Novel water-soluble reaction type ultraviolet absorbent and preparation method thereof

A UV absorber, water-soluble technology, applied in chemical instruments and methods, other chemical processes, sugar derivatives, etc., can solve the problems of no active group, poor reactivity, etc., to achieve simple method, good water solubility, high yield high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

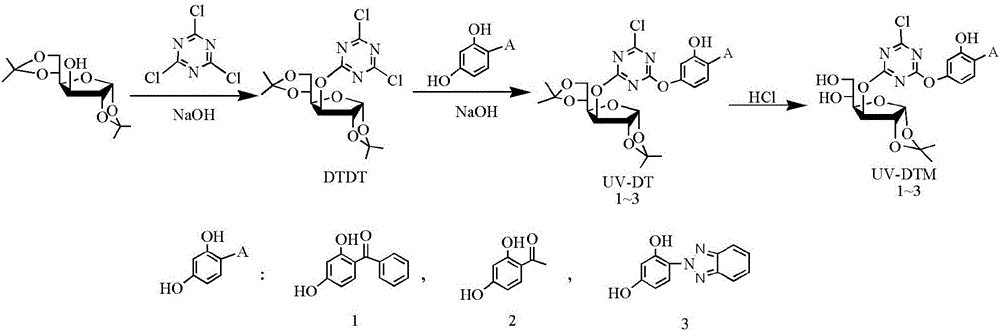

[0037] Example 1: 3-(4,6-dichloro-1,3,5-triazine-2-oxyl)-1,2,5,6-diisopropylidene-α-D-glucose (DTDT) Synthesis

[0038]Dissolve 1.46g (8mmol) of cyanuric chloride (TCT) in 20mL of acetone, stir and swell at 0°C for 10min, then slowly add diacetone-glucose and NaOH to the solution dropwise in an acetone-water mixed solution. The mixed solution is composed of 2.60 g (10 mmol) of diacetone glucose dissolved in 20 mL of acetone, and the water (10 mL) solution in which 0.68 g (17 mmol) of NaOH is dissolved is added dropwise with stirring at zero temperature. The reaction was followed by TLC. After the reaction was completed, the solvent was removed by rotary evaporation to obtain a light yellow oily product, which was purified by column chromatography (eluent: ethyl acetate:petroleum ether=1:6) to obtain a white solid 3-(4,6-dichloro-1,3 ,5-triazine-2-oxy)-1,2,5,6-diisopropylidene-α-D-glucose (DTDT). Yield: 73%.

[0039] Using the method of parallel experiment, the effects of t...

Embodiment 2

[0047] Example 2: 3-(2-(2-Hydroxyphenylbenzophenone-4-oxyl)-4-chloro-1,3,5-triazine-6-oxyl)-1,2,5, Synthesis of 6-diisopropylidene-α-D-glucose (UV-DT)

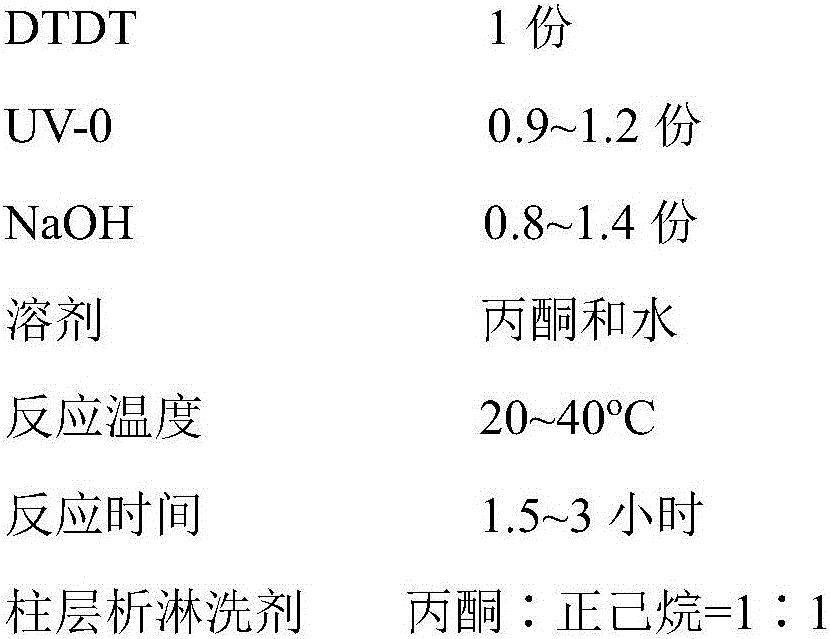

[0048] Dissolve 2.04g (5mmol) DTDT in 30mL of acetone, mix acetone (20mL) with 0.96g (4.5mmol) of UV-0 dissolved in it and an aqueous solution (10mL) with 0.20g (5mmol) of NaOH, and slowly add it dropwise into the DTDT solution. The whole system was reacted at 30°C for 2h. The solvent was removed by rotary evaporation, and the remaining yellow solid was washed repeatedly with ethanol, and purified by column chromatography (eluent: acetone:n-hexane=1:1) to obtain a white powder 3-(2-(2-hydroxyphenylbenzophenone-4 -oxy)-4-chloro-1,3,5-triazine-6-oxy)-1,2,5,6-diisopropylidene-α-D-glucose (UV-DT). Yield: 74%.

[0049] The substitution of the second chlorine of cyanuric chloride is often reacted at room temperature, and the reaction with the hydroxyl group needs to add alkali as a catalyst. Therefore, the ratio of the reaction ...

Embodiment 3

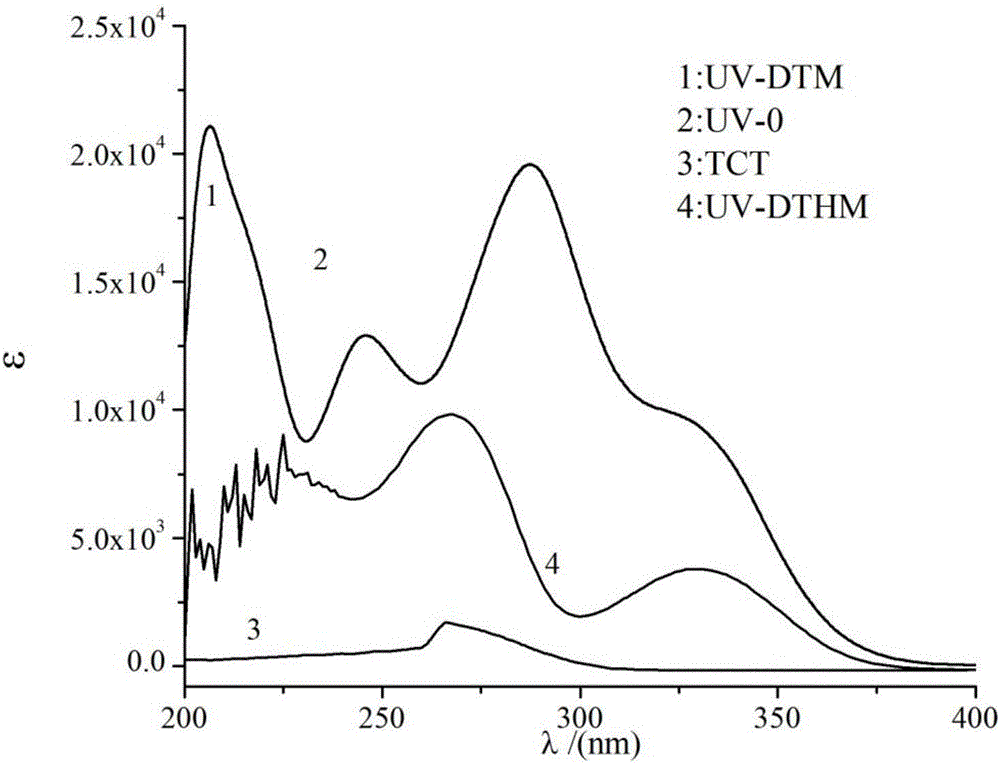

[0054] Example 3: 3-(2-(2-hydroxyphenylbenzophenone-4-oxyl)-4-chloro-1,3,5-triazine-6-oxyl)-1,2-isopropyl Synthesis and properties of fork-α-D-glucose (UV-DTM)

[0055] Dissolve 0.59g (1mmol) of UV-DT in 10mL of tetrahydrofuran, add 0.50mL of hydrochloric acid (36%) solution, stir at room temperature for 5 hours, and remove the solvent by rotary evaporation. The crude product is subjected to column chromatography (eluent is ethyl acetate : Petroleum ether = 1: 1) to obtain the hydrolyzed product 3-(2-(2-hydroxyphenylbenzophenone-4-oxyl group)-4-chloro-1,3,5-triazine-6-oxyl group )-1,2-Isopropylidene-α-D-glucose (UV-DTM). Yield: 74%.

[0056] The protection group of propylidene ketone will be deprotected under acidic conditions, but other ether bonds in the structure will also be broken when heated under acidic conditions. Trifluoroacetic acid) catalyzes the impact on the hydrolysis reaction, wherein almost no product is generated when acetic acid is used, and the point of U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com