Preparation method of super-hydrophobic self-cleaning solar cell glass cover plate of deep space exploration

A glass cover and deep space detection technology, applied in photovoltaic power generation, electrical components, photovoltaic modules, etc., can solve the problems of loss of self-cleaning function, failure to guarantee repeated mass production of products, etc., achieve excellent self-cleaning effect, and simple manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

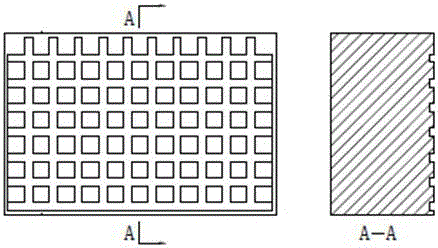

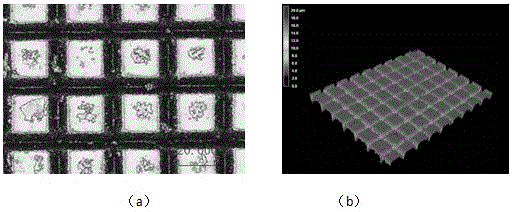

[0021] 1. Clean and dry the solar cell cover glass first, and then use a femtosecond laser to etch the surface of the glass cover with a specific shape (such as figure 1 shown), using a femtosecond laser with a power of 1w and a wavelength of 355 nm to etch the surface of the cover glass, the grooves shown are criss-cross channels with a width of 10 µm, a depth of 7 µm, and a pitch of 20 µm; After etching is completed, as figure 2 The microstructure morphology shown in (a) and (b) contains uniform groove channels, and the water droplets on the surface are tiled, showing a superhydrophilic state.

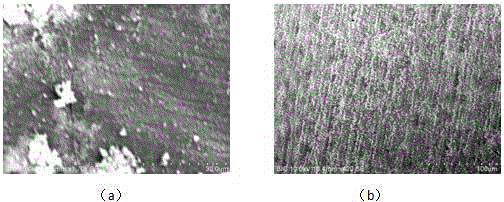

[0022] 2. Put the etched glass cover into a polytetrafluoroethylene reactor with built-in concentrated ammonia water (content 25-28%), and react in an oven at 120°C for 5 hours. After the reaction is completed, take it out and wash it with deionized water , put in 0.1g of SiO with a particle size of 300 nm 2 The 1:8:1 (mass ratio) tetraethyl orthosilicate:alcohol:water mixed solut...

Embodiment 2

[0025] 1. Clean and dry the cover glass of the solar cell first, and then use a femtosecond laser to etch the surface of the cover glass. Use a femtosecond laser with a power of 1w and a wavelength of 355 nm to etch the surface of the cover glass, as shown The grooves are criss-cross channels, the groove width is 20 µm, the depth is 15 µm, and the spacing is 20 µm; it contains uniform groove channels, and the water droplets on the surface are tiled, showing a super-hydrophilic state;

[0026] 2. Put the etched glass cover into a polytetrafluoroethylene reactor with built-in concentrated ammonia water (content 25-28%), and react in an oven at 160°C for 2 hours. After the reaction is completed, take it out and wash it with deionized water , the configuration contains 0.4g of SiO with a particle size of 7-40 nm 2 A mixed solution of tetraethyl orthosilicate:alcohol:water with a mass ratio of nanoparticles of 1:6:1 was used to spin-coat a glass sheet with the above-mentioned solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com