Graphite composite material, preparation method and application thereof

A technology of composite materials and graphite, which is applied in the direction of electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of unfavorable material rate performance and low temperature performance, improvement, poor conductivity, etc., to achieve improved cycle performance and high Li+ conduction performance, rate capability, and low-temperature performance enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

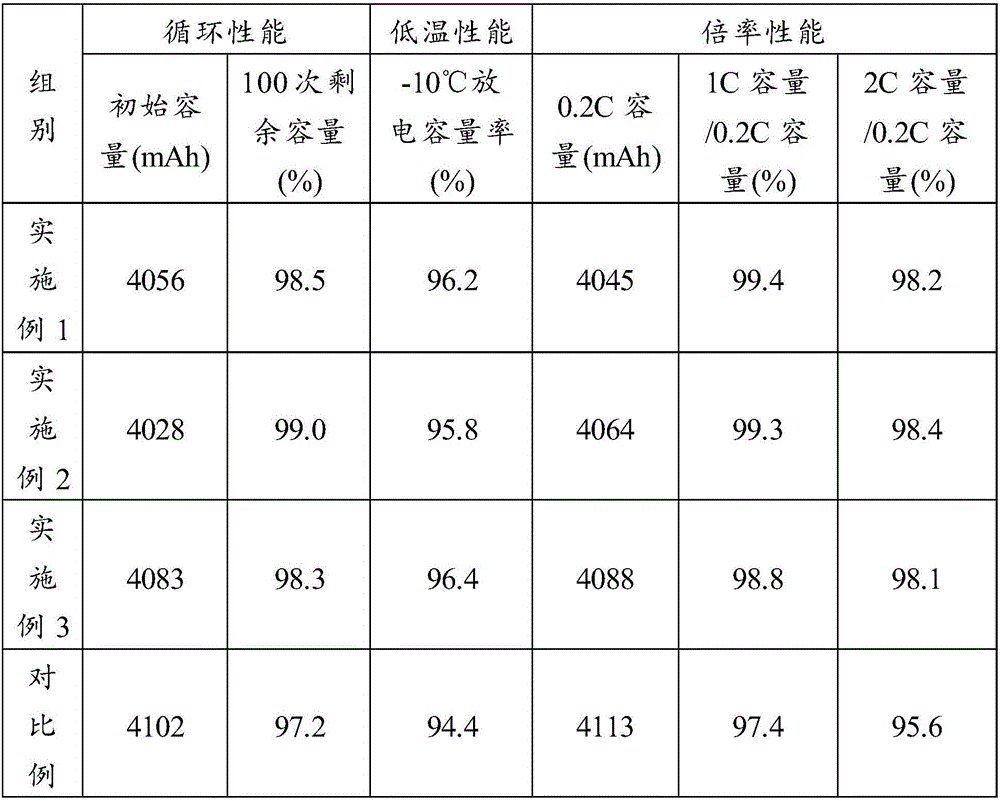

Examples

preparation example Construction

[0029] The application also provides a preparation method of graphite composite material, comprising:

[0030] Under a protective atmosphere, the cladding layer raw material containing soluble titanium source, lithium source, graphite and solvent are mixed, heated and then calcined to obtain graphite composite material.

[0031] In the process of preparing the graphite composite material, in order to make the reaction fully proceed, the process of preparing the graphite composite material can be carried out according to the following process:

[0032] Mixing the graphite material with a solution of coating layer raw materials containing a soluble titanium source, and stirring to obtain a graphite material coated with titanium oxide on the surface;

[0033] The graphite material obtained above is mixed with a solution containing a lithium source, dried and calcined in sequence after stirring to obtain a graphite composite material.

[0034] According to the present invention, ...

Embodiment 1

[0043] Weigh 10g of commercial negative electrode graphite material and place it in a solution containing 1g TiOSO 4 dilute H 2 SO 4 (concentration 0.015mol / L) in 200mL aqueous solution, using propeller stirring method to stir evenly, add 0.17g calcium oxide (CaO) at the same time, stir thoroughly for 3h; root remains; at this point, the surface is coated with TiO(OH) 2 Graphite anode material, converted to TiO 2 Calculate, the mass ratio of graphite surface coating is 5wt%;

[0044] Place the obtained transition product in 20mL of 0.31mol / L LiOH solution prepared in advance, and then place it in a ball mill for ball milling for 2h, remove the slurry and dry it, and then calcinate it at 700°C under an inert atmosphere of nitrogen 2h, the graphite anode material coated with lithium-rich LTO was obtained. During the preparation of graphite anode materials, the reactions mainly include: H 2 SO 4 +CaO=CaSO 4 +H 2 O, TiOSO 4 +2H 2 O=TiO(OH) 2 +H 2 SO 4 , 5TiO(OH) 2 +...

Embodiment 2

[0046] Take by weighing 10g of commercial negative electrode graphite material and be placed in the solution that has 3.4g Ti(OC 4 h 9 ) 4 Magnetically stir in 80mL ethanol solution for 0.5h to make the stirring fully uniform, then transfer the reactant to a solvothermal reaction kettle, and react at 150°C for 3h, so that the graphite surface is coated with a layer of amorphous TiO 2 ,TiO 2 The coating amount is 8%. Mix the obtained reactant with 20mL of 0.4mol / L LiOH ethanol solution, and carry out sufficient magnetic stirring. After drying at 150°C for 2h, under the inert atmosphere of N2 gas, carry out 650°C After 3h of heat treatment, the graphite anode material coated with LTO was obtained. During the preparation of graphite anode materials, the reactions mainly include: Ti(OC 4 h 9 ) 4 = TiO 2 +2C 4 h 9 OC 4 h 9 ;5TiO 2 +4LiOH=Li 4 Ti 5 o 12 +2H 2 O.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com