Preparation method of high-crystallinity hexagonal boron nitride powder

A boron nitride powder, high crystallinity technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of low crystallinity of h-BN

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

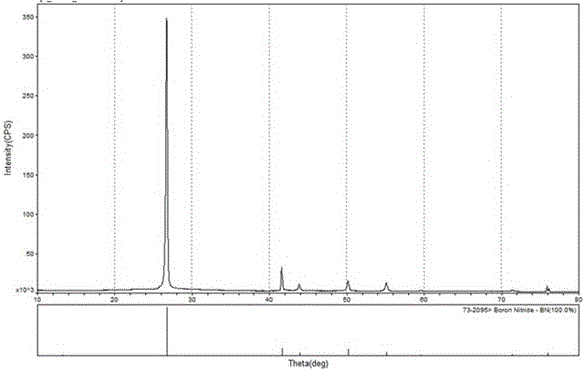

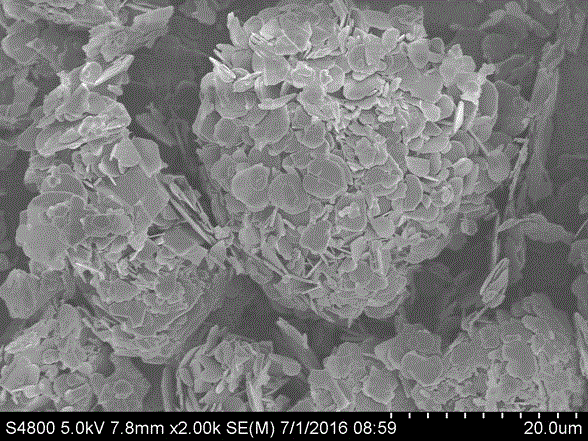

[0013] The industrial-grade urea is purified to analytical purity by recrystallization, ground to below 200 mesh, and dried before use. The urea after the above treatment is uniformly mixed according to the mass ratio of boric acid and urea at a ratio of 1:0.5, and put into a silicon nitride crucible for nitriding in a nitrogen atmosphere. The specific process parameters are to first raise the temperature to 850°C, hold it for 2 hours, and carry out nitriding, then raise the temperature to 1600°C, hold it for 2 hours, so as to improve the crystallinity. At the end of the final incubation period, two air changes were performed. After grinding the nitrided powder, XRD (X-ray Diffraction, X-ray diffraction) was used to measure the h-BN crystal phase content as 100% ( figure 1 ), so washing and purification are not required. The graphitization index of the sample was calculated to be 5.6. figure 2 Shown is the powder morphology obtained by SEM test, it can be seen that the lam...

Embodiment 2

[0015] The industrial-grade urea is purified to analytical purity by recrystallization, ground to below 200 mesh, and dried before use. The urea after the above treatment is weighed according to the ratio of boric acid to urea mass ratio of 1:4, and after adding 10% sodium azide of the total mass of urea and boric acid, mix evenly, put it into a boron nitride crucible, and in a nitrogen atmosphere Nitriding is carried out. The specific process parameters are to first raise the temperature to 900°C, hold it for 1 hour, and carry out nitriding, then raise the temperature to 2000°C, hold it for 2 hours, so as to improve the crystallinity. At the end of the final incubation period, two air changes were performed. Because there is borax in the raw material, there will be a certain amount of Na in the reaction product 2 O, therefore, after grinding the nitrided powder, wash it twice quickly with deionized water at 30°C, wash it with absolute ethanol, and dry it. The h-BN crystal ...

Embodiment 3

[0017] The industrial-grade urea is purified to analytical purity by recrystallization, ground to below 200 mesh, and dried before use. The urea after the above treatment is uniformly mixed according to the mass ratio of boric acid and urea at a ratio of 1:2, and put into a silicon nitride crucible for nitriding in a nitrogen atmosphere. The specific process parameters are to first raise the temperature to 950°C, hold it for 0.5h, and carry out nitriding, then raise the temperature to 1850°C, and hold it for 2h, so as to increase the crystallinity. At the end of the final incubation period, two air changes were performed. Because there is sodium azide in the raw material, there will be a certain amount of Na in the reaction product 2 O, therefore, after grinding the nitrided powder, wash it twice quickly with deionized water at 30°C, wash it with absolute ethanol, and dry it. The h-BN crystal phase content in the sample was determined to be 100% by XRD. The graphitization i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com