Composite lithium iron phosphate/carbon coated core-shell type lithium ferric manganese phosphate anode material and preparation method thereof

A composite positive electrode material, lithium manganese iron phosphate technology, applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems of poor capacity retention, low electronic conductivity, low discharge capacity, etc., to improve conductivity, preparation method Simple, reduces the effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

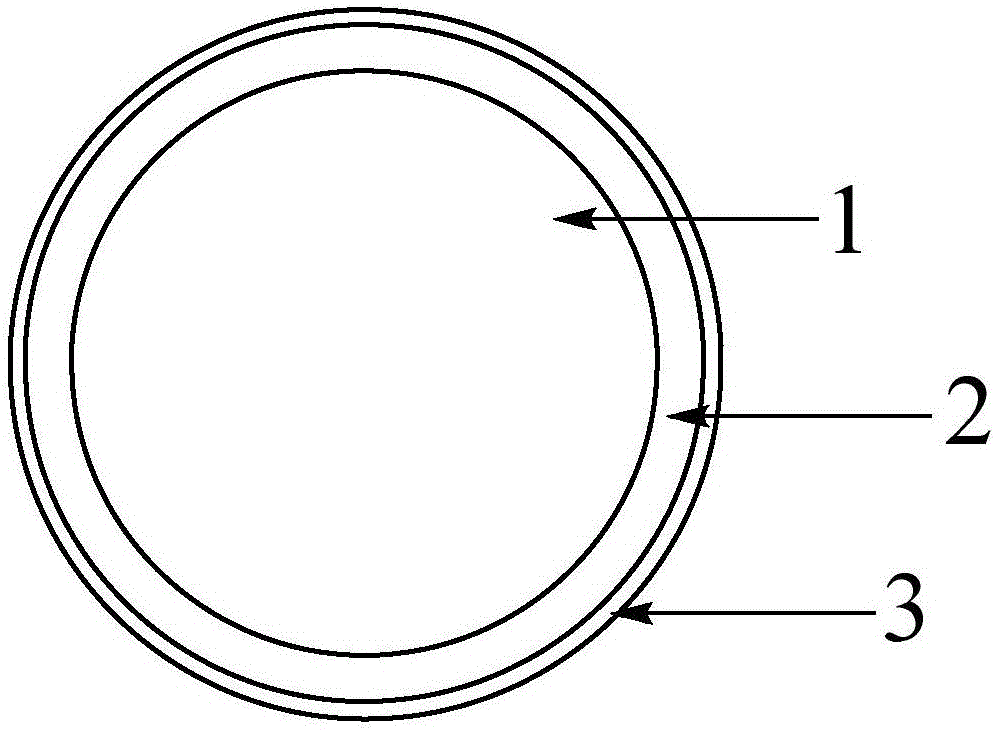

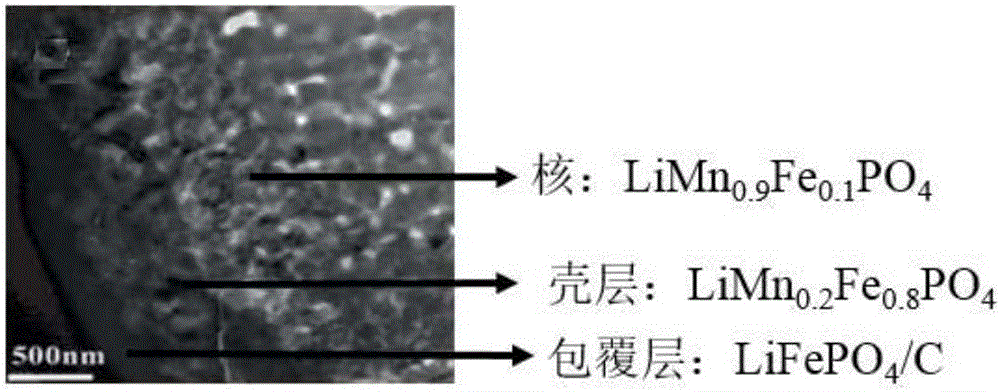

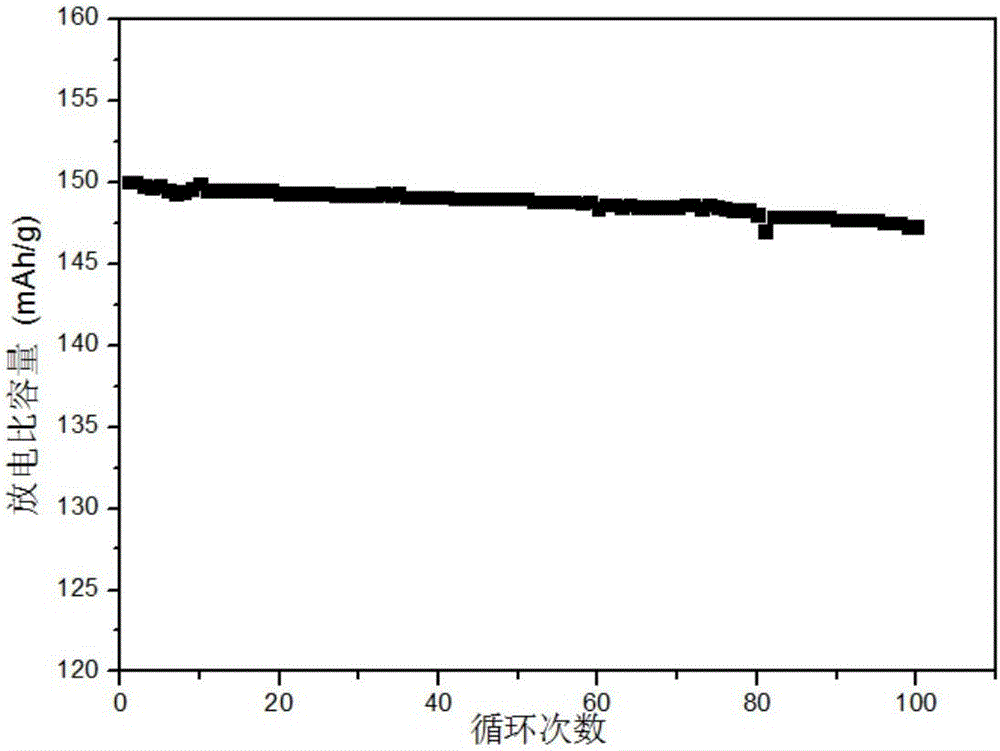

[0029] Lithium iron phosphate / carbon-coated core-shell type lithium manganese iron phosphate composite positive electrode material, its composition formula is: LiMn 0.9 Fe 0.1 PO 4 / LiMn 0.2 Fe 0.8 PO 4 / LiFePO 4 / C, where the core material accounts for 80% by weight, the shell material accounts for 15% by weight, the lithium iron phosphate accounts for 3% by weight in the cladding material, and the carbon accounted for by weight in the cladding material The percentage is 2%.

[0030] 1. Preparation of crystalline Mn 0.9 Fe 0.1 PO 4 Anhydrous compound: Mix 9 mol of manganese nitrate and 1 mol of ferrous oxalate in ethanol, add 1 mol of H while stirring 3 PO 4 Solution, after reacting at 30°C for 4 hours, a gray-green precipitate was obtained, and the product was filtered and washed to obtain amorphous Mn 0.9 Fe 0.1 PO 4 Hydrate, vacuum dried at 80°C for 24h, and then calcined at 800°C for 10h under nitrogen atmosphere to obtain crystalline Mn 0.9 Fe 0.1 PO 4 an...

Embodiment 2

[0040] Lithium iron phosphate / carbon-coated core-shell type lithium manganese iron phosphate composite positive electrode material, its composition formula is: LiMn 0.85 Fe 0.15 PO 4 / LiMn 0.3 Fe 0.7 PO 4 / LiFePO 4 / C, wherein the nuclear material accounts for 70% by weight, the shell material accounts for 20% by weight, the lithium iron phosphate accounts for 7% by weight in the clad material, and the carbon accounted for by weight in the clad material The percentage is 3%.

[0041] 1. Preparation of crystalline Mn 0.85 Fe 0.15 PO 4 Anhydrous compound: mix 8.5mol of manganese sulfate and 1.5mol of ferric nitrate in ethanol, add 1mol of H while stirring 3 PO 4 Solution, after reacting at 30°C for 7 hours, a gray-green precipitate was obtained, and the product was filtered and washed to obtain amorphous Mn 0.85 Fe 0.15 PO 4 Hydrate, vacuum dried at 80°C for 24h, and then calcined at 700°C for 20h under argon atmosphere to obtain crystalline Mn 0.85 Fe 0.15 PO 4 ...

Embodiment 3

[0046] Lithium iron phosphate / carbon-coated core-shell type lithium manganese iron phosphate composite positive electrode material, its composition formula is: LiMn 0.8 Fe 0.2 PO 4 / LiMn 0.4 Fe 0.6 PO 4 / LiFePO 4 / C, wherein the nuclear material accounts for 60% by weight, the shell material accounts for 30% by weight, the lithium iron phosphate accounts for 7% by weight in the clad material, and the carbon accounted for by weight in the clad material The percentage is 3%.

[0047] 1. Preparation of crystalline Mn 0.8 Fe 0.2 PO 4 Anhydrous compound: mix 8.0mol manganese sulfate and 2.0mol ferric nitrate in ethanol, add 1mol H while stirring 3 PO 4 Solution, after reacting at 30°C for 6 hours, a gray-green precipitate was obtained, and the product was filtered and washed to obtain amorphous Mn 0.8 Fe 0.2 PO 4 Hydrate, vacuum dried at 80°C for 24h, and then calcined at 650°C for 15h in an argon-hydrogen (95:5) atmosphere to obtain crystalline Mn 0.8 Fe 0.2 PO 4 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com