Chemical polishing method for gallium arsenide substrate

A chemical polishing, gallium arsenide technology, applied in the field of material processing, can solve the problems of poor control of corrosion rate, increase product cost, increase optoelectronic performance, etc., to improve the phenomenon of electrode loss, improve product yield, and improve optoelectronic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of chemical polishing method of gallium arsenide substrate, comprises steps as follows:

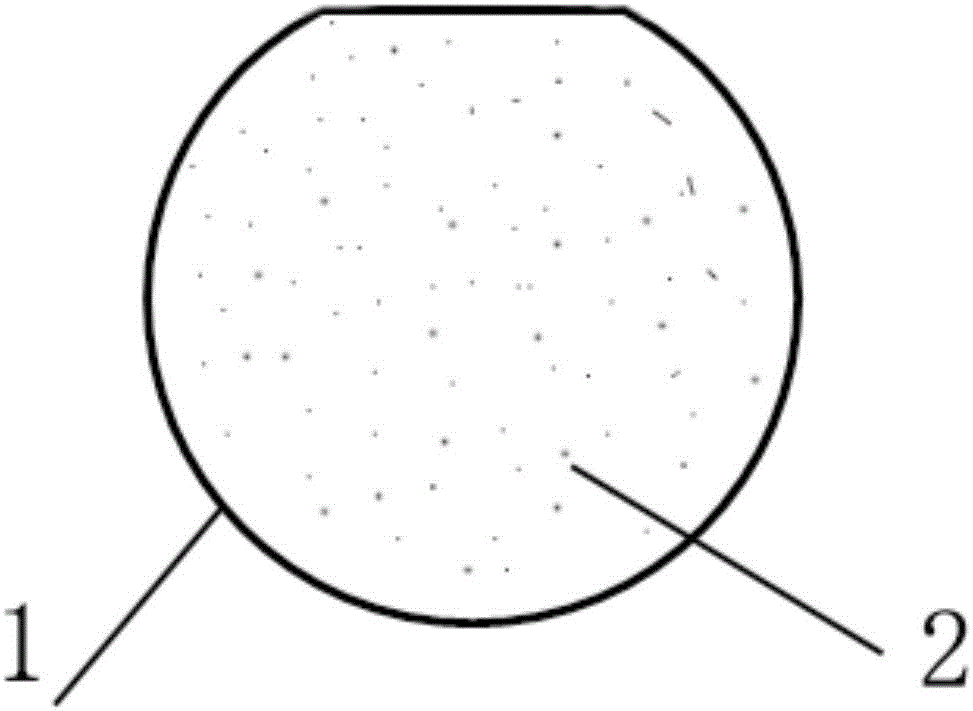

[0037] (1) Scrub the gallium arsenide substrate after the thinning process and dry it with nitrogen gas with a purity of 99.9%, and measure the thickness h of the substrate 1 It is 232.5μm, and there is no black particles and other impurities on the surface when observed under a microscope;

[0038] Use sodium hydroxide solid with a purity of 96% to configure an aqueous sodium hydroxide solution with a mass concentration of 35%. During the configuration process, the sodium hydroxide solid is first added to the beaker, and then slowly added with a conductivity of 0.17μs / cm (25°C). Deionized water and stirring continuously, after the sodium hydroxide solid is completely dissolved, let it stand for 38 minutes for later use, and store at an ambient temperature of 26°C;

[0039] Slowly add hydrogen peroxide with a purity of 30% to the prepared aqueous sodium hydroxide solution, ...

Embodiment 2

[0046] A kind of chemical polishing method of gallium arsenide substrate, comprises steps as follows:

[0047] (1) Scrub the gallium arsenide substrate after the thinning process and dry it with nitrogen gas with a purity of 99.9%, and measure the thickness h of the substrate 1 It is 209.8μm, and there are no impurities such as black particles on the surface observed under a microscope;

[0048] Use potassium hydroxide solid with a purity of 98% to configure a potassium hydroxide aqueous solution with a mass concentration of 50%. During the configuration, the potassium hydroxide solid is first added to the beaker, and then slowly added with a conductivity of 0.15μs / cm (25°C). Deionized water and stirring continuously, after the potassium hydroxide solid is completely dissolved, let it stand for 45 minutes for later use, and store at an ambient temperature of 25°C;

[0049] Slowly add hydrogen peroxide with a purity of 32% to the prepared potassium hydroxide aqueous solution, ...

Embodiment 3

[0056] A kind of chemical polishing method of gallium arsenide substrate, comprises steps as follows:

[0057] (1) Scrub the gallium arsenide substrate after the thinning process and dry it with nitrogen gas with a purity of 99.9%, and measure the thickness h of the substrate 1 It is 171.5μm, and there is no black particles and other impurities on the surface when observed under a microscope;

[0058] Use sodium hydroxide solid with a purity of 97% to configure an aqueous sodium hydroxide solution with a mass concentration of 65%. During the configuration, the sodium hydroxide solid is first added to the beaker, and then slowly added with a conductivity of 0.12μs / cm (25°C). Deionized water and stirring continuously, after the sodium hydroxide solid is completely dissolved, let it stand for 54 minutes for use, and store at an ambient temperature of 23°C;

[0059] Slowly add hydrogen peroxide with a purity of 30% to the prepared aqueous sodium hydroxide solution, and stir conti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com