Zirconium-doped cerium-manganese oxide catalyst as well as preparation and application

A technology of catalysts and oxides, which is applied in the field of zirconium-doped cerium-manganese oxide catalysts and its preparation, can solve the problems of alkali metal poisoning, poisoning, and affecting the service life of catalysts, and achieve improved fluidity, low cost, and improved low-temperature catalytic efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

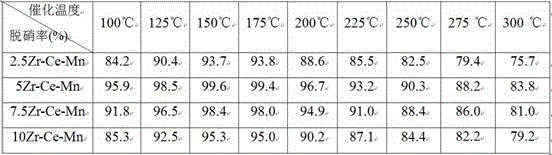

Embodiment 1

[0013] Take by weighing 8.95 grams of 50% manganese nitrate solution, 10.85 grams of cerium nitrate and 0.54 grams of zirconium nitrate are dissolved in 200 milliliters of deionized water, add dropwise 40 milliliters of 1.95 mol / liter ammonium carbonate aqueous solution while stirring at room temperature, continue to stir and filter after 2 hours, The obtained solid was dried in an oven at 70°C for 12 hours, and then calcined in a muffle furnace at 500°C for 4 hours to obtain a zirconium-doped cerium-manganese catalyst 2.5Zr-Ce-Mn.

Embodiment 2

[0015] Compared with Example 1, the difference is that the quality of zirconium nitrate is 1.07 grams, the concentration of ammonium carbonate is 2.02 mol / liter, the amount of other materials and operating conditions are the same as in Example 1, and the zirconium-doped cerium-manganese catalyst 5.0Zr- Ce-Mn.

Embodiment 3

[0017] Compared with Example 1, the difference is that the quality of zirconium nitrate is 1.61 g, the concentration of ammonium carbonate is 2.1 mol / liter, and the amount of other materials and operating conditions are the same as in Example 1 to obtain 7.5Zr-Ce-Mn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com