Chrome-manganese nitrogen series austenitic heat-resistance steel and preparation method thereof

An austenitic heat-resistant steel, chromium-manganese-nitrogen-based technology, applied in the field of automotive steel, can solve the problems of inability to meet the requirements of high-performance engines, high thermal expansion coefficient, and reduced high temperature strength, and achieve improved durability and creep performance. , the effect of high thermal conductivity and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The present invention also provides a method for preparing the chromium-manganese-nitrogen austenitic heat-resistant steel described in the above technical solution, comprising the following steps:

[0022] (1) Melting the alloy raw materials of each element component to obtain a feed liquid;

[0023] (2) Put the feed liquid obtained in the step (1) to rest and then pour into molding to obtain chromium-manganese-nitrogen austenitic heat-resistant steel.

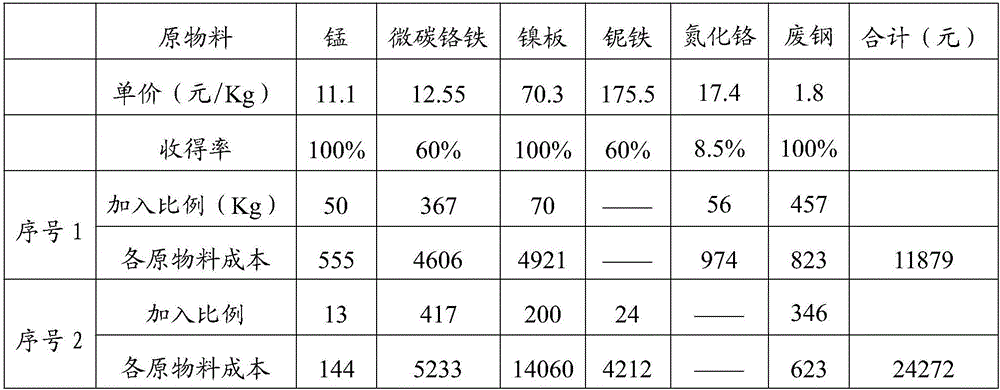

[0024] In the present invention, the sources of the alloy raw materials of each element component are not particularly limited, and commercially available alloy raw materials well known to those skilled in the art can be used; in the embodiments of the present invention, the alloy raw materials of each element component Ferro-silicon, manganese, micro-carbon ferrochrome, ferro-niobium, ferro-tungsten, ferro-vanadium, nickel plate, ferrochromium nitride alloy, metal zirconium, metal yttrium, metal cobalt, boron iron, ni...

Embodiment 1

[0036]1. Ingredients: The weight percentage distribution of main raw materials: recarburizer = 0.32%, scrap steel = 43.39%, chromium nitride = 8.58%, micro-carbon ferrochromium = 34.31%, electrolytic manganese = 5.15%, ferrosilicon = 1.25 %, nickel plate = 7.0%.

[0037] 2. Melting: The smelting equipment adopts medium-frequency induction furnace, and the capacity of the induction furnace ranges from 0.5 tons to 3 tons. Put the above-mentioned prepared raw materials into the intermediate frequency induction furnace in sequence, and then send electricity to raise the temperature; when the input materials are completely melted, continue to raise the temperature in the intermediate frequency induction furnace to 1580°C, and take the spectroscopic analysis test piece for the intermediate frequency induction furnace. The material liquid in the electric furnace is spectroscopically analyzed, and the analysis results are shown in the following table:

[0038] element

C ...

Embodiment 2

[0044] 1. Ingredients: weight percentage distribution of main raw materials: recarburizer = 0.35%, scrap steel = 43.29%, chromium nitride = 8.65%, micro-carbon ferrochrome = 33.71%, electrolytic manganese = 5.35%, ferrosilicon = 1.55 %, nickel plate = 7.1%.

[0045] 2. Melting: The smelting equipment adopts medium-frequency induction furnace, and the capacity of the induction furnace ranges from 0.5 tons to 3 tons. Put the above-mentioned prepared raw materials into the intermediate frequency induction furnace in sequence, and then send electricity to raise the temperature; when the input materials are completely melted, continue to raise the temperature in the intermediate frequency induction furnace to about 1600°C, and take the spectroscopic analysis test piece for the intermediate frequency The material liquid in the induction furnace is spectroscopically analyzed, and the analysis results are shown in the table below:

[0046] element

C

Si

mn

P

...

PUM

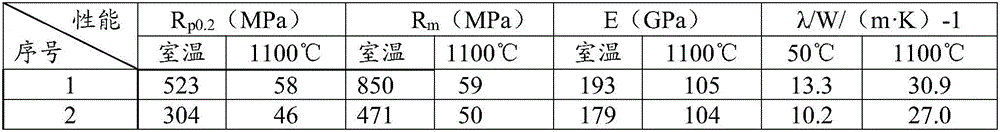

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com