of titanium dioxide microsphere powder (average particle size: 300 nm) modified by vinyltriethoxysilane on the surface was ultrasonically dispersed in 20 mL of water to obtain the water phase; 4.5 g of phase-change paraffin (melting point 30°C), 1g of methyl methacrylate and 2.0g of methacrylic acid, 0.2g of azobisisoheptanonitrile and 0.01g of butanediol dimethacrylate were stirred and mixed uniformly at room temperature to obtain an oil phase; the water phase was mixed with the oil phase , using a high-speed homogenizer to stir at a high speed of 19000rpm for 3 minutes to obtain an oil-in-water emulsion; transfer the emulsion to a two-necked bottle, pass nitrogen gas to remove oxygen, then rai...

Embodiment 3

[0046] The surface modification of titanium dioxide microsphere powder refers to the method of Example 1, but adopts propenyl (chloromethyl) dimethylsilane as a modifier, and the concentration of the modifier solution is 10 vol%, and the remaining conditions are the same as in Example 1.

[0047] 2.5 g of titanium dioxide microsphere powder (average particle size: 600 nm) modified by propenyl (chloromethyl) dimethylsilane on the surface was ultrasonically dispersed in 10 mL of water to obtain an aqueous phase; 5 g of phase-change paraffin (melting point: 20 °C), 2g methyl methacrylate (MMA), 1g styrene, 0.35g benzoyl peroxide and 0.1g ethylene glycol dimethacrylate are stirred and mixed at room temperature to obtain an oil phase; Mix with the oil phase, and use a high-speed homogenizer to stir at a high speed of 10,000 rpm for 3 minutes to obtain an oil-in-water emulsion; transfer the emulsion to a two-necked bottle, pass nitrogen gas to remove oxygen, and then raise the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com