Production process of high-quality phenylacetic acid

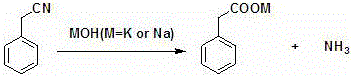

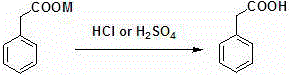

A production process, a technology of phenylacetic acid, applied in the directions of carboxylate preparation, carboxylate preparation, organic chemistry, etc., can solve the problems of the treatment process without fundamentally removing impurities, complex process, low production efficiency, etc., and achieve convenient Post-processing process, good continuity, and the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Add a 30% mass concentration sodium hydroxide aqueous solution to a 5000L enamel reaction kettle, and then add a certain amount of water to dilute the 30% mass concentration sodium hydroxide aqueous solution to 3280kg of a 15% mass concentration dilute lye. Then, start warming to reflux. Open the discharge valve of the benzyl nitrile metering tank, adjust the adding speed of 1200kg benzyl nitrile, and complete the addition in about 3 hours. During the dropwise addition, ammonia gas is released all the time, so it is necessary to ensure that the ammonia gas is discharged smoothly. After the dropwise addition was completed, the mixture was kept warm for 2 hours. The temperature was lowered to obtain an aqueous solution of sodium phenylacetate, and the pH of the aqueous solution of sodium phenylacetate was adjusted to 6.

[0047] (2) In the continuous extraction tower, pump the pH-adjusted sodium phenylacetate aqueous solution from the upper inlet, and pump the extrac...

Embodiment 2

[0052](1) Add a 30% mass concentration sodium hydroxide aqueous solution to a 5000L enamel reaction kettle, and then add a certain amount of water to dilute the 30% mass concentration sodium hydroxide aqueous solution to 3280kg of a 15% mass concentration dilute lye. Then, start warming to reflux. Open the discharge valve of benzyl nitrile metering tank, adjust the adding speed of 1200kg benzyl nitrile, finish adding in 3 hours, in the process of dropping, ammonia gas is released all the time, guarantee that ammonia gas is discharged unobstructed. After the dropwise addition is completed, keep warm for 2 hours. The temperature was lowered to obtain an aqueous solution of sodium phenylacetate. Adjust the pH of the sodium phenylacetate aqueous solution to 8.

[0053] (2) In the continuous extraction tower, the sodium phenylacetate aqueous solution after pH adjustment is pumped from the upper inlet, and the extractant isopropyl ether is pumped from the lower inlet. 35%, the ex...

Embodiment 3

[0058] (1) Add a 30% mass concentration sodium hydroxide aqueous solution to a 5000L enamel reaction kettle, and then add a certain amount of water to dilute the 30% mass concentration sodium hydroxide aqueous solution to 3280kg of a 15% mass concentration dilute lye. Then, start warming to reflux. Open the discharge valve of benzyl nitrile metering tank, adjust the adding speed of 1200kg benzyl nitrile, finish adding in 3 hours, in the process of dropping, ammonia gas is released all the time, guarantee that ammonia gas is discharged unobstructed. After the dropwise addition is completed, keep warm for 2 hours. The temperature was lowered to obtain an aqueous solution of sodium phenylacetate. Adjust the pH of the sodium phenylacetate aqueous solution to 8.

[0059] (2) In the continuous extraction tower, pump the pH adjusted sodium phenylacetate aqueous solution from the upper inlet, and pump the extractant toluene from the lower inlet. The amount of toluene is 40% of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chromatographic purity | aaaaa | aaaaa |

| chromatographic purity | aaaaa | aaaaa |

| chromatographic purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com