Low-temperature thermal plasma method for preparing catalyst for preparing low-carbon alcohol from synthesis gas and application

A plasma and catalyst technology, applied in the field of catalyst preparation by ionic method, can solve the problems of poor mechanical stability, low catalytic activity, low selectivity, etc., and achieve the effects of good dispersibility, high selectivity and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

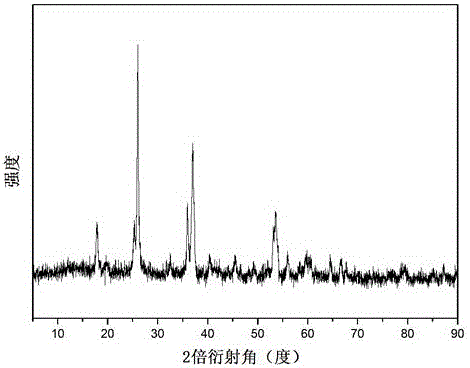

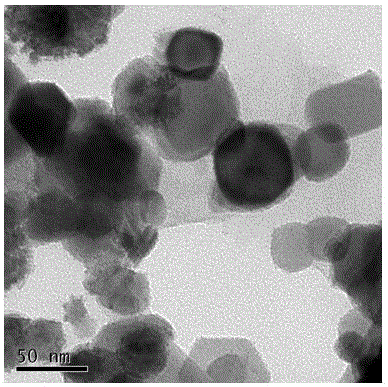

Image

Examples

Embodiment 1

[0019] Weigh 61.79g of ammonium molybdate and 14.51g of dicobalt trioxide (Co / Mo is 1:2), mix them uniformly by mechanical means, dry in an oven at 120°C for 24 hours, and after cooling to room temperature, grind them in a mortar for 80 After the mesh screen, it is added to the plasma instrument feed bin.

[0020] The parameters of the plasma equipment are adjusted as follows: the gas used is high-purity argon, and the middle gas is 0.5 m 3 / h, edge gas 4.5 m 3 / h, carrier gas 0.2 m 3 / h, the feed rate is 7.27 g / min, and the instrument power is 10kW.

[0021] The product is impregnated with potassium carbonate solution (n K / (n Mo + n Co ) = 5%), dried at 120°C for 24 hours after impregnation, pressed into tablets after cooling, and sieved to collect 40-60 mesh catalysts.

[0022] The K-Co-MoO prepared by the above method 2 Catalysts were evaluated for catalytic performance in a stainless steel fixed-bed reactor. The inner diameter of the reactor is 8mm, and the loadin...

Embodiment 2

[0025] Change the mass of dicobalt trioxide to 29.03g, and the mass of ammonium molybdate is still 61.79g (Co / Mo is 1:1), and other conditions are the same as in Example 1. The results of the catalytic evaluation showed that the CO conversion rate was 46.8%, the total alcohol selectivity was 51.6%, and the C 2+ The alcohol selectivity is 71.7%, and the space-time yield is 178.7mg / mL / h.

Embodiment 3

[0027] Change the mass of dicobalt trioxide to 58.06g, and the mass of ammonium molybdate is still 61.79g (Co / Mo is 2:1), and other conditions are the same as in Example 1. The results of the catalytic evaluation showed that the CO conversion rate was 51.5%, the total alcohol selectivity was 50.4%, and the C 2+ The alcohol selectivity is 70.5%, and the space-time yield is 222.1 mg / mL / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com