Bismuth metal anode for sodium/potassium ion secondary battery and ether-based electrolyte

A secondary battery, potassium ion technology, applied in the field of electrochemistry, can solve the problems of inappropriate charging and discharging platform voltage, low Coulomb efficiency, fast decay, etc., to improve rate performance and cycle stability, improve ionic conductivity, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

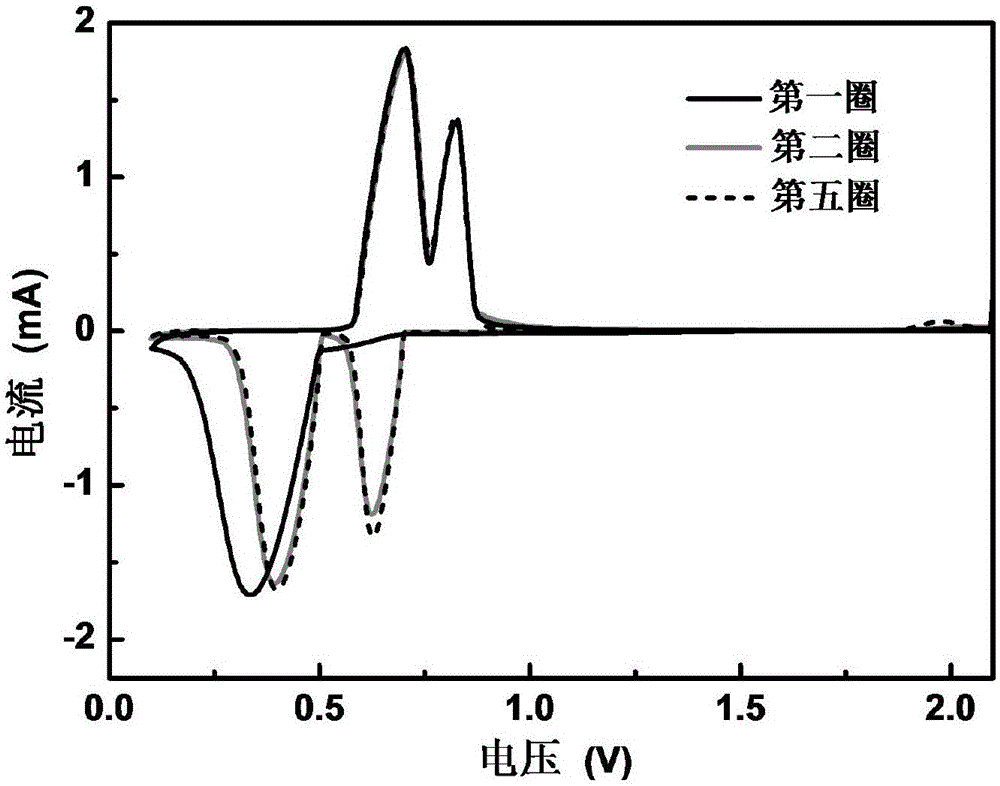

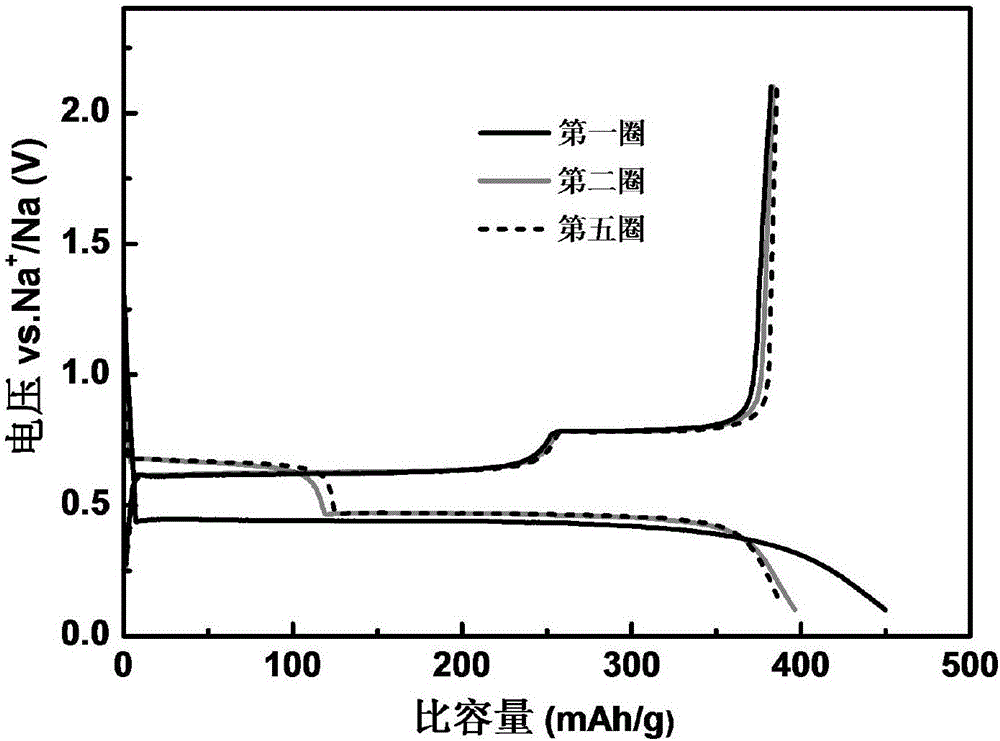

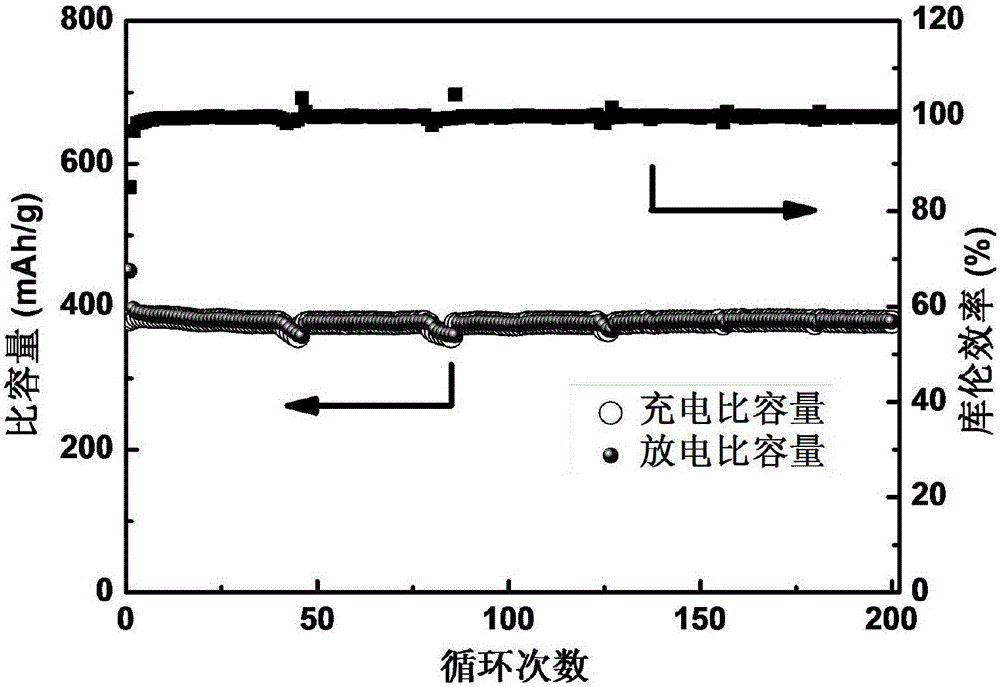

[0033] This embodiment provides a sodium-ion battery.

[0034] The composition of the negative electrode material of the sodium ion battery (based on the mass fraction of the negative electrode material as 100%): 80% of bismuth powder, 10% of conductive carbon black, and 10% of polyvinylidene fluoride.

[0035] The counter electrode of a sodium-ion battery is sodium metal.

[0036] The solvent of the electrolyte is: tetraethylene glycol dimethyl ether.

[0037] The electrolyte salt is: sodium trifluoromethanesulfonate, and the substance concentration in the electrolyte is 1 mol / L.

[0038] How to make the battery:

[0039] Negative electrode preparation: Weigh each raw material according to the above negative electrode formula, uniformly disperse it in N-methyl-2-pyrrolidone (NMP) solution, prepare a mixed slurry of negative electrode, and coat the slurry on the copper foil of the negative electrode current collector , dried in a vacuum drying oven at 110°C for 10 hours, an...

Embodiment 2

[0048] This embodiment provides a sodium-ion battery.

[0049] The composition of the negative electrode material of the sodium ion battery (based on the mass fraction of the negative electrode material as 100%): 80% of bismuth powder, 10% of conductive carbon black, and 10% of polyvinylidene fluoride.

[0050] The counter electrode of a sodium-ion battery is sodium metal.

[0051] The solvent of the electrolyte is: triethylene glycol dimethyl ether

[0052] The electrolyte salt is: sodium trifluoromethanesulfonate, and the substance concentration in the electrolyte is 1 mol / L.

[0053] How to make the battery:

[0054] Negative electrode preparation: Weigh each raw material according to the above negative electrode formula, uniformly disperse it in N-methyl-2-pyrrolidone (NMP) solution, prepare a negative electrode mixed slurry, and coat the slurry on the negative electrode current collector copper foil Then, it was dried in a vacuum drying oven at 110° C. for 10 hours, an...

Embodiment 3

[0061] This embodiment provides a sodium-ion battery.

[0062] The composition of the negative electrode material of the sodium ion battery (calculated based on the mass fraction of the negative electrode material as 100%): 80% of bismuth, 10% of conductive carbon black, and 10% of polyvinylidene fluoride.

[0063] The counter electrode of a sodium-ion battery is sodium metal.

[0064] The solvent of the electrolyte is: diethylene glycol dimethyl ether

[0065] The electrolyte salt is: sodium trifluoromethanesulfonate, and the substance concentration in the electrolyte is 1 mol / L.

[0066] How to make the battery:

[0067] Negative electrode preparation: Weigh each raw material according to the above negative electrode formula, uniformly disperse it in N-methyl-2-pyrrolidone (NMP) solution, prepare a negative electrode mixed slurry, and coat the slurry on the negative electrode current collector copper foil Then, it was dried in a vacuum drying oven at 110° C. for 10 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Charge specific capacity | aaaaa | aaaaa |

| Charge and discharge current density | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com