Bio-preparation method for (R)-3,5-bis(trifluoromethyl) phenyl ethanol

A technology of trifluoromethyl and phenethyl alcohol, applied in the field of medicine, can solve the problems of unsuitability for industrial production, low catalytic activity, stimulation of antibiotic resistance and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

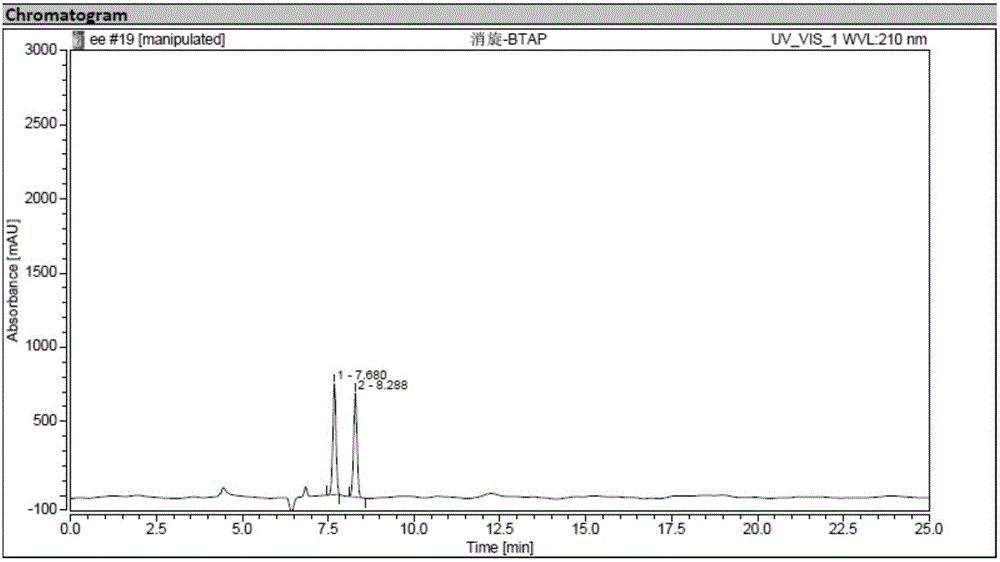

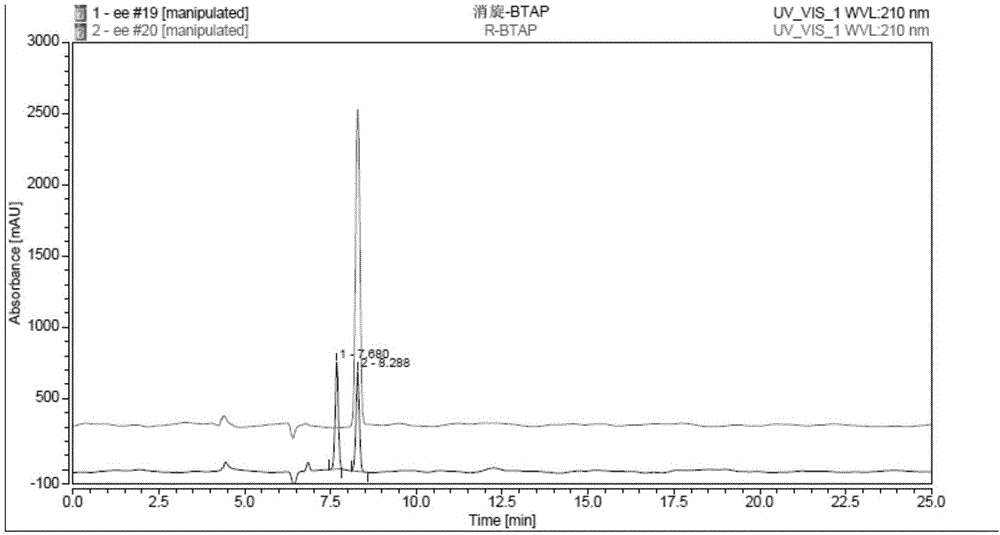

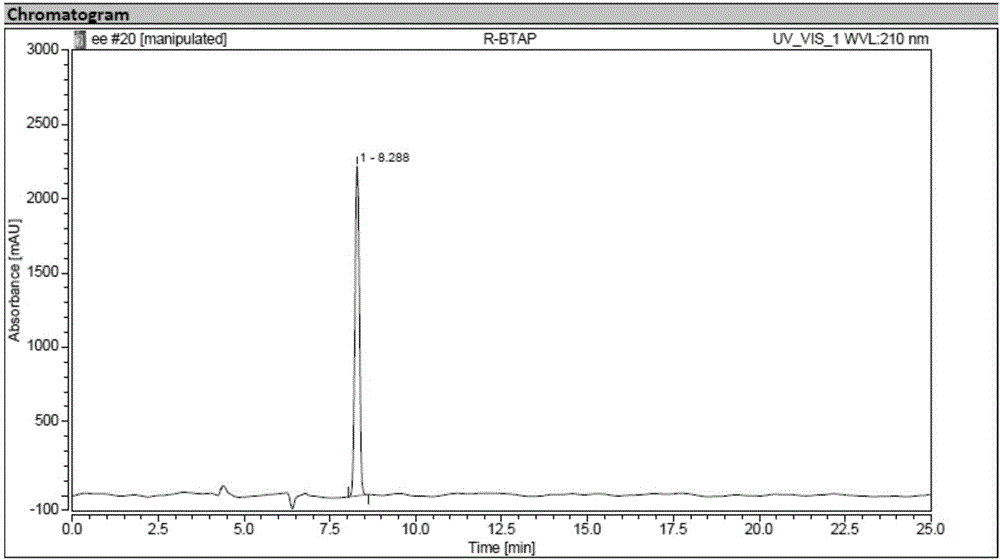

Image

Examples

preparation example Construction

[0091] The invention provides a method for preparing (R)-3,5-bis(trifluoromethyl)phenethyl alcohol, comprising the steps of:

[0092] (a) In a liquid reaction system, the compound of formula II is used as a substrate, and in the presence of a coenzyme, under the catalysis of carbonyl reductase, an asymmetric reduction reaction is carried out to form a compound of formula I, namely (R)-3,5- Bis(trifluoromethyl)phenethyl alcohol;

[0093]

[0094] Wherein, in the reaction system, the concentration of the compound of formula II is 50-1000 g / L; and

[0095] (b) optionally isolating the compound of formula I from the reaction system after the reaction in the previous step.

[0096] In the present invention, the above reaction can be coupled or not coupled with the coenzyme regeneration system.

[0097] Preferably, the above reactions are coupled with a coenzyme regeneration system in the same system, thereby further improving production efficiency, reducing production costs an...

Embodiment 1

[0139] Embodiment 1: Construction of carbonyl reductase engineering bacteria

[0140] The QNR target gene and alcohol dehydrogenase gene were entrusted to a commercial company to carry out the whole gene synthesis, cloned into the pET28a(+) vector, transformed into Escherichia coli DH5α competent cells, cultured on the plate, picked a single positive transformant colony and extracted the plasmid for sequencing After confirmation, the recombinant plasmid is extracted, introduced into BL21 (DE3) strain, cultured in LB, and genetically engineered bacteria capable of inducing the expression of recombinant carbonyl reductase and alcohol dehydrogenase are obtained.

Embodiment 2

[0141] Embodiment 2: the preparation of recombinant carbonyl reductase, alcohol dehydrogenase

[0142] Inoculate the genetically engineered bacterium stored in glycerol in the previous step into the LB liquid medium containing kanamycin, cultivate for 13 hours at 37°C and 220rpm to obtain the seed medium, and inoculate the seed culture medium in a proportion of 1.5%. On the liquid medium containing 50ug / ml kanamycin resistance, then cultivate to OD at 37℃, 220rmp 600 If the value is >2.0, add lactose with a final concentration of 1.0%, cool down to 25°C, continue to cultivate for 3 hours, add lactose with a final concentration of 0.5%, and cultivate for 20 hours, put it in a tank, and centrifuge to obtain bacteria, which is ready for biotransformation.

[0143] The medium formula is:

[0144] raw material Mass content (%) Yeast extract 2.4 soy peptone 1.2 Sodium chloride 0.3 glycerin 0.5 Dipotassium phosphate 0.2 Magnesium Sulfat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com