Sputtering target, oxide semiconductor film, preparing method of sputtering target and preparing method of oxide semiconductor film

A technology of oxide semiconductors and sputtering targets, which is applied in the direction of oxide conductors, semiconductor devices, sputtering coating, etc., can solve the problems of unsuitable preparation of TFT devices, changes in performance parameters, high carrier concentration, etc., and reduce The effect of carrier concentration, good semiconductor performance, and high mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] An embodiment of the present invention provides a method for preparing a sputtering target, including:

[0029] Will In 2 o 3 Powder, CeO 2 The powder, the ZnO powder and the doped metal oxide powder are uniformly mixed to form a mixture, and the molar ratio of In:Ce:Zn in the mixture is 2:(0.5~2):1; and

[0030] The mixture is sintered at 1250°C~1650°C.

[0031] In the mixture, the atomic percentage of the doping metal element M in the total metal elements (ie In+Ce+Zn+M) is 0.5%-1%.

[0032] In this mixture, the In 2 o 3 Powder, CeO 2 The particle size of the powder, the ZnO powder and the doped metal oxide powder is preferably less than or equal to 10 microns, more preferably 0.5 microns to 2 microns.

[0033] The In 2 o 3 Powder, CeO 2 The purity of the powder, the ZnO powder and the doped metal oxide powder is preferably 3N (99.9% by mass) to 5N (99.999% by mass).

[0034] The In 2 o 3 Powder, CeO 2 The molar ratio of powder and ZnO powder is In 2 o ...

Embodiment 1

[0067] Embodiment 1: sputtering target and preparation method thereof

Embodiment 1-1

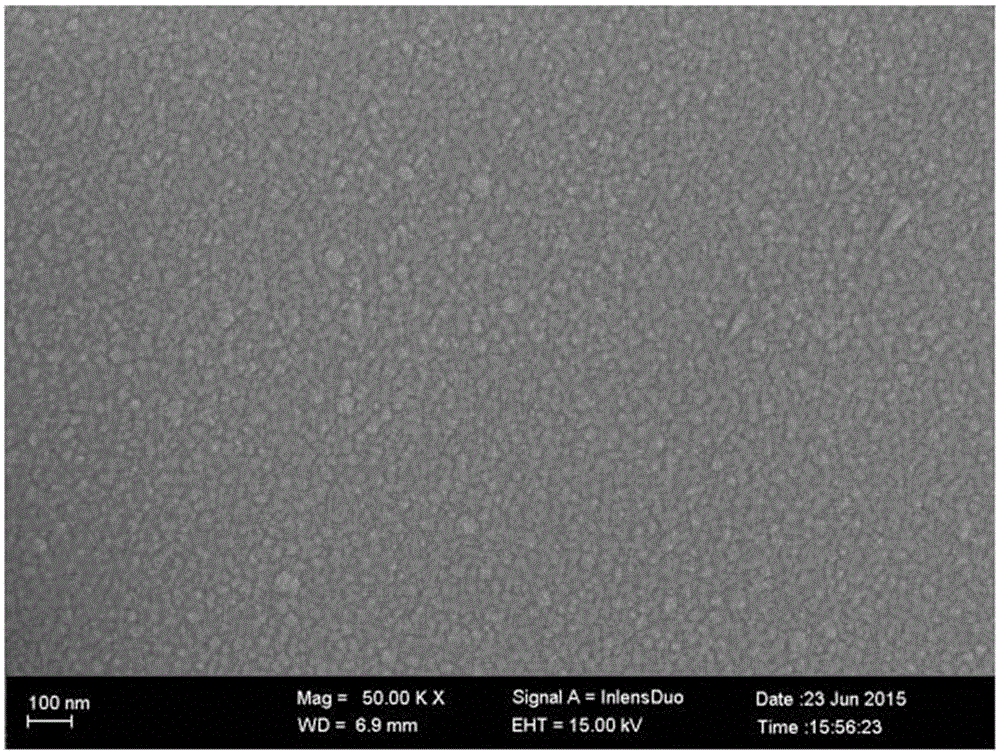

[0069] Use different doped metal oxides to make 2 kinds of sputtering targets, specifically weighing 209g In with a purity of 4N 2 o 3 Powder, 260g CeO 2 powder and 61g ZnO powder (the molar ratio of the three oxides is In 2 o 3 : CeO 2 : ZnO =1:2:1), and then weigh the doped metal oxide powder with a purity of 4N and accounting for 0.5% of the atomic percentage of the total metal elements. The doped metal oxide powder is HfO 2 and ZrO 2 . Mix the four powders in a ball mill jar. The ball milling medium is absolute ethanol, the ball milling speed is 200 rpm, and the ball milling time is 10 h. After ball milling, it was dried under the protection of Ar gas with a pressure of 1 atm and a purity of 5N for 1 h. After drying, put the powder into a hot-press sintering furnace, and carry out hot-press sintering in a high-purity Ar gas atmosphere, the sintering pressure is 50 MPa, the sintering temperature is 1350 °C, the heating rate is 15 ºC / min, and the sintering time is 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com