Preparing method of composite electrode material and application thereof

A composite electrode and electrode sheet technology, which is applied in the directions of hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, battery electrodes, etc., can solve the problems of troublesome use, high commercialization cost, poor conductivity, etc. Good, reduce the effect of commercialization cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

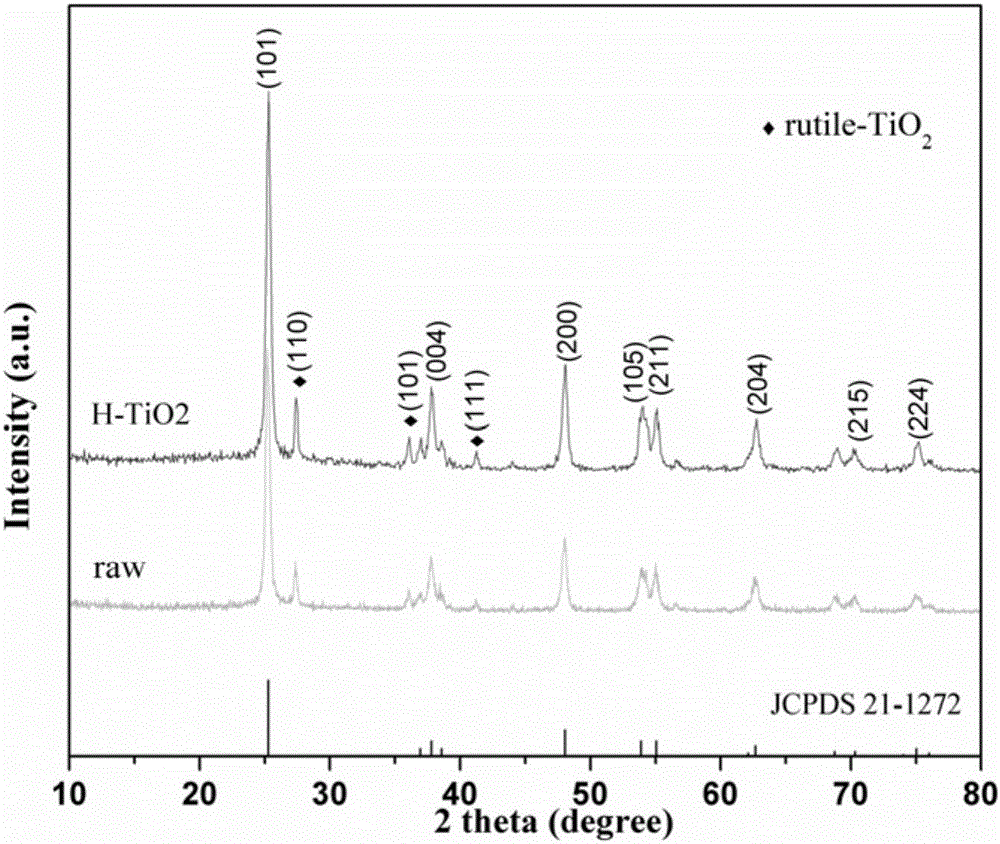

[0036] 1. Hydrogenation treatment: P25 type TiO 2 The powder sample was heat-treated in a vacuum reactor at 300°C in an argon atmosphere for 30 minutes to remove impurities on the surface and lowered to room temperature; 2 In the atmosphere, the temperature was raised to 300-650°C (interval 50°C) at 5°C / min and then kept for 3 hours to obtain H-TiO with different contents of oxygen vacancy defects 2 ;

[0037] 2. Electrode sheet preparation: H-TiO under different temperature treatments 2 : Acetylene black: PVDF=8:1:1 Grinding fully and uniformly coated on the surface of copper foil and drying at 120°C; then cut into 16*16mm electrode sheets and assembled with lithium sheets in an argon-filled glove box to form a half-cell , to test and compare the electrochemical performance at different treatment temperatures.

[0038] Different treatment temperature ℃ Specific capacity (0.1C after 20 cycles) mAh / g raw material 76 300 82 400 125 450 127 ...

Embodiment 2

[0041] 1. Hydrogenation treatment: P25 type TiO 2 The powder sample was heat-treated in a vacuum reactor at 300 °C in an argon atmosphere for 30 min to remove impurities on the surface, and then cooled to room temperature; then in Ar / H 2 In the atmosphere, the temperature was raised to 550°C at 5°C / min and then kept for 3 hours to obtain H-TiO with oxygen vacancy defects 2 ;

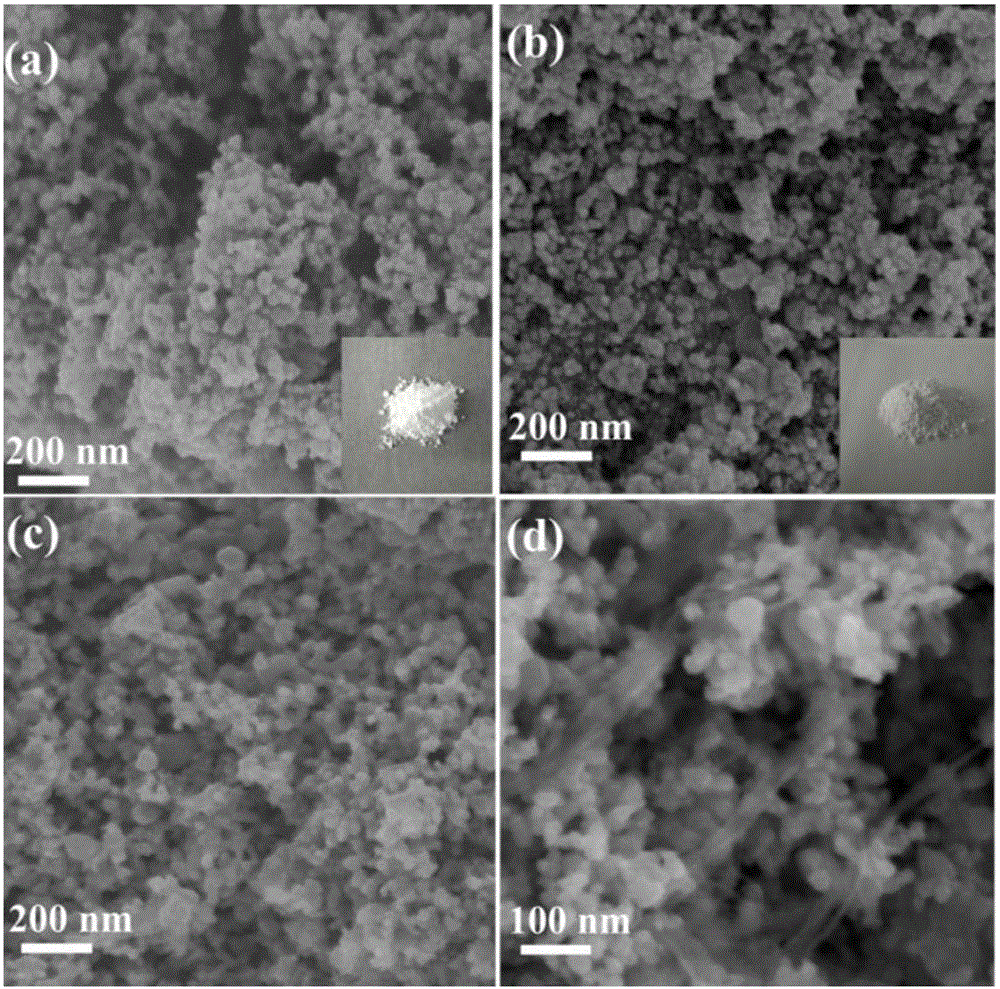

[0042] 2. Coating: add 84μl pyrrole monomer and 92μl phytic acid into 2.50ml isopropanol and ultrasonically disperse to obtain the first solution; mix the aqueous solution containing 0.274g ammonium persulfate with 60mgH-TiO 2 and TiO 2 Add it to the first solution, carry out ultrasonic dispersion and polymerization for 5 minutes, and obtain H-TiO coated with polypyrrole gel. 2 and TiO 2 granular gel;

[0043] 3. Electrode sheet preparation: the obtained H-TiO coated with polypyrrole gel 2 and TiO 2 The gel of the particles is directly and evenly coated on the surface of copper foil. After drying ...

Embodiment 3

[0045] 1. Hydrogenation treatment: P25 type TiO 2 The powder sample was placed in a vacuum reactor at 300 °C in an argon atmosphere for 30 min to remove impurities on the surface, and the treated material was placed in Ar / H 2 In the atmosphere, the temperature was raised to 550°C at 5°C / min and then kept for 3 hours to obtain H-TiO with oxygen vacancy defects 2 ;

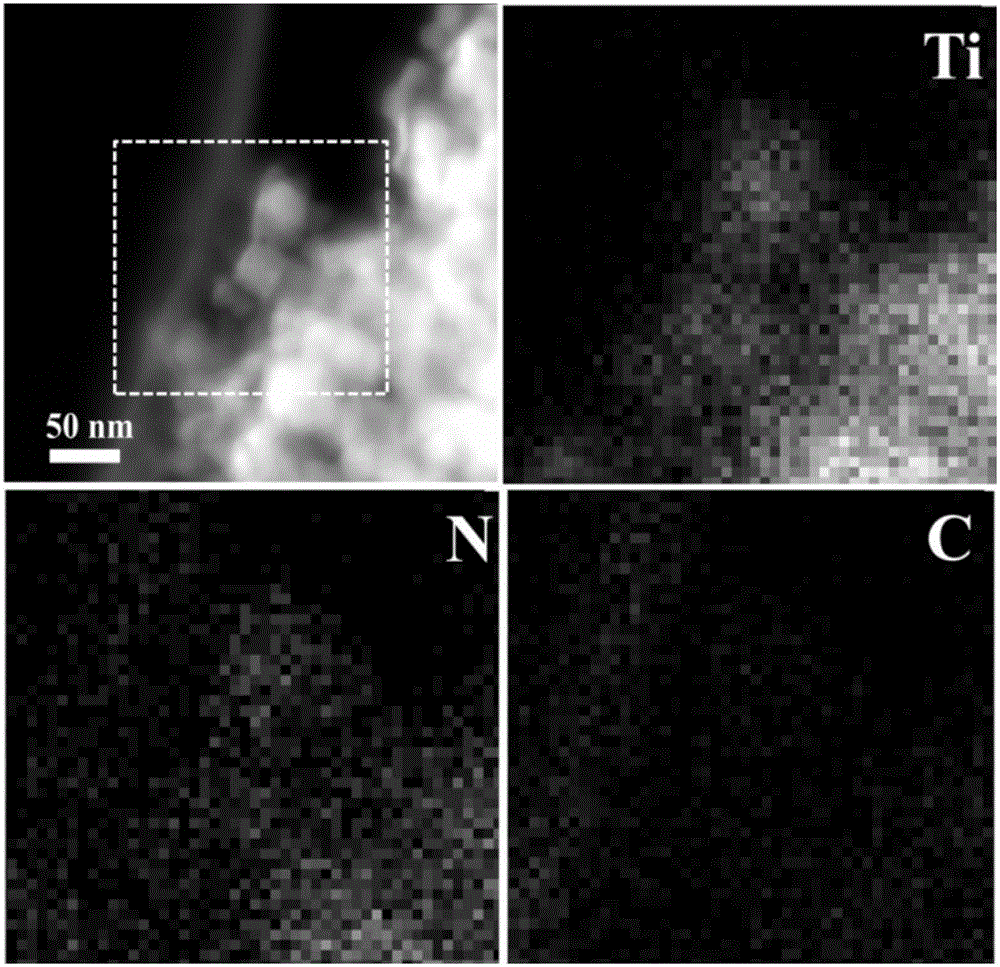

[0046] 2. Coating: Add 84 μl of pyrrole monomer and 184 μl of phytic acid solution (50% to water mass ratio) into 2.50 ml of isopropanol and ultrasonically disperse to obtain the first solution; mix 0.274 g of ammonium persulfate with 60 mg of H-TiO 2 Add it into the first solution, conduct ultrasonic dispersion, and polymerize for 20 minutes to obtain H-TiO coated with polypyrrole gel 2 a second solution of particles;

[0047] 3. Cross-linking: add 0.8 mg of single-walled carbon nanotubes to the second solution, carry out ultrasonic dispersion, and cross-linking reaction for 5 minutes to obtain TiO 2 / polypyrro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com