Lithium ionic sieve adsorbent with self-cleaning function and preparation method and application thereof

An adsorbent, lithium ion technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of poor lithium adsorption stability and short service life, and improve conductivity and service life. , the effect of increasing wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

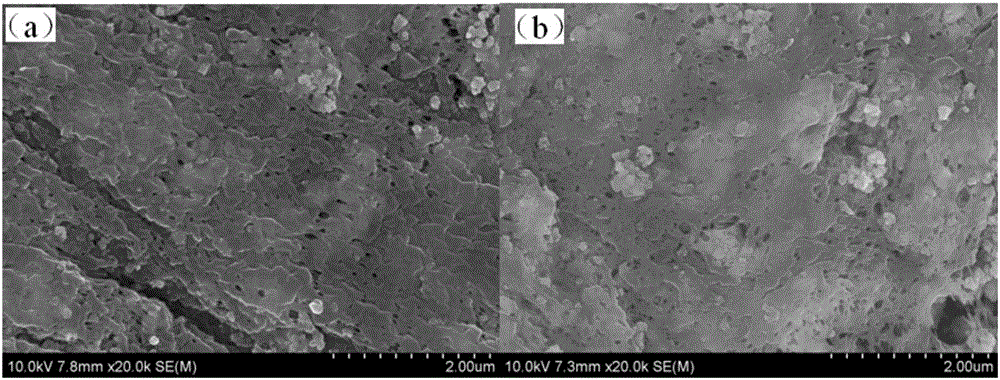

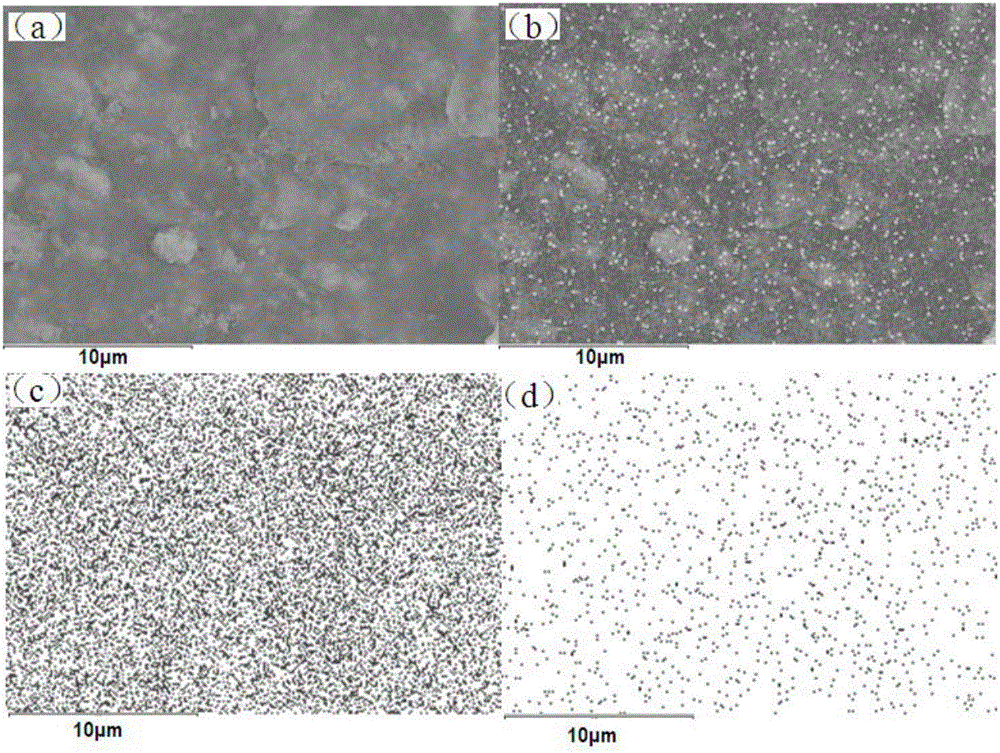

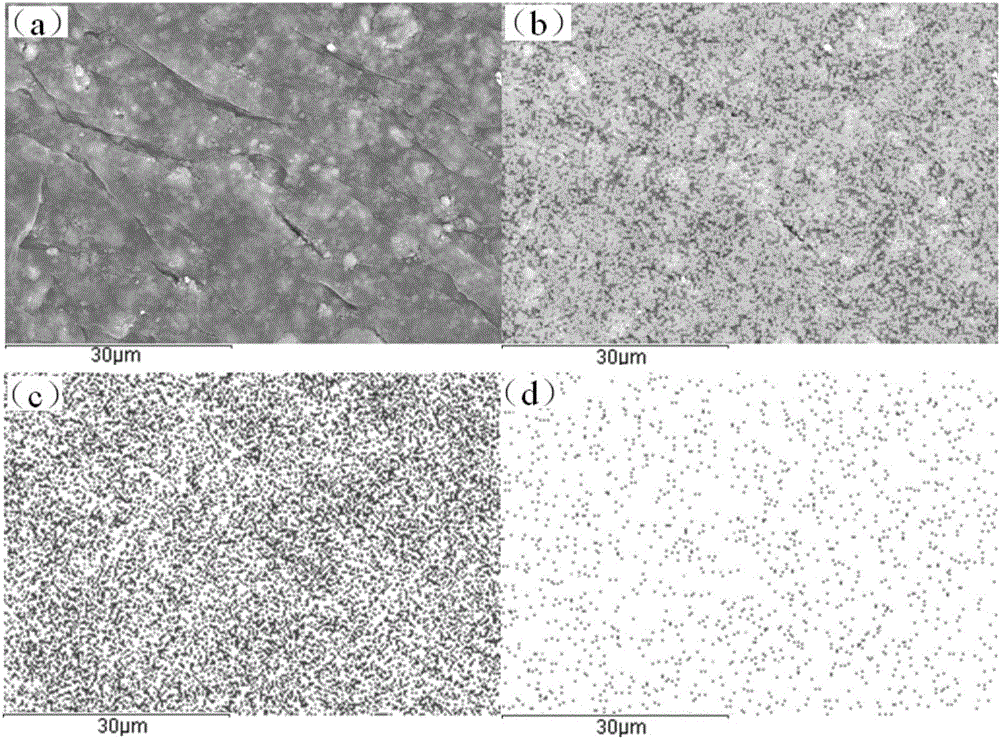

[0027] Under a nitrogen atmosphere, weigh 10ml tetrahydrofuran, add 1.185g titanium isopropoxide, and weigh 33.3g Li 1.6 mn 1.6 o 2 Add the powder into it, and then use a magnetic stirring device to mix evenly. After stirring for 2-4 hours, place it in a planetary ball mill for ball milling for 8-12 hours to obtain a brown viscous suspension. The suspension was placed in a dry blast box at 60-80 °C to make it completely dry. After cooling, take out the agglomerated, brown powder and grind it in a mortar until pulverized. Place the ground powder in a high-temperature calcination furnace and calcinate at 300–350°C for 3–12 h to obtain titanium dioxide-coated Li 1.6 mn 1.6 o 2 Powder, the powder is light brown, not agglomerated, has poor fluidity, and its physical properties are consistent with those without coating. Take 5.88g of polyvinyl chloride particles and 34.3g of sintered Li 1.6 mn 1.6 o 2 Powder, dissolved in 100 ~ 200 ml of dimethylformamide, to obtain a brow...

Embodiment 2

[0033] Under a nitrogen atmosphere, weigh 30 ml of absolute ethanol, add 4.257 g of tetrabutyl titanate, and then weigh 66.6 g Li 1.6 mn 1.6 o 2 Add the powder into it, and then use a magnetic stirring device to mix evenly. After stirring for 2-4 hours, place it in a planetary ball mill for ball milling for 8-12 hours to obtain a brown viscous suspension. The suspension was placed in a dry blast box at 60-80 °C to make it completely dry. After cooling, take out the agglomerated, brown powder and grind it in a mortar until pulverized. Place the ground powder in a high-temperature calcination furnace and calcinate at 300–350°C for 3–12 h to obtain titanium dioxide-coated Li 1.6 mn 1.6 o 2 Powder, the powder is light brown, not agglomerated, with poor fluidity, and the physical properties are consistent with those without coating. Take 11.76 g of polyvinyl chloride particles and 67.6 g of sintered Li 1.6 mn 1.6 o 2Powder, dissolved in 100 ~ 200 ml of dimethylformamide, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com