Preparation method of nano-metal oxide

A nano metal and oxide technology, applied in rare earth metal oxides/hydroxides, rare earth metal compounds, chemical instruments and methods, etc., can solve certain problems in the stability of nano metal oxides and the slow reaction speed of ammonium nitrate mixtures , Ammonium nitrate cannot achieve self-sustained combustion and other problems, to reduce energy consumption, improve stability and particle size controllability, and facilitate industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

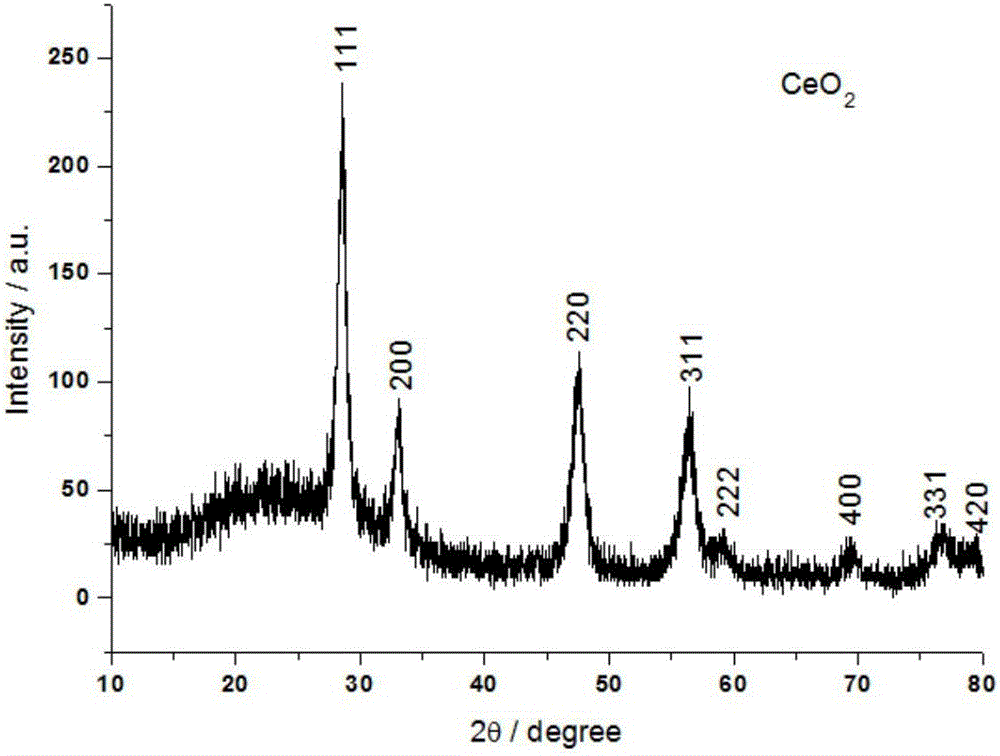

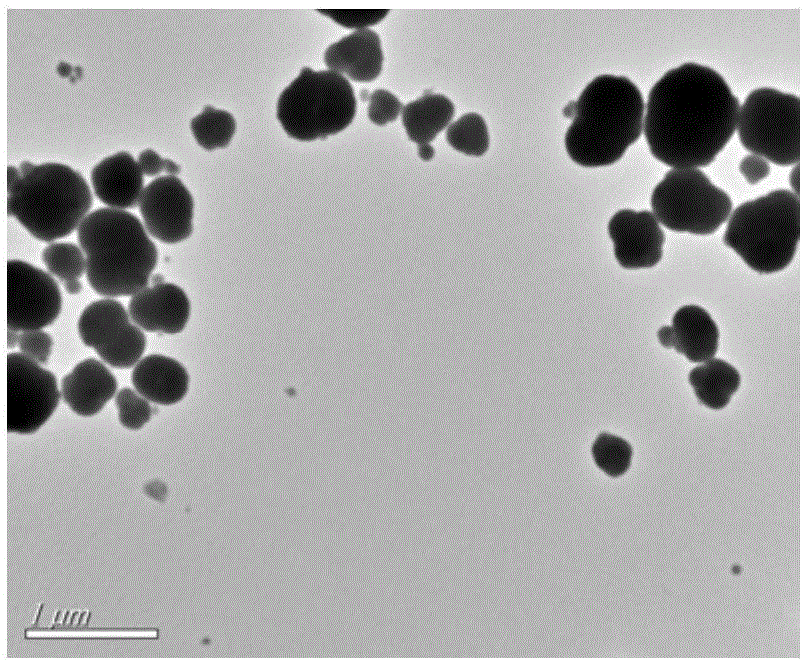

[0029] Prepare nano cerium oxide according to the inventive method, this experiment is divided into three steps, and the first step is to prepare nitrate mixture, and component mass fraction is, ammonium nitrate: cerium nitrate: water: octadecylamine acetate=60:30: 9.85:0.15, Dissolve ammonium nitrate and cerium nitrate in water, add emulsifier octadecylamine acetate, heat at 110-120°C to dissolve evenly, pour it into a vacuum tank, and vacuum it under the pressure of -0.085MPa to obtain a uniform The expanded porous nitrate mixture; the second step is to prepare the nitrate and oil phase mixture, and the nitrate mixture and diesel oil are uniformly mixed according to the mass ratio of 94:6; the third step is to calcinate the mixture, and place the mixture in the horse Calcined in a Furnace, the calcination temperature was set at 600°C, and the calcination time was 1h. The calcined product is taken out from the muffle furnace, washed and purified to obtain the finished product...

Embodiment 2

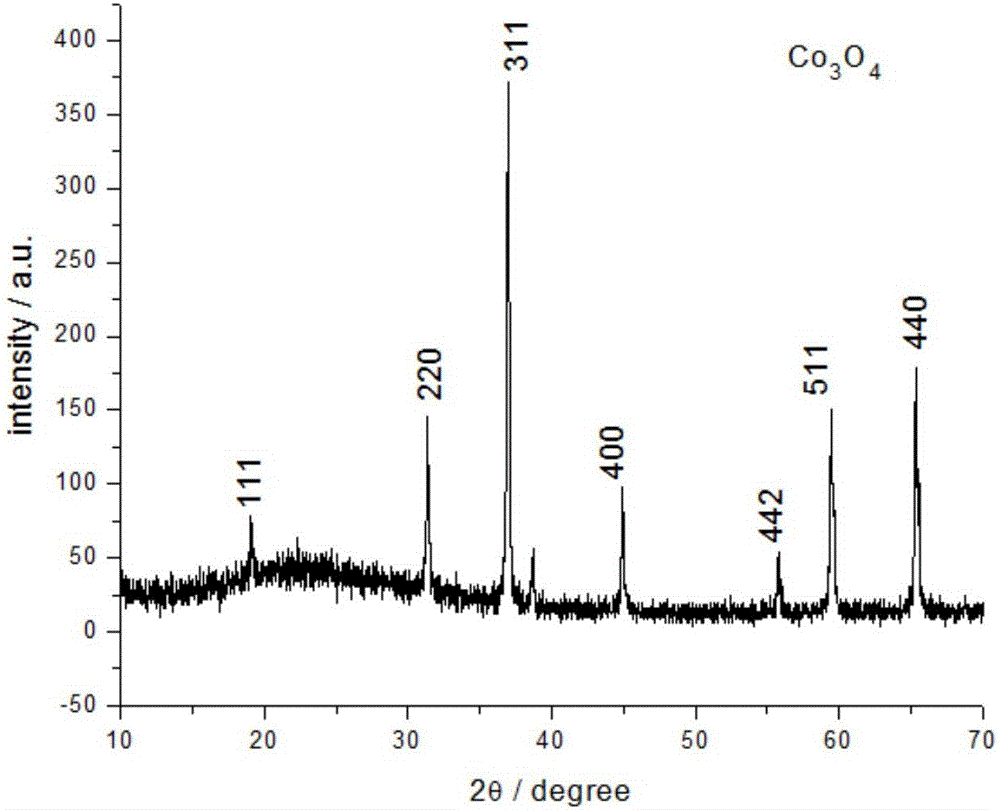

[0031] Prepare nano-cobalt tetroxide according to the inventive method, this experiment is divided into three steps, the first step is to prepare nitrate mixture, and component mass fraction is, ammonium nitrate: cobalt nitrate: water: octadecylamine acetate=60:35:4.8 : 0.2, Dissolve ammonium nitrate and cobalt nitrate in water, add emulsifier octadecylamine acetate, heat 110-120 ℃ to dissolve evenly, pour into vacuum tank, vacuumize under the pressure of -0.08MPa to obtain uniform Expanded porous nitrate mixture; the second step is to prepare the nitrate and oil phase mixture, uniformly mix the nitrate mixture and diesel oil according to the mass ratio of 94:6; the third step is to calcine the mixture, and place the mixture in the muffle furnace Medium calcination, the calcination temperature is set at 700°C, and the calcination time is 1.5h. The calcined product is taken out from the muffle furnace, washed and purified to obtain the finished product of nano-cobalt trioxide. ...

Embodiment 3

[0033] Prepare nano copper oxide according to the inventive method, this experiment is divided into three steps, and the first step is to prepare nitrate mixture, and component mass fraction is, ammonium nitrate: copper nitrate: water: octadecylamine=30.85:60:9:0.15 , Dissolve ammonium nitrate and copper nitrate in water, add emulsifier octadecylamine and heat it at 110-120°C to dissolve evenly, then pour it into a vacuum tank, and vacuum it under the pressure of -0.09MPa to obtain uniform expanded porous nitrate The mixture; the second step is to prepare the mixture of nitrate and oil phase, and the nitrate mixture and the oil phase are uniformly mixed according to the mass ratio of 93:7; the third step is to calcinate the mixture, and the oil phase is nitric acid with a mass ratio of 1:1. Nasi 801 and paraffin mixture, the mixture is placed in a muffle furnace for calcination, the calcination temperature is set at 1000°C, and the calcination time is 1.5h. The calcined produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com