Chlorella vulgaris used for combined treatment of wastewater and waste gas while synchronously realizing solid carbon denitrification

A combined treatment and chlorella technology, applied in gas treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as high operating costs, limited denitrification efficiency, secondary pollution, etc., and achieve anti- Strong pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

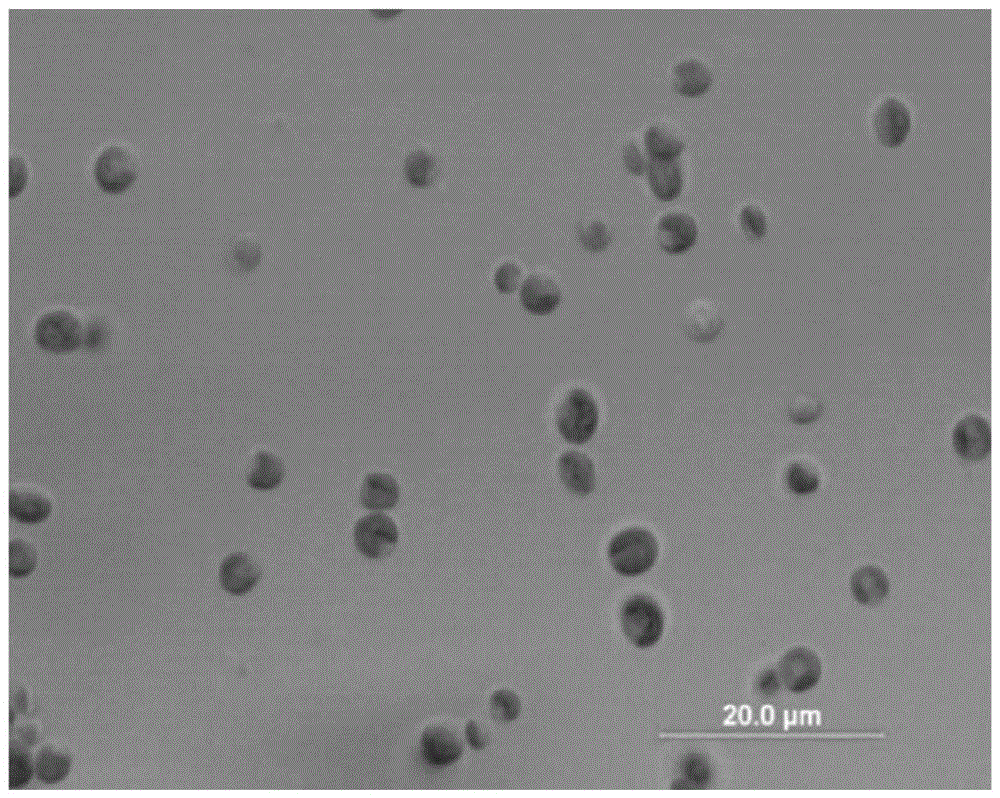

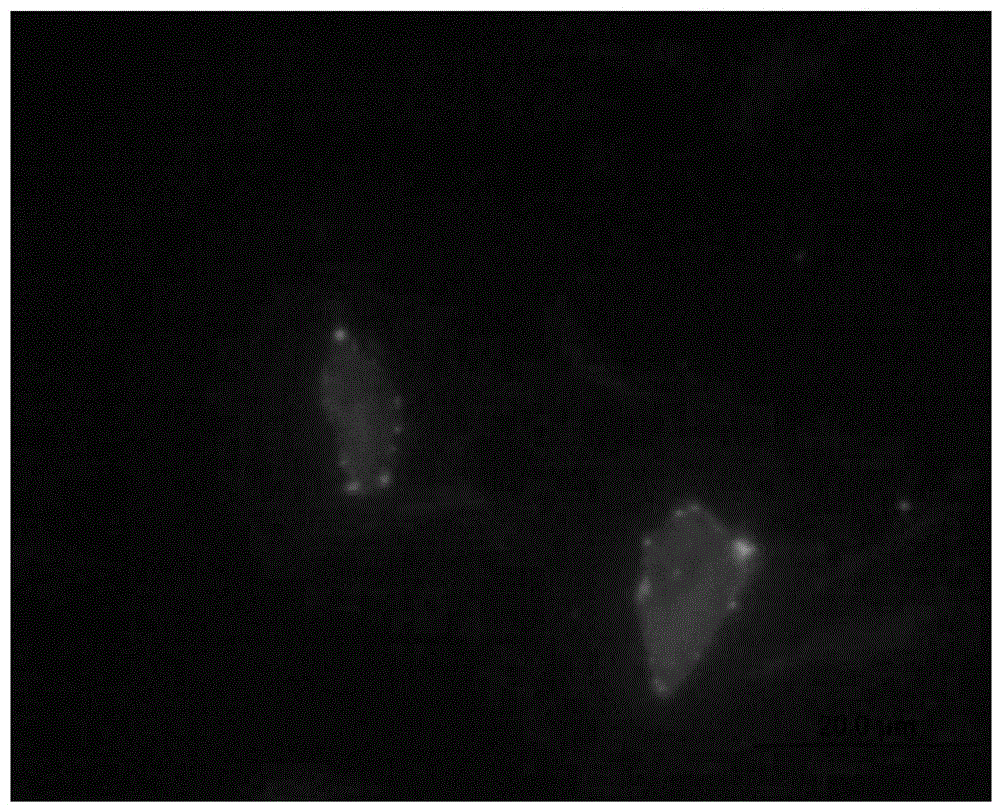

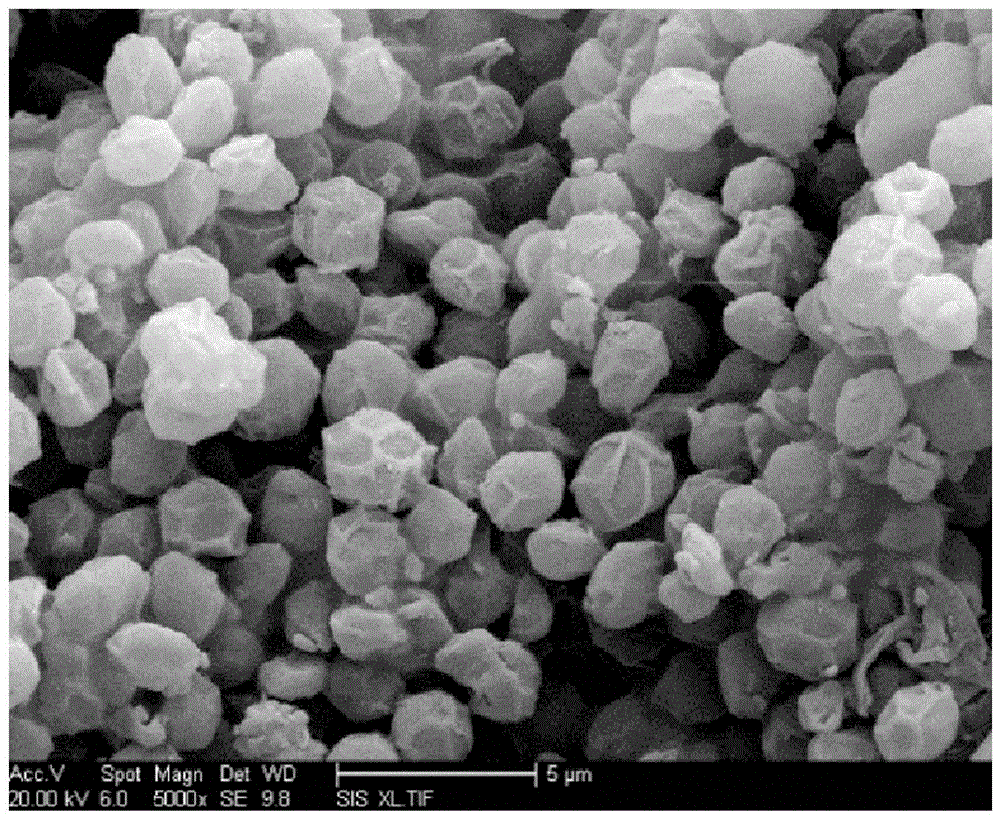

[0026] Chlorella vulgaris (Chlorella vulgaris) DH2 was inoculated into untreated soil with a pH of 8.0, a COD (Chemical Oxygen Demand) content of 310 mg / L, a total nitrogen TN content of 33 mg / L, and a total phosphorus TP content of 3.6 mg / L. In the sterilized municipal sewage, the initial inoculation amount is 5×105 / ml, under the irradiation of artificial light source, the algae can use the nutrients in the sewage to grow, the culture conditions are: light intensity 3000lux, aeration components: 5% CO2, 75ppmNO , N2 balance, aeration rate 0.1vvm, temperature 25 ℃. After the reactor was operated for one day, the average concentration of gas components at the outlet of the reactor was stable at 2.5% CO2, 35ppmNO (nitrogen balance), and after 5 days of cultivation, the density of Chlorella DH2 could reach 2.0g / L. The microalgae are collected by centrifugation, and the treated water is discharged. The removal rates of COD, TN, and TP in the treated sewage are 50.0%, 65%, and 99....

Embodiment 2

[0028] Chlorella vulgaris (Chlorella vulgaris) DH2 was inoculated into untreated soil with a pH of 8.0, a COD (Chemical Oxygen Demand) content of 310 mg / L, a total nitrogen TN content of 33 mg / L, and a total phosphorus TP content of 3.6 mg / L. In the sterilized municipal sewage, the initial inoculation amount is 5×105 / ml, under the irradiation of artificial light source, the algae grow using the nutrients in the sewage, the culture conditions are: light intensity 3000lux, aeration components: 15% CO2, 50ppmNO , N2 balance, aeration rate 0.1vvm, temperature 25 ℃. After the reactor was operated for one day, the average concentration of gas components at the outlet of the reactor was stable at 13% CO2, 19.8ppmNO (nitrogen balance), and after 5 days of cultivation, the density of Chlorella DH2 could reach 2.8g / L. The microalgae are collected by centrifugation, and the treated water is discharged. The removal rates of COD, total nitrogen TN, and total phosphorus TP in the treated s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com