A method for extracting lithium from high magnesium-lithium ratio salt lake brine

A technology of salt lake brine and high magnesium-lithium ratio, applied in the direction of improving process efficiency, etc., can solve the problems of strong corrosion of equipment and low product purity, achieve high reaction yield, easy access to reaction raw materials, and improve water-in-oil The effect of the phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

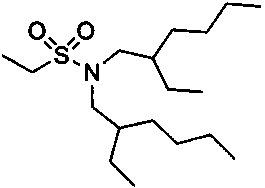

[0019] The extractant is TBP and sulfonamide compound N,N-bis-(2-ethylhexyl)ethylsulfonamide, whose structural formula is as follows:

[0020]

[0021] The synthesis method of the above-mentioned N,N-bis-(2-ethylhexyl)ethylsulfonamide: add 0.3mol of N,N-bis-(2-ethylhexyl)amine into a 1000ml three-necked flask, add 0.33mol of Ethylsulfonyl chloride, 200ml dichloromethane, stir to cool down to -5°C~0°C, add dropwise 0.3mol ethylsulfonyl chloride / 150ml methylene chloride solution, keep the system temperature below 5°C during the dropwise addition, and complete the dropwise addition , react at 0°C for 2h, add 220ml of water, extract and keep the organic phase. The organic phase was washed with alkali and acid respectively, dried with anhydrous sodium sulfate, and spin-dried to obtain the target product.

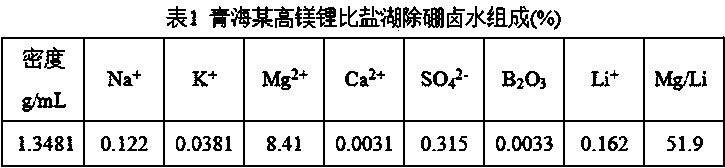

[0022] Add 1 volume of salt lake brine shown in Table 1 into a separatory funnel, add a certain amount of FeCl 3 (FeCl 3 Li in brine + The molar ratio is 1:1) as a co-extr...

Embodiment 2

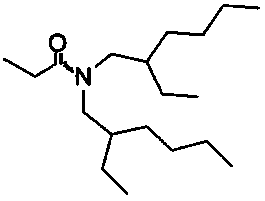

[0026] The extractant is TBP and sulfonamide compound N-methyl-N-phenylethyl ethyl sulfonamide, and its structural formula is as follows:

[0027]

[0028] Add 1 volume of salt lake brine shown in Table 1 into a separatory funnel, add a certain amount of FeCl 3 (FeCl 3 Li in brine + The molar ratio is 1:1.5) as a co-extraction agent, shake to dissolve it. Add 5 volumes of the organic phase (compared to O / A=5), wherein the volume ratio of N-methyl-N-phenylethylethylsulfonamide, TBP and 200# solvent naphtha is 4:3:3, shake for 10 After 10 minutes rest layered. Determination of Li in the equilibrium aqueous phase + , Calculate the extraction rate of lithium to be 90.96%. After washing, stripping, evaporation, decolorization, cooling, crystallization and drying, the Na in the product is measured + 、K + , Mg 2+ , Ca 2+ , SO 4 2- , B 2 O 3 The percentage contents are 0.0030%, 0.0008%, 0.0016%, 0.0005%, 0.0012%, 0.028%, respectively.

Embodiment 3

[0030] The extractant is TBP and sulfonamide compound N-methyl-N-(2-pyridine) ethyl isopropyl sulfonamide, its structural formula is as follows:

[0031]

[0032] Add 1 volume of salt lake brine shown in Table 1 into a separatory funnel, add a certain amount of FeCl 3 (FeCl 3 Li in brine + The molar ratio is 1:1.3) as a co-extraction agent, shake to dissolve it. Add 2 volumes of organic phase (compared to O / A = 2) with N-methyl-N-(2-pyridine)ethylisopropylsulfonamide, TBP and sulfonated kerosene in a volume ratio of 1:3: 6. After shaking for 10 minutes, rest and stratify. Determination of Li in the equilibrium aqueous phase + , Calculate the extraction rate of lithium to be 81.17%. After washing, stripping, evaporation, decolorization, cooling, crystallization and drying, the Na in the product is measured + 、K + , Mg 2+ , Ca 2+ , SO 4 2- , B 2 O3 The percentage contents are 0.0026%, 0.0007%, 0.0014%, 0.0005%, 0.0010%, 0.024%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com