Calcium carbonate particles and preparation method thereof

A technology of calcium carbonate and granules, which is applied in the field of medicine, can solve problems such as tablet hardness and disintegration uncertainty, high technical requirements for operators, and controllability of uncomfortable quality, so as to reduce the risk of cross-contamination and reduce energy consumption. consumption, good fluidity and compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

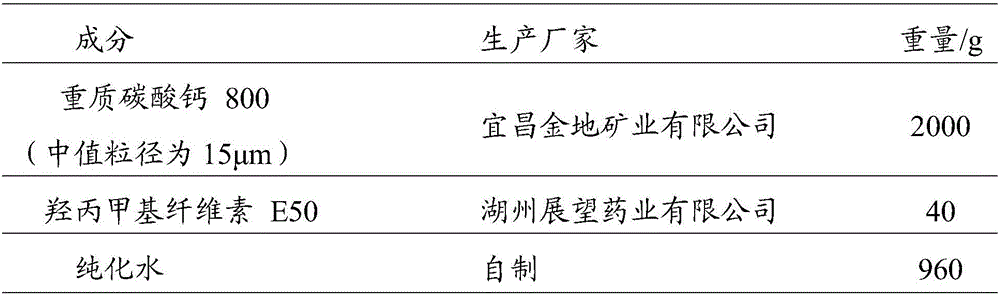

[0030] The formula composition of the calcium carbonate granule of the present embodiment is as shown in table 1:

[0031] Table I

[0032]

[0033] Preparation method: Weigh the materials according to the amounts shown in Table I, heat the purified water to 80°C, slowly add hydroxypropylmethylcellulose E50 into the hot purified water, add while stirring to obtain a binding solution, and cool to Standby at room temperature; set the inlet air temperature of the multifunctional fluidized bed (fluidized bed one-step granulator) to 60°C, and the air volume of the fan to 60m 3 / hr, preheat for 5 minutes, then add the prescribed amount of ground calcium carbonate 800 into the multifunctional fluidized bed for fluidization and preheat for 5 minutes; set the air volume of the fan to 60m 3 / hr, the air inlet temperature is 60°C, the atomization pressure is 1.6kg / ㎡, the liquid supply speed is 10rpm, and the bonding liquid is sprayed onto the calcium carbonate powder at a uniform and...

Embodiment 2

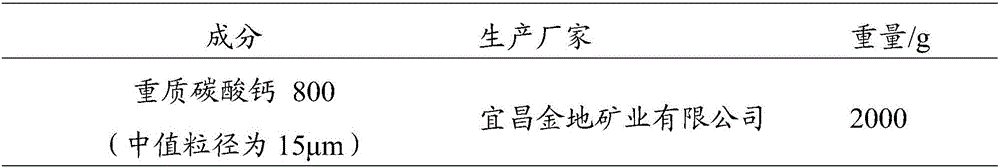

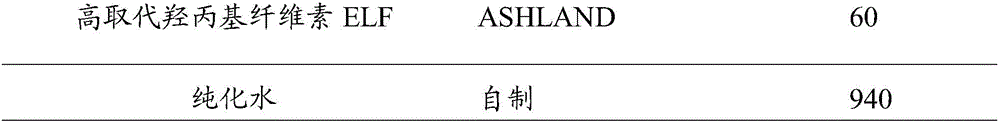

[0035] The formula composition of the calcium carbonate granule of the present embodiment is as shown in table II:

[0036] Table II

[0037]

[0038]

[0039] Preparation method: Weigh the materials according to the amounts shown in Table II, heat the purified water to about 80°C, add high-substituted hydroxypropyl cellulose ELF to the hot purified water, add while stirring to obtain a binding solution, and cool to Standby at room temperature; set the inlet air temperature of the multifunctional fluidized bed (fluidized bed one-step granulator) to 60°C, the air volume of the fan to 60m3 / hr, preheat for 5 minutes, and then add the prescribed amount of ground calcium carbonate 800 Fluidize in the multifunctional fluidized bed and preheat for 5 minutes; set the air volume of the fan to 60m 3 / hr, the air inlet temperature is 60°C, the atomization pressure is 1.6kg / ㎡, the liquid supply speed is 10rpm, and the bonding liquid is sprayed onto the calcium carbonate powder at a...

Embodiment 3

[0041] The formula composition of the calcium carbonate granule of the present embodiment is as shown in table III.

[0042] Table III

[0043]

[0044] Preparation method: Weigh the materials according to the amounts shown in Table III, add polyvinylpyrrolidone K29 / 32 into purified water, add while stirring, and wait until the solution is transparent and clear to obtain a bonding solution for use; set up a multifunctional fluidized bed (Fluidized bed one-step granulator) The air inlet temperature is 60°C, and the air volume of the fan is 60m 3 / hr, preheat for 5 minutes, then add the prescribed amount of ground calcium carbonate 800 into the multifunctional fluidized bed for fluidization and preheat for 5 minutes; set the air volume of the fan to 60m 3 / hr, the air inlet temperature is 60°C, the atomization pressure is 1.6kg / ㎡, the liquid supply speed is 10rpm, and the bonding liquid is sprayed onto the calcium carbonate powder at a uniform and constant speed through the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com