Gold-MOFs-polymer composite membrane, and production method and application thereof

A technology of polymer and composite membrane, which is applied in the direction of preparation of organic compounds, preparation of amino hydroxyl compounds, organic compound/hydride/coordination complex catalysts, etc. It can solve the problems of separation difficulties, reduce and increase separation costs, and achieve High-efficiency catalytic effect, huge application prospects, and the effect of solving recycling problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Example 1 Metal Organic Framework UiO-66-NH 2 Synthesis

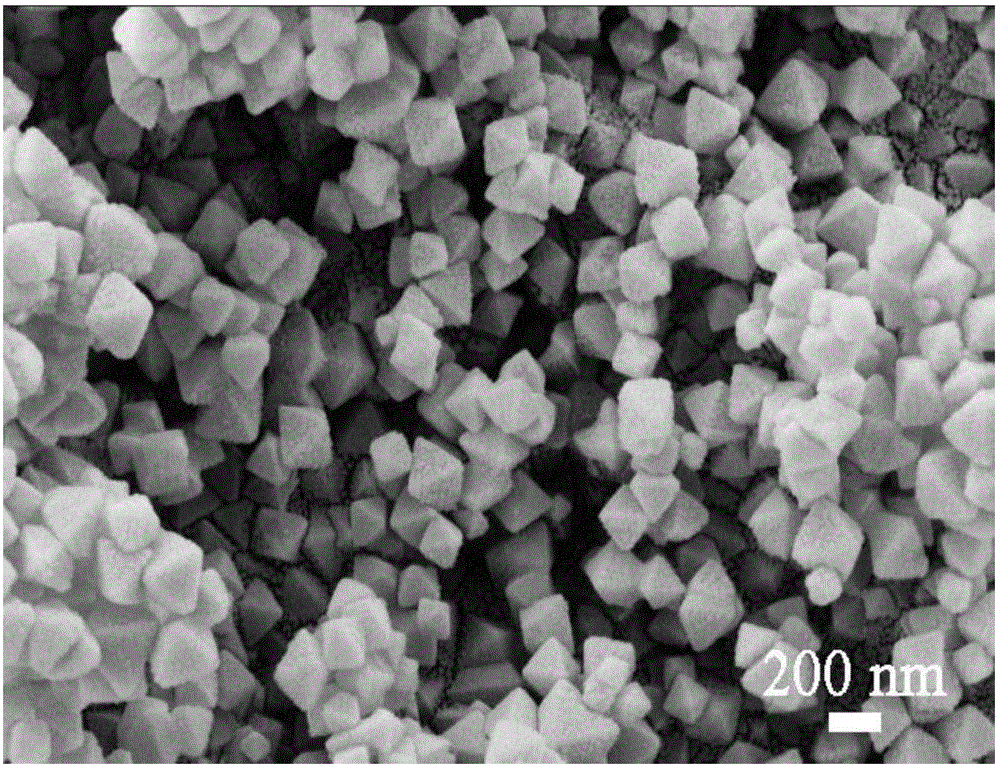

[0067] Dissolve the organic ligand 2-aminoterephthalic acid, zirconium tetrachloride, and acetic acid in N,N-dimethylformamide solvent, keep the temperature at 120°C for 24 hours, and cool down to room temperature to obtain light yellow nano-sized crystals, centrifuge, Drying; wherein the ratio of organic ligand 2-aminoterephthalic acid, zirconium tetrachloride, acetic acid and N,N-dimethylformamide solvent addition is 0.04mmol: 0.04mmol: 2mmol: 1.6ml, the obtained crystal See in description figure 1 .

Embodiment 2

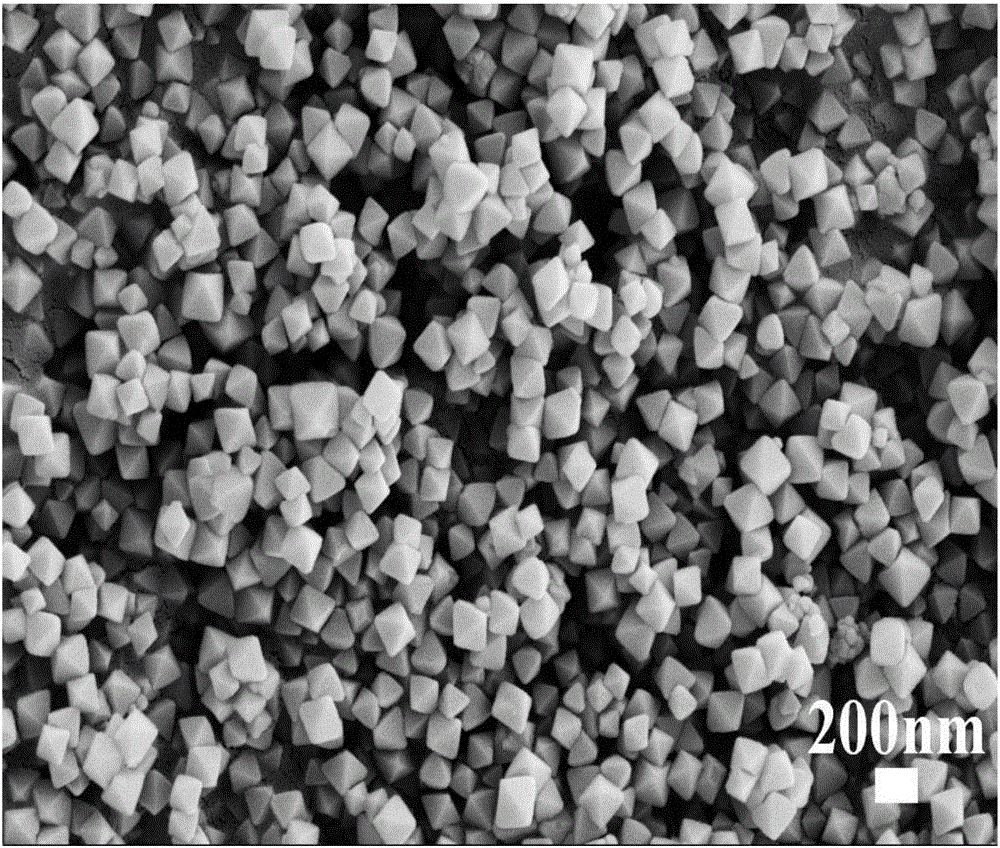

[0068] Example 2 metal organic framework UiO-66-NH 2 post-synthetic modification of

[0069] Weigh UiO-66-NH-Met crystal (0.6g, 0.002mol), methacrylic anhydride 2.356ml (2.45g, 0.016mol), triethylamine 0.279ml (0.002mol), 50ml of chloroform solution, add Into a 100ml round bottom flask, the chloroform in it was dried, the triethylamine was redistilled, heated to reflux at 55°C for 24h, and a drying device was added to the condenser. After the reaction was completed, it was cooled naturally and then centrifuged, then washed 6 times with fresh chloroform, and dried in vacuum for 5 hours at 100°C. After the treatment, it was taken out for use. figure 2 .

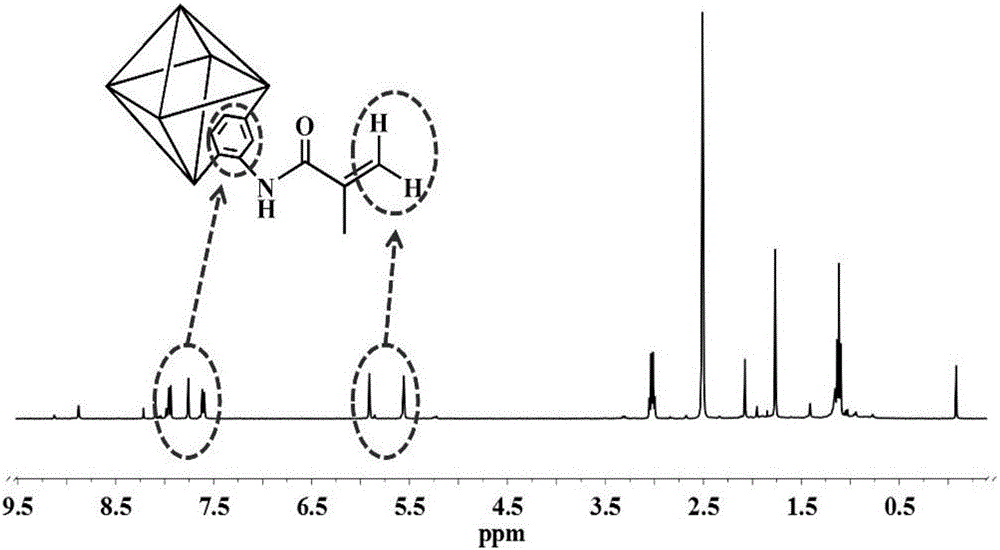

[0070] UiO-66-NH 2 During the crystal post-modification process, the yield of double bond post-modification calculated by the nuclear magnetic spectrum is as high as 98%, and the modified nuclear magnetic hydrogen spectrum is shown in image 3 .

Embodiment 3

[0071] The synthesis of embodiment 3 side chain mercaptopolysiloxanes

[0072] In a 50ml round-bottomed flask, add 5ml of mercaptopropyldimethoxymethylsilane and 2.86ml of dichlorodimethylsilane in turn, use 3ml of benzoic acid aqueous solution as the solvent, and stir for 48 hours at 50°C . After the reaction was completed, after natural cooling, 10 ml of diethyl ether was added for extraction, and liquid separation was carried out three times in succession. The diethyl ether layer was collected and rotary evaporated at a suitable temperature to obtain a colorless viscous liquid. Gel permeation chromatography (GPC) records that the number average molecular weight of mercapto silicone oil is 3500 Daltons (GPC curve sees Figure 4 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com