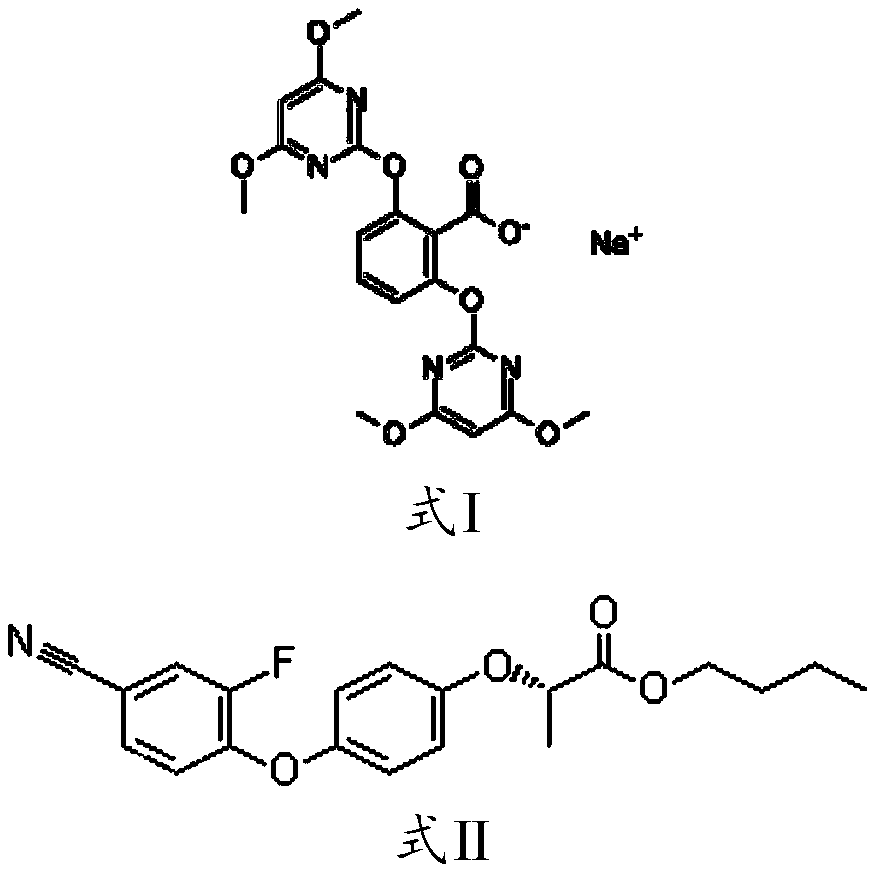

A kind of bispyribac-cyhalofop-butyl suspoemulsion and preparation method thereof

A technology of cyhalofop-fop and bispyribac, which is applied in the field of bispyribac-cyhalofop-emulsion suspoemulsion and its preparation, can solve problems such as delamination instability, environmental pollution, and influence on drug efficacy, and achieve improved safety and efficacy, improve weed control effect, improve the effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

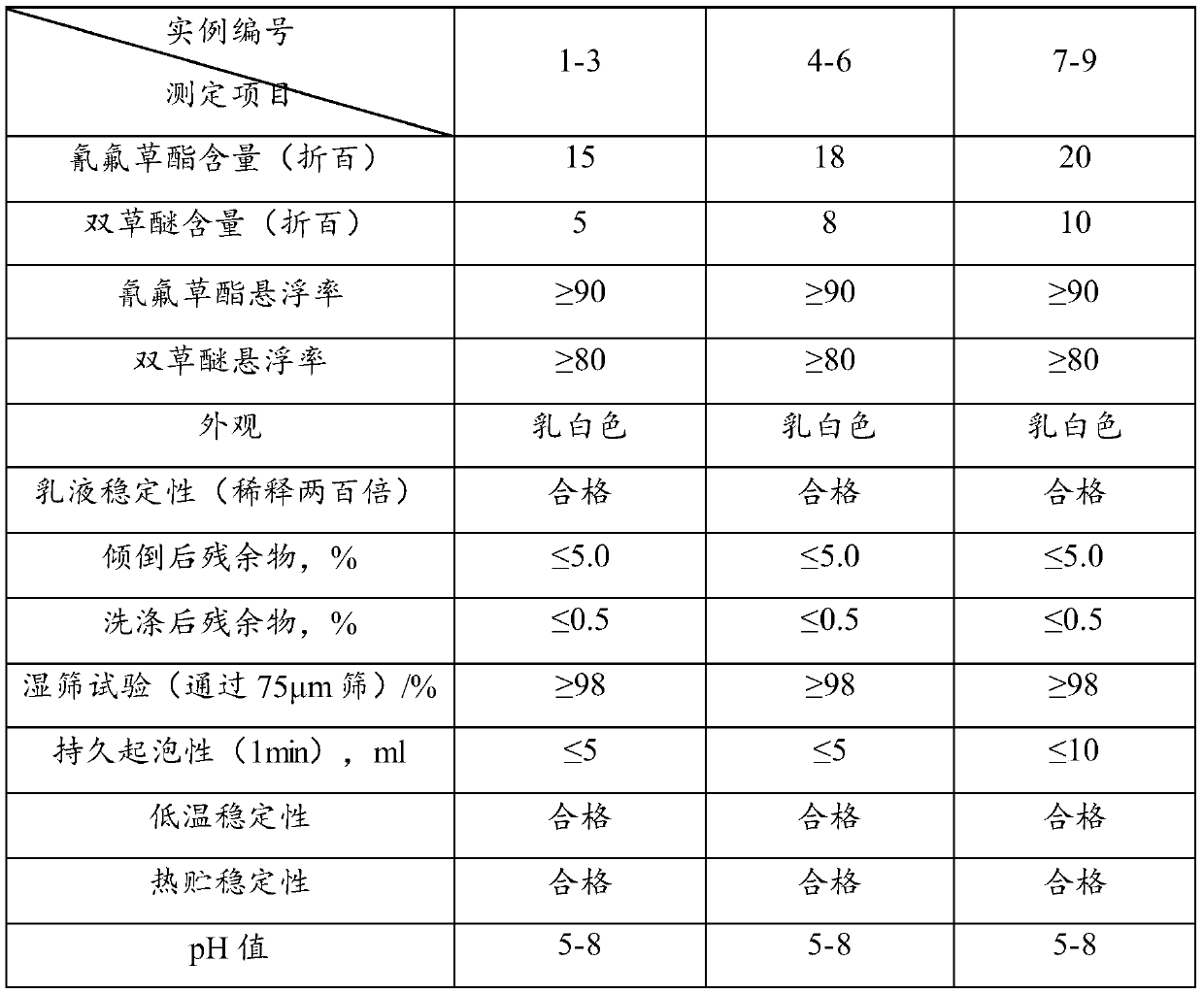

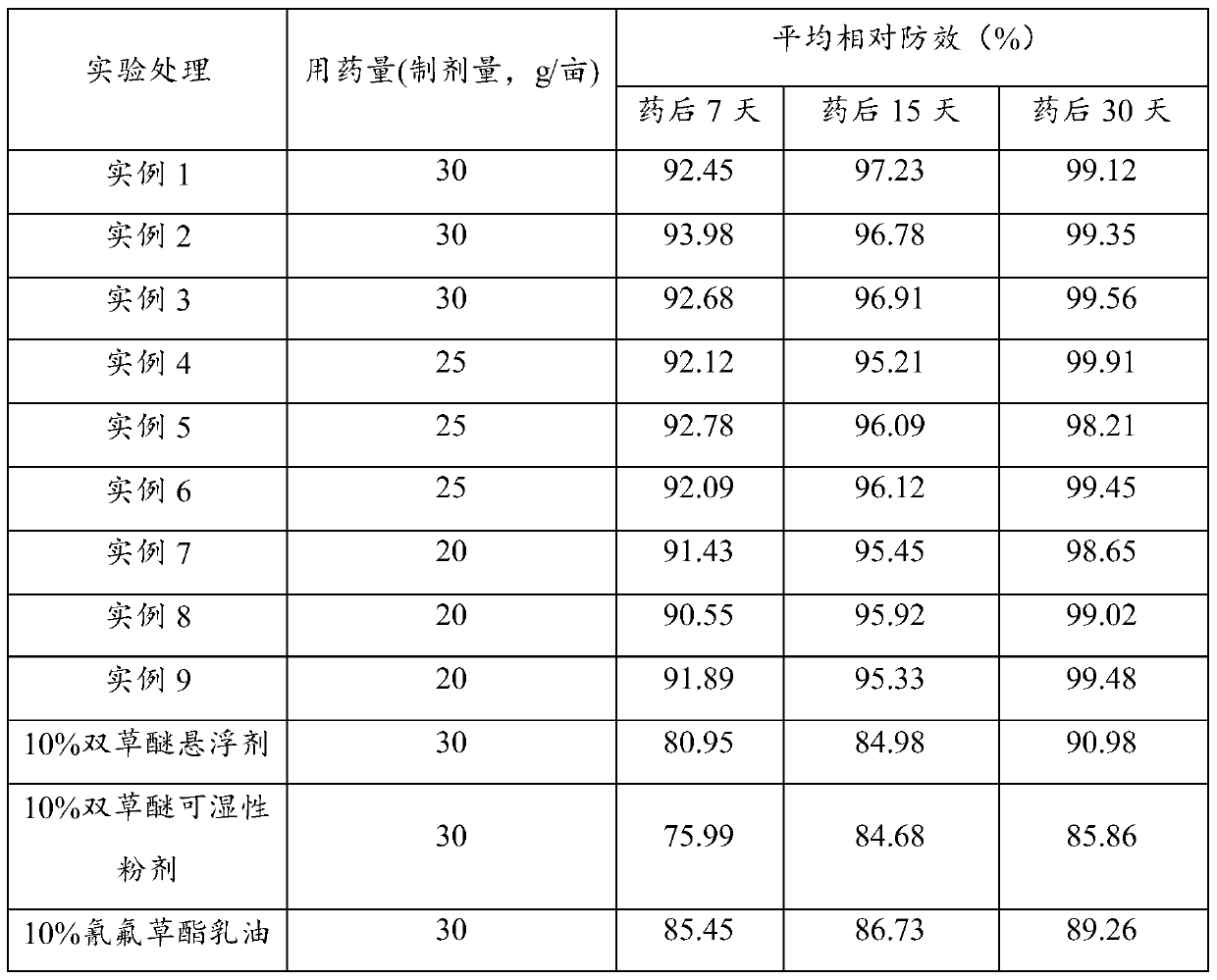

Embodiment 1

[0037] After adding 150# solvent naphtha 150g in the shear kettle, then add 156.3g of the former medicine of cyhalofop-ethyl (effective content 96%), emulsifier alkylphenol polyoxyethylene (9) ether 10g, wetting agent dodecane Calcium phenyl sulfonate 10g, fatty alcohol polyoxyethylene ether 10g, dispersant sodium lignosulfonate 20g, after mixing and stirring until transparent, add 550.1g of deionized water while stirring, then add bispyribac Content 96%) 52.1g, thickening agent xanthan gum 10g, antifreeze agent ethylene glycol 30g, long-chain alcohol defoamer 0.5g and pH regulator sodium acetate 1g, mix, stir, in high-speed shearing machine 1500~10000 Cut for 10 to 40 minutes at the speed of rpm, and then grind to particle size D with a sand mill 90 When the thickness is smaller than 3 μm, the suspoemulsion of bispyribac and cyhalofop-fop is prepared.

Embodiment 2

[0039]After adding 150g of 200# solvent oil in the shearing kettle, add 156.3g of the former drug of cyhalofop-ethyl (effective content 96%), emulsifier castor oil polyoxyethylene (10) ether 25g, wetting agent alkyl succinic acid Sodium fat sulfonate 35g, dispersant (NNO) 35g, after mixing and stirring until transparent, add 508.1g of deionized water while stirring, then add 52.1g of bispyribac-ether technical (effective content 96%), thickener silicon 7.5g of magnesium aluminum oxide, 20g of antifreeze glycerin, 1g of polyglycerin defoamer and 10g of pH regulator triethanolamine, mix and stir, and cut 10 to 40 Minutes, and then grind to particle size D by sand mill 90 When the thickness is smaller than 3 μm, the suspoemulsion of bispyribac and cyhalofop-fop is prepared.

Embodiment 3

[0041] After adding turpentine-based vegetable oil 150g in the shear kettle, add the former medicine of cyhalofop-ester (effective content 96%) 156.3g, emulsifier phenylethylphenol polyoxyethylene ether 25g, wetting agent alkyl sulfosuccinate Sodium phosphate 35g, dispersant alkylphenol polyoxyethylene ether phosphate 15g, polycarboxylate 20g, after mixing and stirring until transparent, add 508.1g of deionized water while stirring, then add the former medicine of bispyribacin (effective content 96%) 52.1g, thickener xanthan gum 2g, magnesium aluminum silicate 5.5g, antifreeze agent ethylene glycol 20g, organosilicon type defoamer 1g and pH adjuster triethanolamine 10g, mix, stir, in high speed shear Cutting machine at 1500-10000 rev / min for 10-40 minutes, then grind to particle size D by sand mill 90 When the thickness is smaller than 3 μm, the suspoemulsion of bispyribac and cyhalofop-fop is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com