Lithium iron phosphate/graphene composite material as well as preparation method and application thereof

A technology of lithium iron phosphate and composite materials, applied in the direction of phosphorus compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems affecting the application, graphene is difficult to disperse, etc., to improve production efficiency, simple preparation method, liquid absorption strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The invention provides a kind of lithium iron phosphate / graphene composite material, and its preparation method comprises the following steps:

[0050] Step 1: Add 250kg of deionized water into a 500L stirred reactor;

[0051] Step 2: Add 25kg of absolute ethanol to configure the reaction kettle with a concentration of 9.1% ethanol solution;

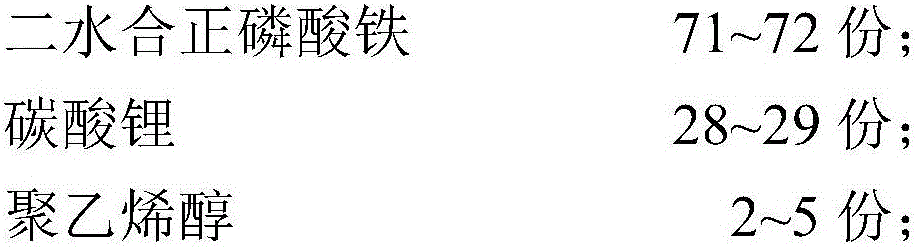

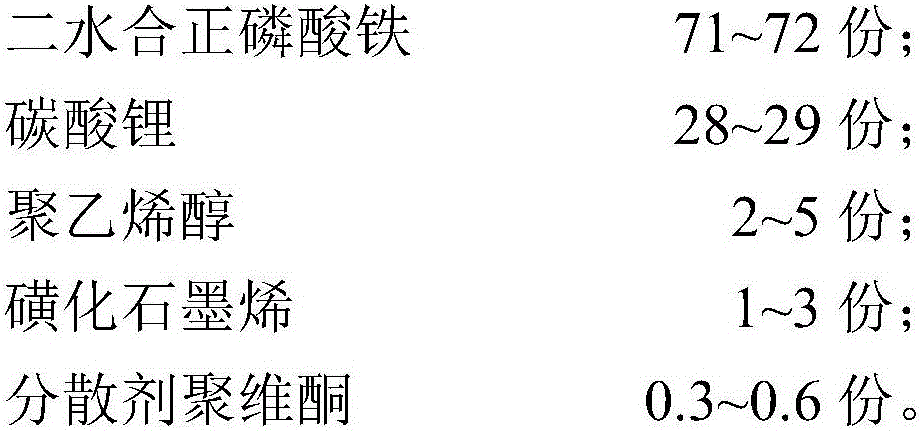

[0052] Step 3: Weigh raw materials: 71kg of ferric orthophosphate dihydrate, 29kg of battery-grade lithium carbonate, 5kg of polyvinyl alcohol, 2kg of sulfonated graphene with a sheet diameter of 13 μm to 15 μm, and the dispersant type is PVP K30 povidone (PVP) 0.3 kg;

[0053] Step 4: Add the raw materials weighed in step 3 into the reactor, and stir in the reactor to obtain a slurry with a solid content of 28.1%;

[0054] Step 5: Grinding the stirred slurry for 4 hours at a linear speed of 12m / s through a sand mill adding 0.3mm zirconium balls;

[0055] Step 6: Dry the ground slurry by spray drying. The inlet temperature of s...

Embodiment 2

[0058] The invention provides a kind of lithium iron phosphate / graphene composite material, and its preparation method comprises the following steps:

[0059] Step 1: Add 300kg of deionized water into a 500L stirred reactor;

[0060] Step 2: Add 20kg of absolute ethanol to configure the reaction kettle with a concentration of 6.3% ethanol solution;

[0061] Step 3: Weigh raw materials: 100kg of ferric orthophosphate dihydrate, 40kg of industrial grade lithium carbonate, 4kg of polyvinyl alcohol, 2kg of sulfonated graphene with a sheet diameter of 8 μm to 9 μm, and the type of dispersant is PVP K15 povidone (PVP) 0.5 kg;

[0062] Step 4: Add the raw materials weighed in step 3 into the reactor, and stir in the reactor to obtain a slurry with a solid content of 31.4%;

[0063]Step 5: Grinding the stirred slurry for 3 hours at a linear speed of 14m / s through a sand mill adding 0.35mm zirconium balls;

[0064] Step 6: Dry the ground slurry by spray drying. The inlet temperature...

Embodiment 3

[0067] The invention provides a kind of lithium iron phosphate / graphene composite material, and its preparation method comprises the following steps:

[0068] Step 1: Add 380kg of deionized water into a 500L stirred reactor;

[0069] Step 2: Add 30kg of absolute ethanol to configure the reaction kettle with a concentration of 7.3% ethanol solution;

[0070] Step 3: Weigh raw materials: 150kg of ferric orthophosphate dihydrate, 59.8kg of battery-grade lithium carbonate, 9.4kg of polyvinyl alcohol, 5.9kg of sulfonated graphene with a sheet diameter of 25 μm to 28 μm, and the dispersant model is PVP K90 povidone ( PVP) 1kg;

[0071] Step 4: Add the raw materials weighed in step 3 into the reactor, and obtain the slurry by stirring in the reactor;

[0072] Step 5: Grinding the stirred slurry for 2 hours at a linear speed of 14m / s through a sand mill adding 0.4mm zirconium balls;

[0073] Step 6: Dry the ground slurry by spray drying. The inlet temperature of spray drying is 298...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com