Adamantine mono-quaternary ammonium salt cationic three compound combination flooding produced water oil remover

A quaternary ammonium salt cation and ternary composite technology, which is applied in the field of adamantane single quaternary ammonium cation type three-component compound flooding degreasing agent, can solve the problems of high cost and difficult regeneration, and achieve excellent temperature resistance, Effect of high oil removal efficiency and strong interface modification function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

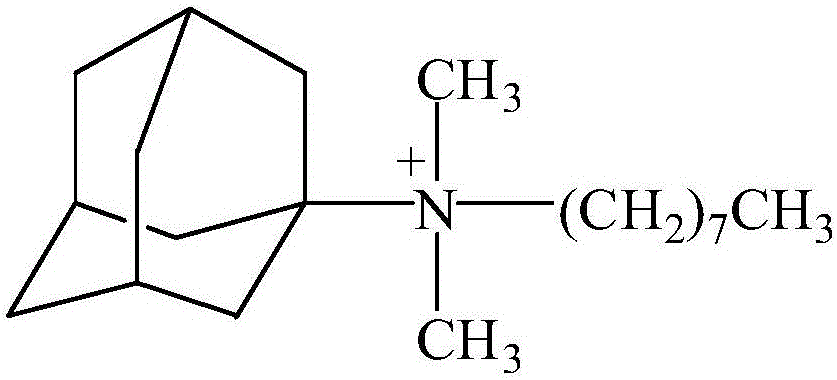

Image

Examples

Embodiment 1

[0029] Embodiment 1: Degreaser BD 1 and its preparation method

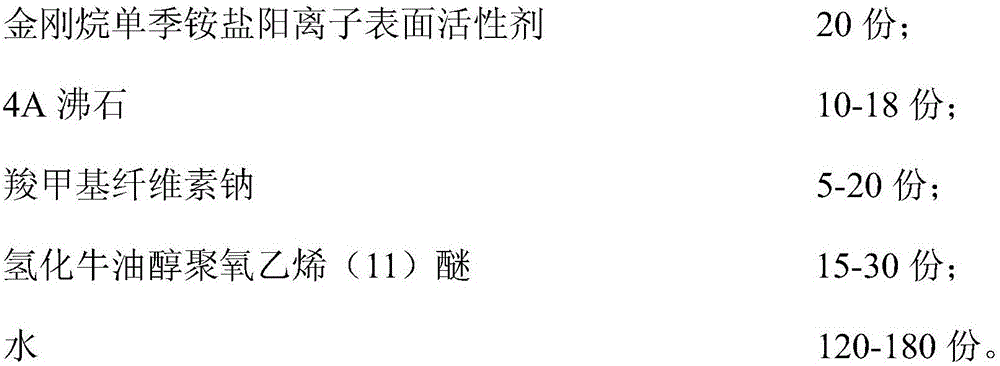

[0030] (1) Degreaser BD 1 The composition and its components are as follows:

[0031]

[0032] According to existing literature, the preparation method of described adamantane monoquaternary ammonium salt cationic surfactant is as follows:

[0033]

[0034] (2) Degreaser BD 1 The preparation method is as follows:

[0035] ① Mix 20 parts of adamantane monoquaternary ammonium cationic surfactant and 5 parts of sodium carboxymethylcellulose into the first beaker, add 40 parts of water, heat while stirring, the stirring rate is 250ppm, and the heating temperature 40°C, the heating time is 20min, after the heating time is over, the temperature is naturally cooled to room temperature to obtain the mixed solution A;

[0036] ② Mix 10 parts of 4A zeolite and 15 parts of hydrogenated tallow alcohol polyoxyethylene (11) ether into the second beaker, add 40 parts of water, and heat while stirring. The stirring ra...

Embodiment 2

[0038] Embodiment 2: Degreaser BD 2 and its preparation method

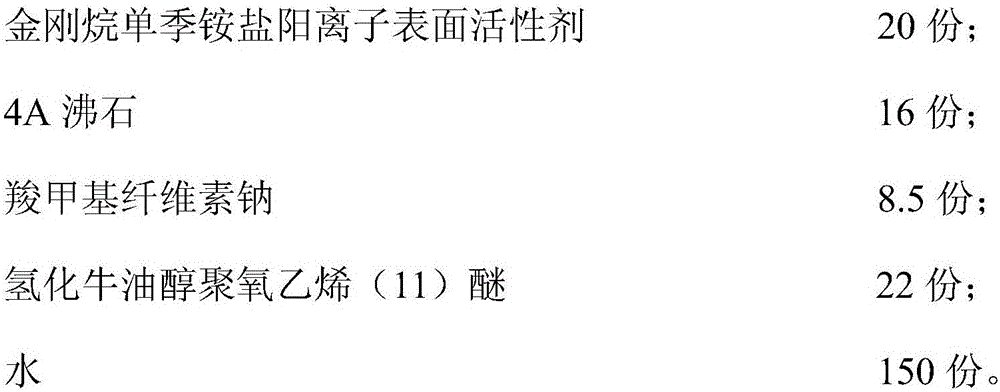

[0039] (1) Degreaser BD 2 The composition and its components are as follows:

[0040]

[0041] According to existing literature, the preparation method of described adamantane monoquaternary ammonium salt cationic surfactant is as follows:

[0042]

[0043] (2) Degreaser BD 2 The preparation method is as follows:

[0044] ① Mix 20 parts of adamantane monoquaternary ammonium salt cationic surfactant and 8.5 parts of sodium carboxymethylcellulose into the first beaker, add 50 parts of water, heat while stirring, the stirring rate is 300ppm, and the heating temperature 42°C, the heating time is 30min, after the heating time is over, the temperature is naturally cooled to room temperature to obtain the mixed solution A;

[0045] ② Mix 16 parts of 4A zeolite and 22 parts of hydrogenated tallow alcohol polyoxyethylene (11) ether into the second beaker, add 50 parts of water, and heat while stirring. The stirri...

Embodiment 3

[0047] Embodiment 3: Degreaser BD 3 and its preparation method

[0048] (1) Degreaser BD 3 The composition and its components are as follows:

[0049]

[0050] According to existing literature, the preparation method of described adamantane monoquaternary ammonium salt cationic surfactant is as follows:

[0051]

[0052] (2) Degreaser BD 3 The preparation method is as follows:

[0053] ① Mix 20 parts of adamantane monoquaternary ammonium salt cationic surfactant and 12.5 parts of sodium carboxymethylcellulose into the first beaker, add 55 parts of water, heat while stirring, the stirring rate is 320ppm, and the heating temperature 43°C, the heating time is 25min, after the heating time is over, the temperature is naturally cooled to room temperature to obtain the mixed solution A;

[0054] ② Mix 12 parts of 4A zeolite and 26 parts of hydrogenated tallow alcohol polyoxyethylene (11) ether into the second beaker, add 55 parts of water, and heat while stirring. The sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| oil removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com