Composite microsphere negative electrode material with core-shell structure, preparation method and application of composite microsphere negative electrode material

A technology of negative electrode material and core-shell structure, which is applied in the field of Li1.1V0.9O2/C microsphere composite negative electrode material and its preparation, can solve the problems of initial cycle capacity loss, restriction of practical progress, high potential platform, etc., and improve the structure mode , low cost, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

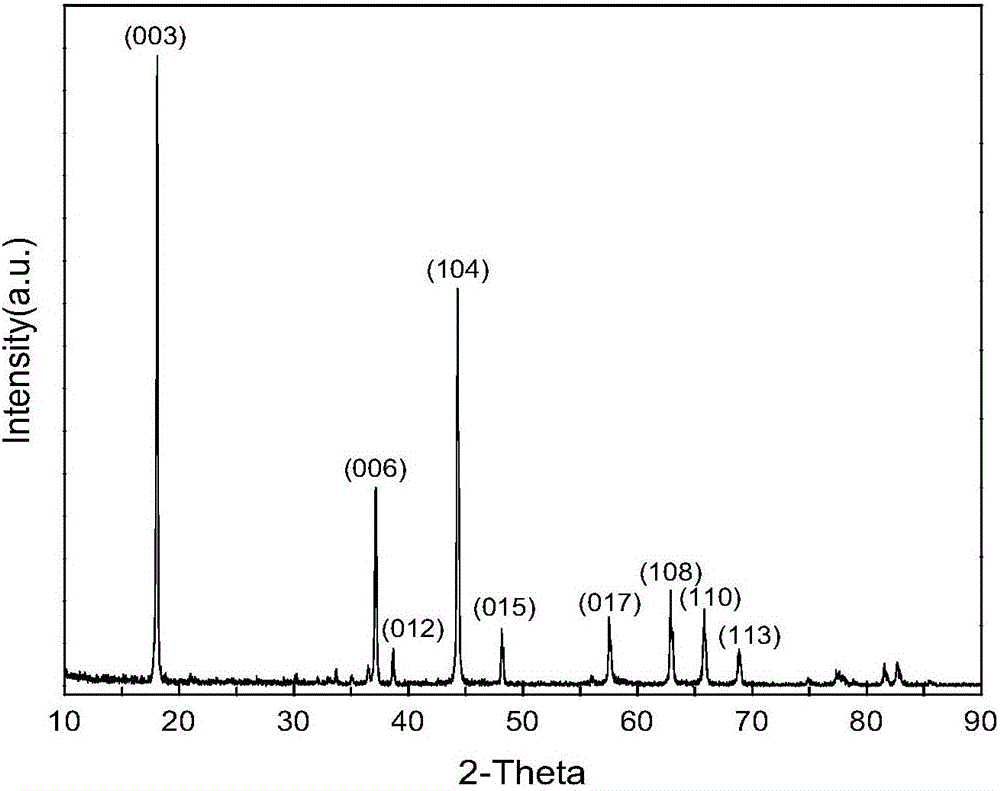

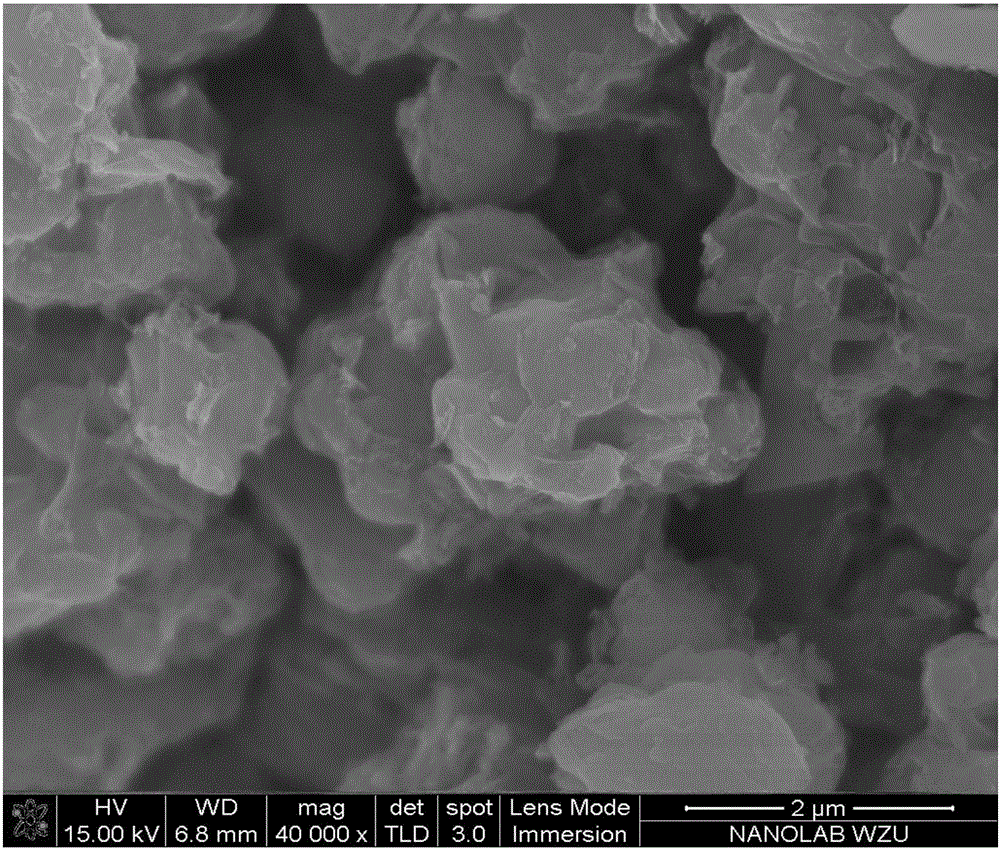

[0027] Li with core-shell structure in the present invention 1.1 V 0.9 o 2 The preparation method of / C microsphere composite negative electrode material mainly comprises the following steps:

[0028] The method comprises the following steps: dissolving a lithium source and a vanadium source with a molar ratio of 1.1:0.9 according to the element Li:V, and an auxiliary agent in absolute ethanol, and then grinding; taking out the gelatinous mixture obtained by grinding and putting it into an open In the container, the precursor is obtained after evaporation and drying; the precursor is sequentially subjected to low-temperature carbonization and high-temperature synthesis in an inert or reducing atmosphere to obtain the Li with core-shell structure. 1.1 V 0.9 o 2 / C microsphere composite anode material.

[0029] more specific:

[0030] S1. Weigh and mix the lithium source and vanadium source according to the element Li:V molar ratio of 1.1:0.9, dissolve the lithium vanadium...

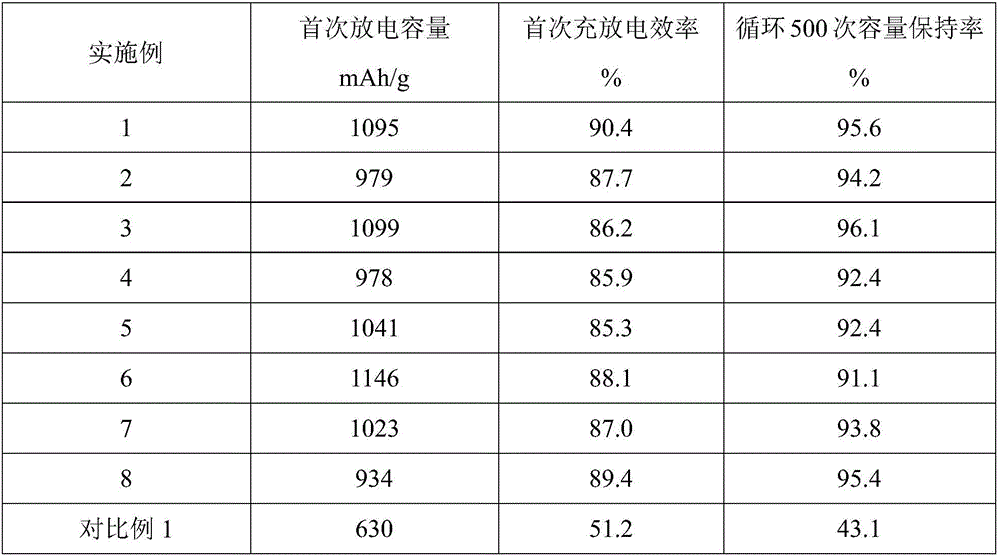

Embodiment 1

[0036] Li with a core-shell structure 1.1 V 0.9 o 2 The preparation method of / C microsphere composite negative electrode material comprises the following steps:

[0037] The synthetic raw material lithium vanadium mixture (CH 3 COOLi, V 2 o 3 ) and polyvinyl alcohol weigh 40 grams of the total mass according to the mass ratio of 80:20, and the lithium vanadium mixture is Li: CH with a V molar ratio of 1.1:0.9 3 COOLi, V 2 o 3 32 grams of the mixture was dissolved in 40 milliliters of absolute ethanol, and 8 grams of polyvinyl alcohol was added to completely disperse the reactant in ethanol. After ball milling on a planetary ball mill at a speed of 300 rpm for 4 hours, a gel-like mixture was obtained. The gel-like mixture was placed in an open glass dish, evaporated and dried at 80° C. for 48 hours to obtain a precursor. Then, the precursor was carbonized at a low temperature of 500°C for 3 hours in an argon atmosphere, then synthesized at a high temperature of 1050°C ...

Embodiment 2

[0041] Li with a core-shell structure 1.1 V 0.9 o 2 The preparation method of / C microsphere composite negative electrode material comprises the following steps:

[0042] The synthetic raw material lithium vanadium mixture (CH 3 COOLi, V 2 o 5 ) and polyvinyl alcohol weigh 40 grams of the total mass according to the mass ratio of 80:20, and the lithium vanadium mixture is Li: CH with a V molar ratio of 1.1:0.9 3 COOLi, V 2 o 5 Mixture 32 grams, be dissolved in the dehydrated alcohol of 40 milliliters, and add polyvinyl alcohol 8 grams, make reactant be completely dispersed in ethanol, obtain colloidal mixture after 4 hours with the rotating speed ball mill of 300 rev / mins on the planetary ball mill, The gel-like mixture was placed in an open glass dish, evaporated and dried at 80°C for 36 hours to obtain the precursor. Then the precursor was carbonized at a low temperature of 600°C for 2 hours in an argon atmosphere, then synthesized at a high temperature of 1100°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com