A preparing method of a magnetic hydrogel microsphere

A technology of gel microspheres and magnetic water, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve problems such as difficult large-scale production, low adsorption rate, and low preparation efficiency, and achieve easy scale efficient production, easy separation, and improved adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

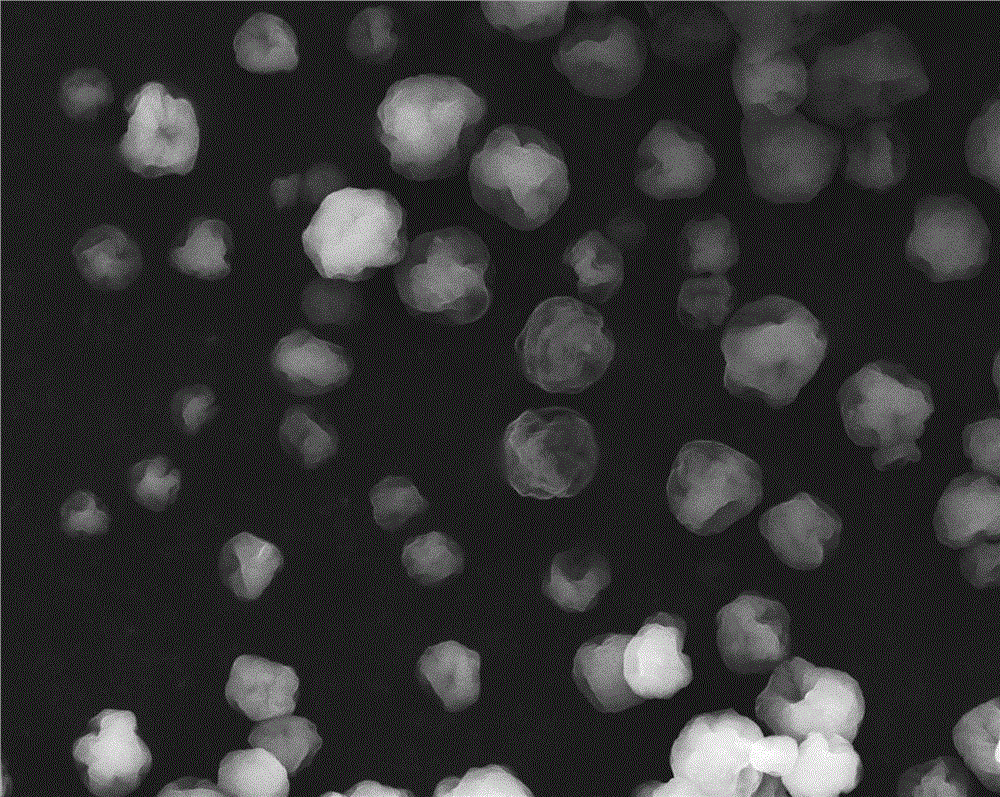

[0021] (1) Ultrasonic dispersion of 0.5 g of graphite oxide prepared by the Hummers method in 100 mL of deionized water to obtain a GO dispersion with a concentration of 5 mg / mL. Then, under a nitrogen atmosphere, 1.5 g of iron salt (Fe 2+ and Fe 3+ The molar ratio is 1:2) and 0.2g NaOH solution for 30 min to get GO@Fe 3 o 4 The mixture was centrifuged and dried for use.

[0022] (2) Dissolve 5 g of CMC in 500 mL of distilled water at 60 °C, and then add 0.435 g of GO@Fe into it 3 o 4 and 0.2 g of citric acid, ultrasonically dispersed and magnetically stirred for 3 h, and then prepared GO@Fe by spray dryer 3 o 4 CMC composite microspheres with 8wt% content, marked as CMC / GO@Fe 3 o 4 . The parameters of the spray drying device are set to an inlet temperature of 150-160 °C, an injection volume of 600-800 mL / h, and an air flow rate of 80-90%. Finally, the obtained composite microspheres were dried in an oven at 90 °C for 5 h and then sealed for use.

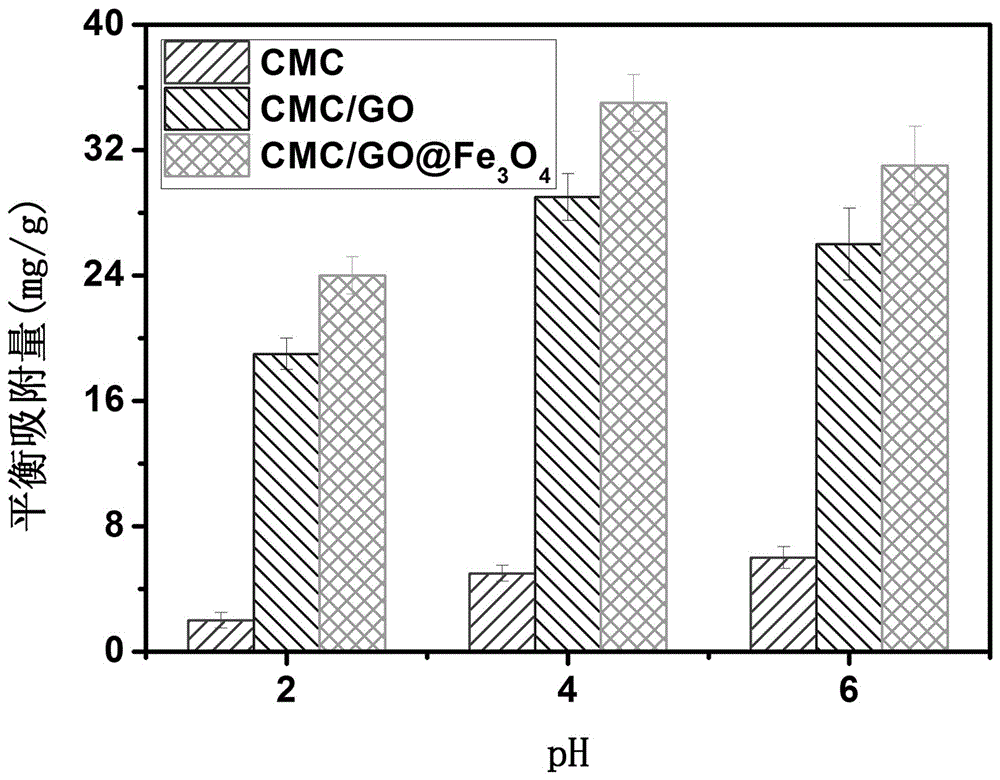

[0023] In addit...

Embodiment 2

[0026] In Example 2, CMC / GO@Fe was prepared in the same manner as in Example 1 3 o 4 Composite hydrogel microspheres, the only difference is the GO@Fe composite microspheres in this example 3 o 4 The content is 2 wt%. The results showed that the adsorption capacity of the hydrogel microspheres in this example to hexavalent chromium ions was 9 mg / g at pH=4.

Embodiment 3

[0028] In Example 3, CMC / GO@Fe was prepared in the same manner as in Example 1 3 o 4 Composite hydrogel microspheres, the only difference is the GO@Fe composite microspheres in this example 3 o 4The content is 4 wt%. The results showed that the adsorption capacity of the hydrogel microspheres in this example to hexavalent chromium ions was 17 mg / g at pH=4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com