Selective photoelectrochemical analysis method for microcystin MC-LR in water

A MC-LR, microcystin technology, applied in the field of photoelectrochemical analysis and environmental detection, can solve the problems of complex sample pretreatment and unsatisfactory accuracy, and achieve improved photoelectrochemical performance, good selectivity and sensitivity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

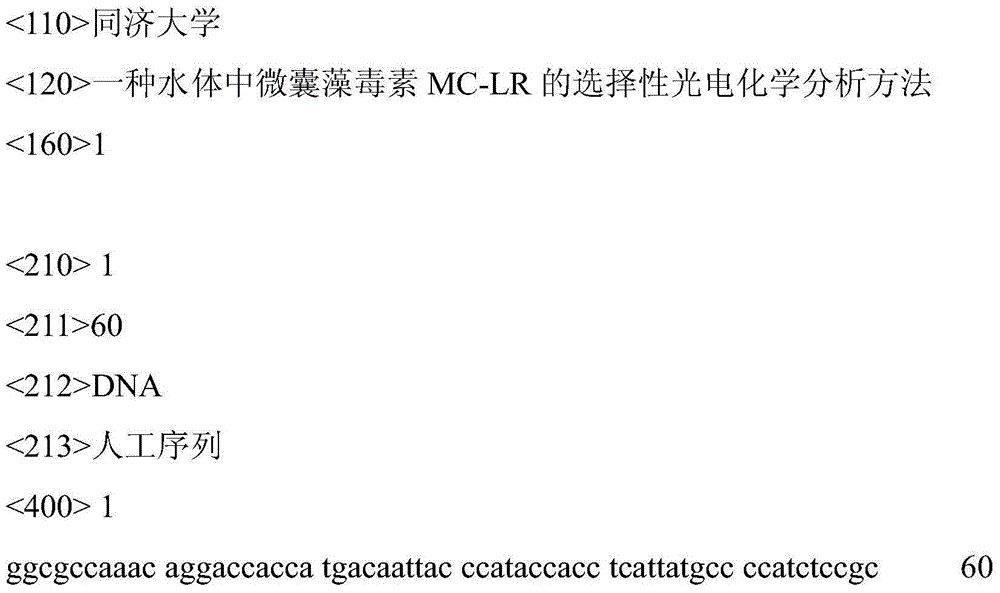

Image

Examples

Embodiment 1

[0033] A new method for selective photoelectrochemical analysis of microcystin MC-LR in water, the specific preparation process of the working electrode is as follows:

[0034] (1) Synthesis of alkyne-modified graphene (G-alkyne): Graphene oxide (GO) was prepared by the Hummers method, prepared into a 2g / L aqueous solution, ultrasonically dispersed for 3h, and then added with a concentration of 1v / v% N 2 h 4 ·H 2 GO is reduced by O, and the NH 3 ·H 2 O adjusted the pH of the mixture to 11.00, and the mixture was stirred and reacted at 90° C. for 1 h. Then 4-ethynylaniline and isoamyl nitrite were added to make the concentrations respectively 0.5wt% and 0.6v / v%, and the mixture was stirred vigorously at 80°C overnight. Then cooled to room temperature, centrifuged and filtered. The filtrate was washed with deionized water and dilute HCl until the filtrate was clear, and dried under vacuum at 50 °C overnight.

[0035] (2) Graphene on TiO 2 Assembly of the surface of NTs: A...

Embodiment 2

[0039] Using the traditional three-electrode system, the Aptamer / G / TiO prepared in Example 1 2 NTs is the working electrode, the saturated calomel electrode is the reference electrode, the platinum wire electrode is the counter electrode, and 0.1M PBS buffer solution with a pH of 7.4 is used as the supporting electrolyte. Different concentrations of MC-LR standard solutions are added to the system to control the MC- The interaction time between LR and aptamer was 45min at room temperature. Under the excitation of visible light, a bias voltage of 0.3V was applied, and the photocurrent of the system containing different concentrations of MC-LR was measured by I-t curve method, which was converted into photocurrent density (j) according to the working area of the electrode. Within a certain range of MC-LR concentration, as the concentration of MC-LR increases, the photocurrent density also increases correspondingly. Part of the aptamer is caused to dissociate from the electrod...

Embodiment 3

[0041] Aptamer / G / TiO prepared with 2 NTs were used as working electrodes, saturated calomel electrodes were used as reference electrodes, platinum wire electrodes were used as counter electrodes, and 0.1M PBS buffer solution with pH 7.4 was used as supporting electrolyte. Apply 0.3V bias voltage under visible light excitation, and use I-t curve method to measure the photocurrent of 99.5pg / L MC-LR solution and interfering substance system respectively. The interfering substance system is a mixed solution of MC-LR and interfering substance. The concentration of MC-LR in the system is 99.5pg / L, the concentration of interfering substances is 100 times of the molar concentration of MC-LR, and the relative photocurrent ratio (R) is calculated to obtain the selectivity of the sensor. Interfering substances include monosultap, atrazine, glyphosate, omethoate, paraquat, trichlorfon, and acetamidin. The results show that when interfering substances are monosultap, atrazine, glyphosate,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com